The PEI History of Innovation, Expertise, and Reliability

Photofabrication Engineering, Inc. (better known as PEI) is a company that takes great care and pride in delivering precision-etched metal parts using sophisticated chemistry and expert manufacturing. It’s been like that since our earliest days in 1968 to today.

We strive to answer every customer challenge with efficiency, quality, and speed. We’ve grown from a 4,000-square-foot building to a 40,000-square-foot facility. We’ve evolved from serving customers in the semiconductor and computer peripherals industries to providing mission-critical parts and components to the renewable energy, aerospace, and defense markets.

We’ve built a strong reputation by understanding our customers’ needs and helping to maximize their businesses.

PEI’s History

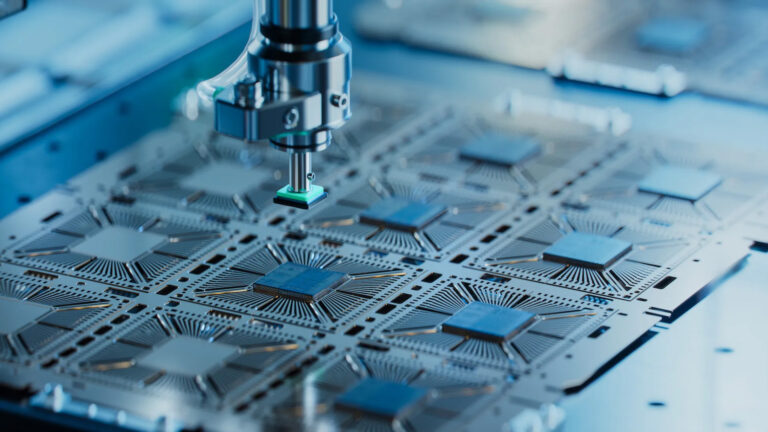

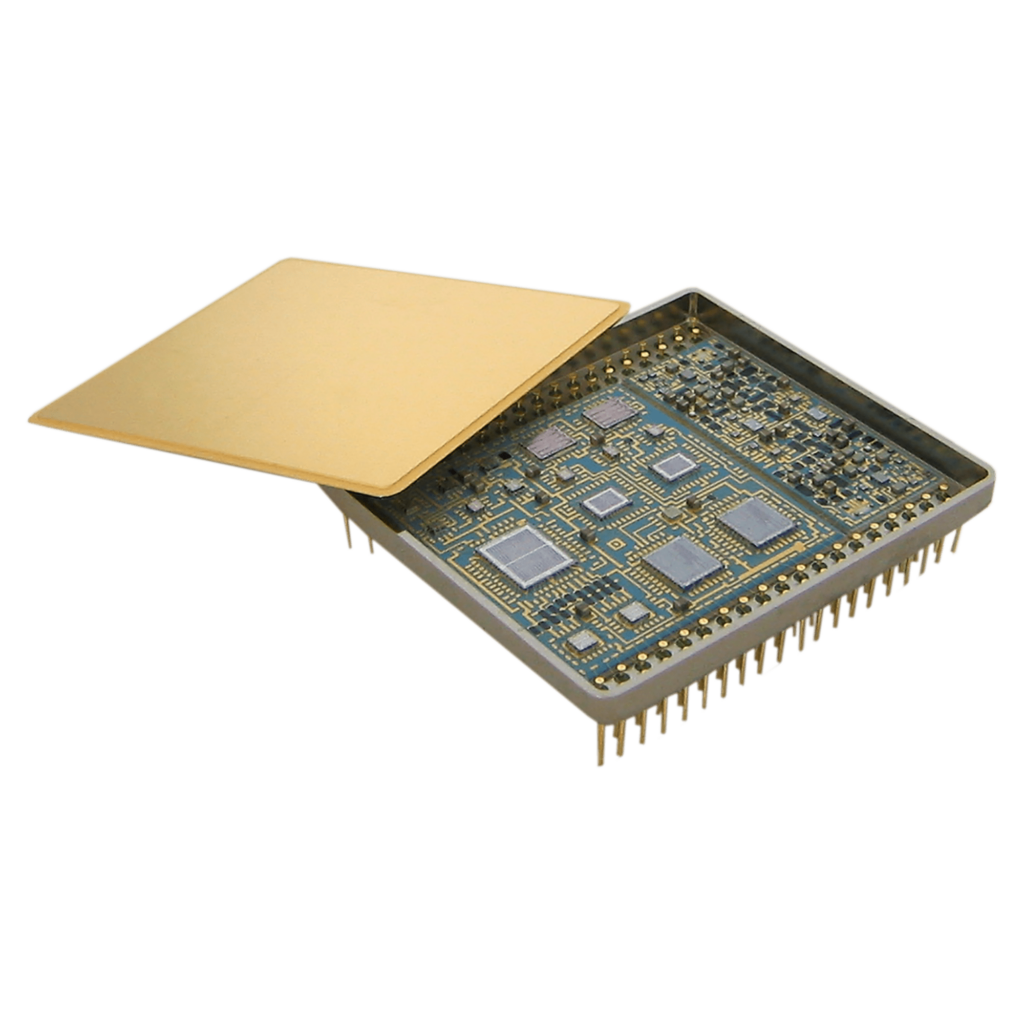

PEI opened its doors in Holliston, MA, in 1968. We answered early calls from leading semiconductor and computer peripheral companies who needed a resource for precision metal parts essential for use in high-technology applications.

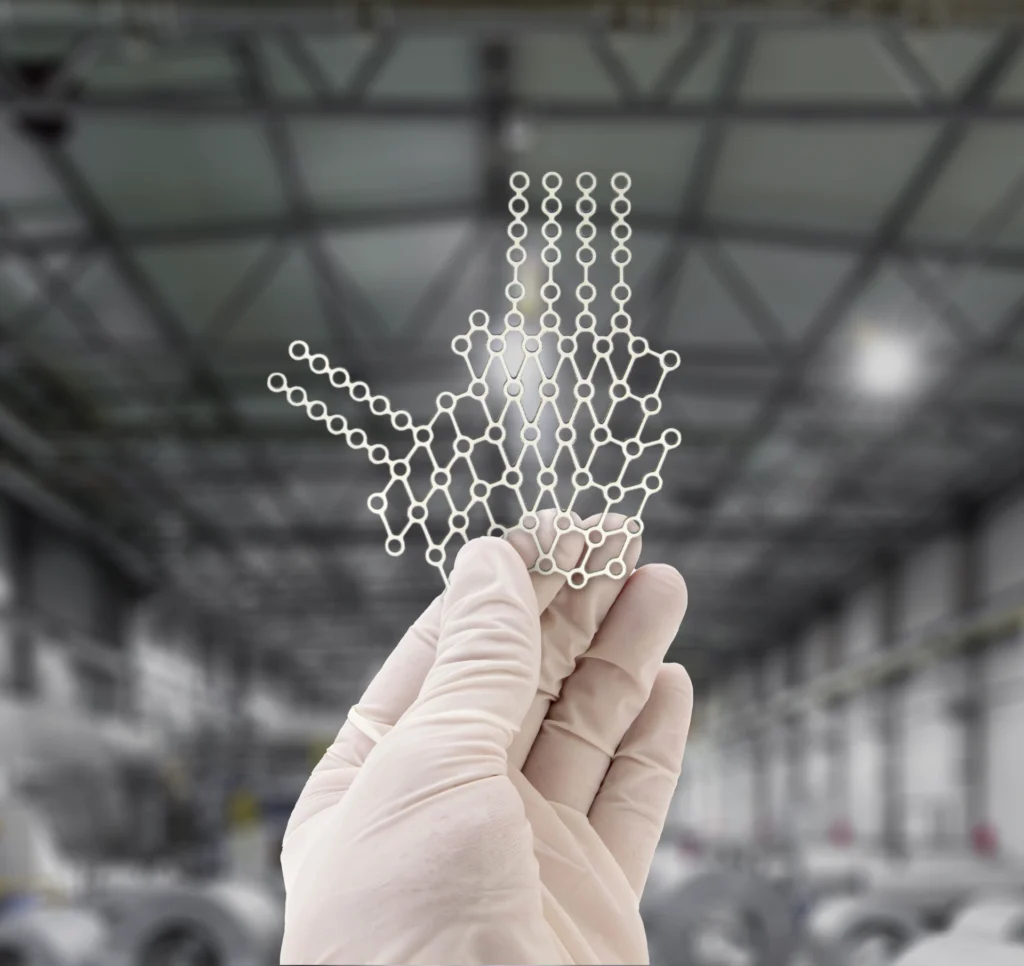

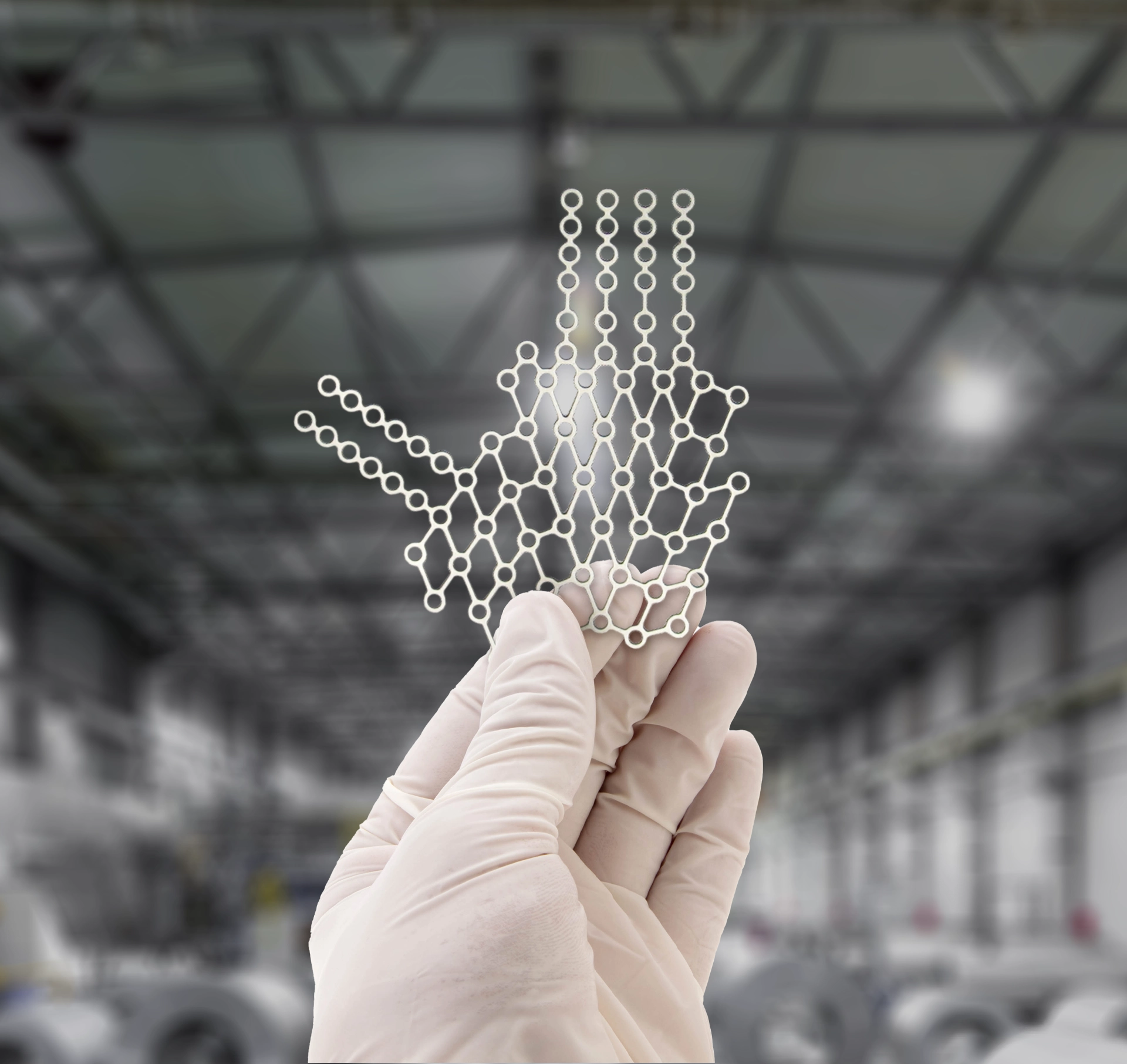

Our budding expertise in photochemical machining (or photochemical etching) — a process that delivers precise, durable, and reliable thin metal parts via design, photo-tooling, and etching — was an optimal solution for the high-tech sector.

As companies understood that more precise and durable parts were possible with photochemical machining, our opportunities, and business began to grow.

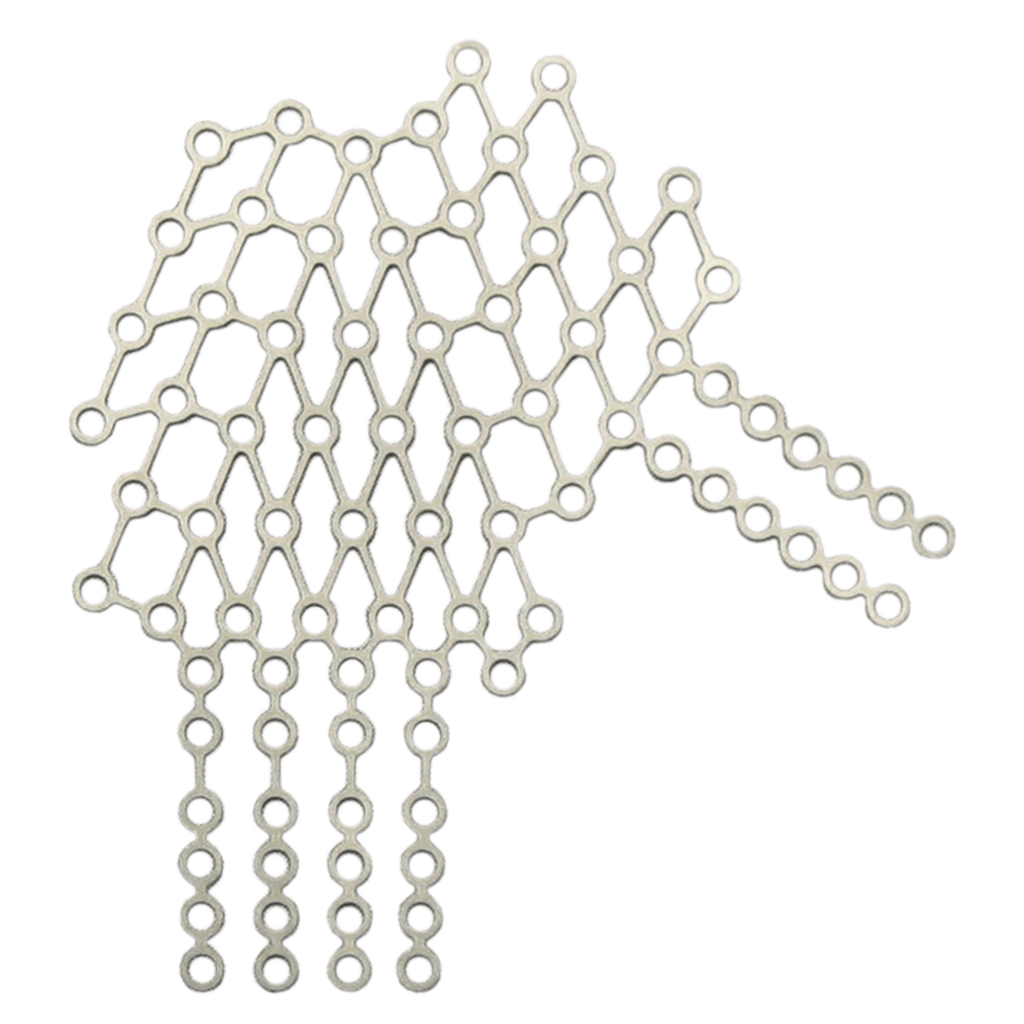

One market that opened to early-stage PEI was the decorative and jewelry industry. PEI launched its Decorative Products division in the mid-1970s to service those clients.

By the early 1980s, PEI was outgrowing the 4,000-square-foot building. Company management found real estate in Milford, designed a new plant, purchased additional machinery, and moved in 1984.

The new 40,000-square-foot production center enabled PEI to expand its base of customers, number of employees, and production volume. Efficiencies and expertise continue to fuel year-over-year growth for the company.

New Capabilities,

More Markets

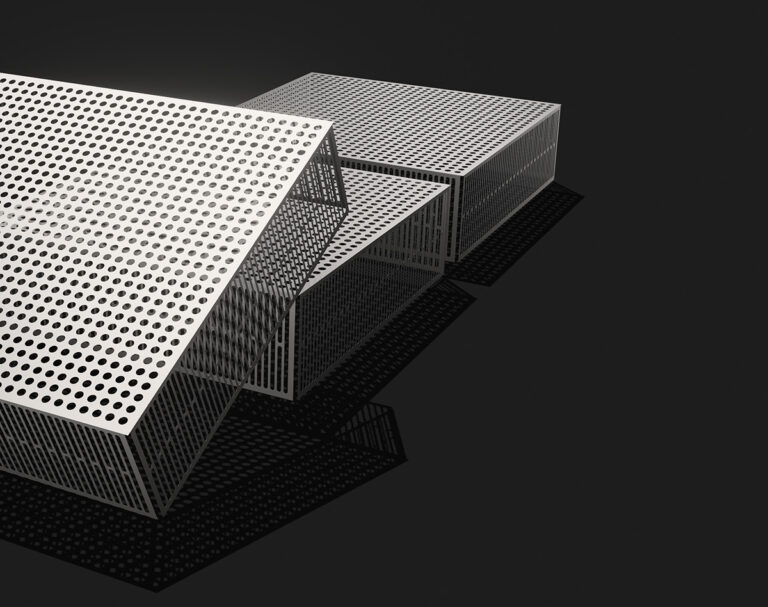

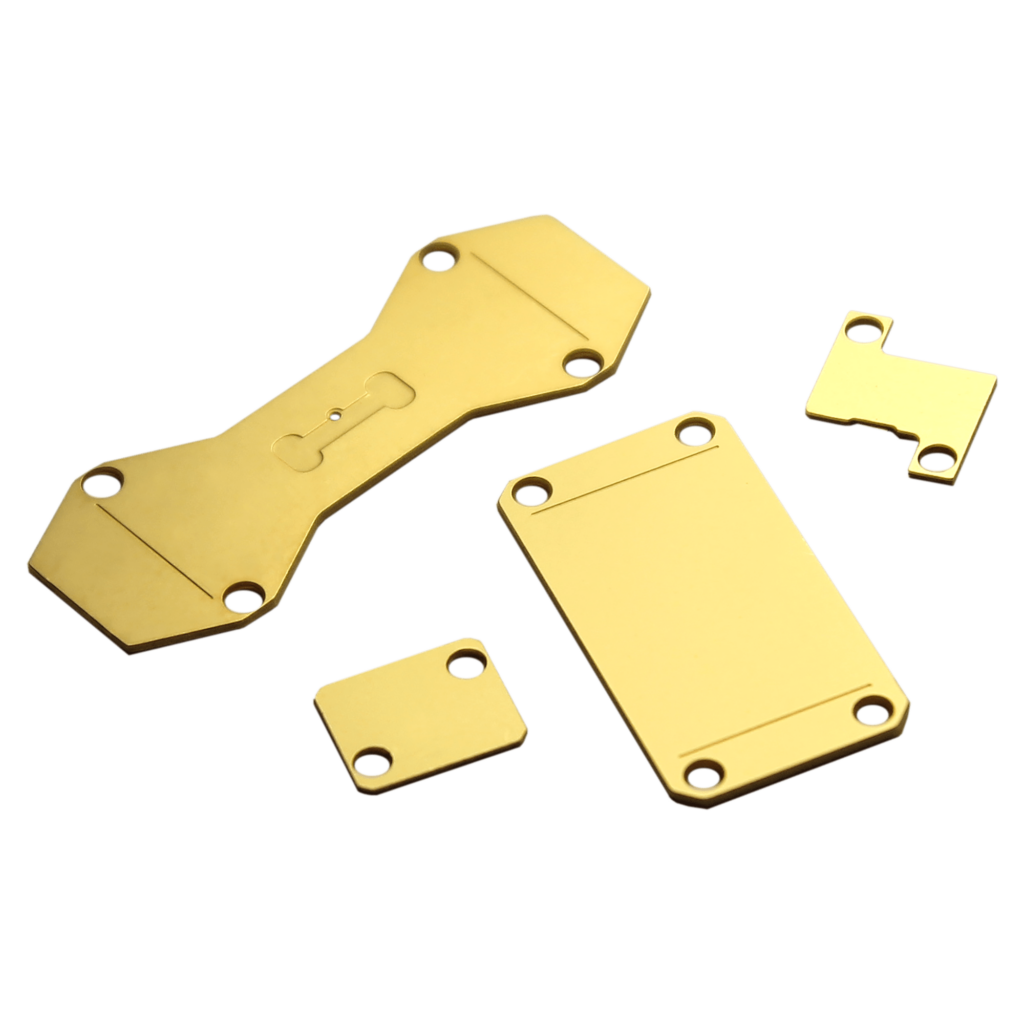

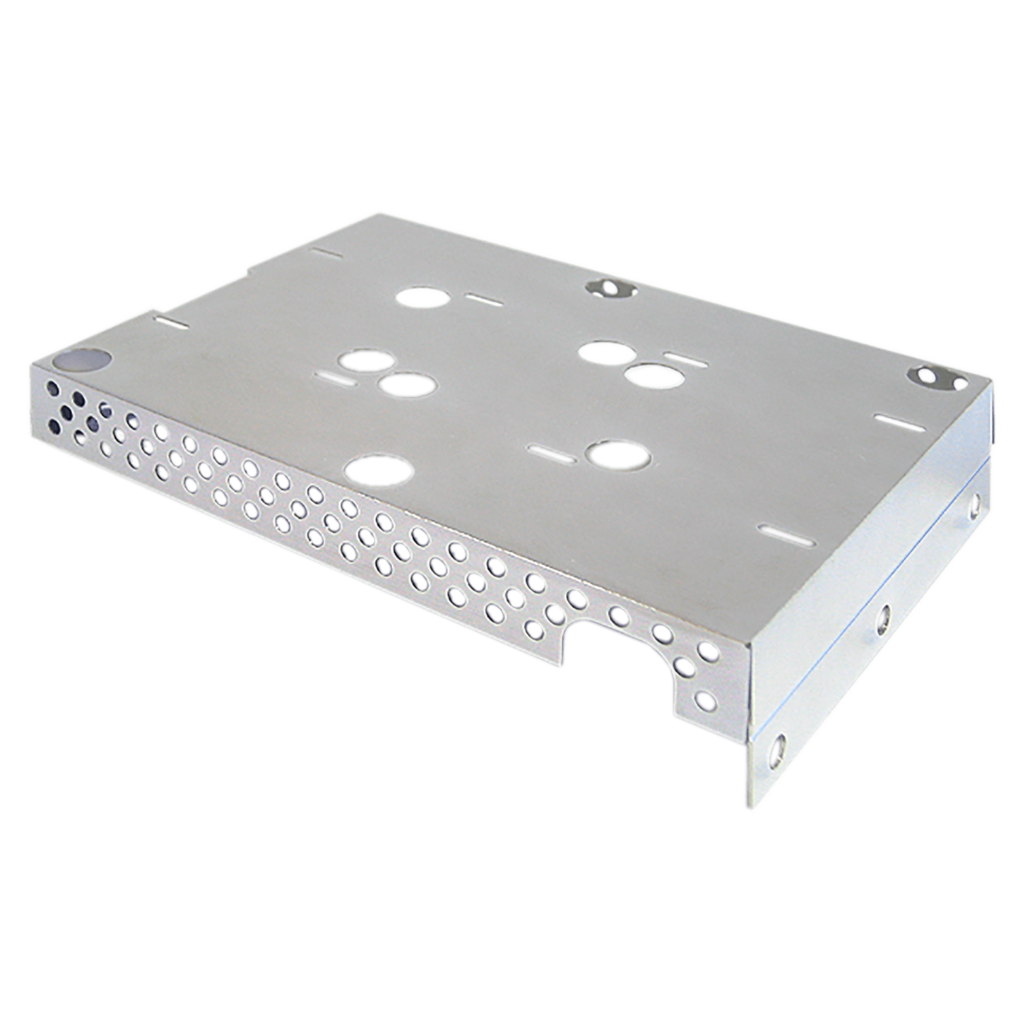

In addition to its expertise in photochemical machining, PEI is known for its proficiency in forming, plating, finishing, and assembly services.

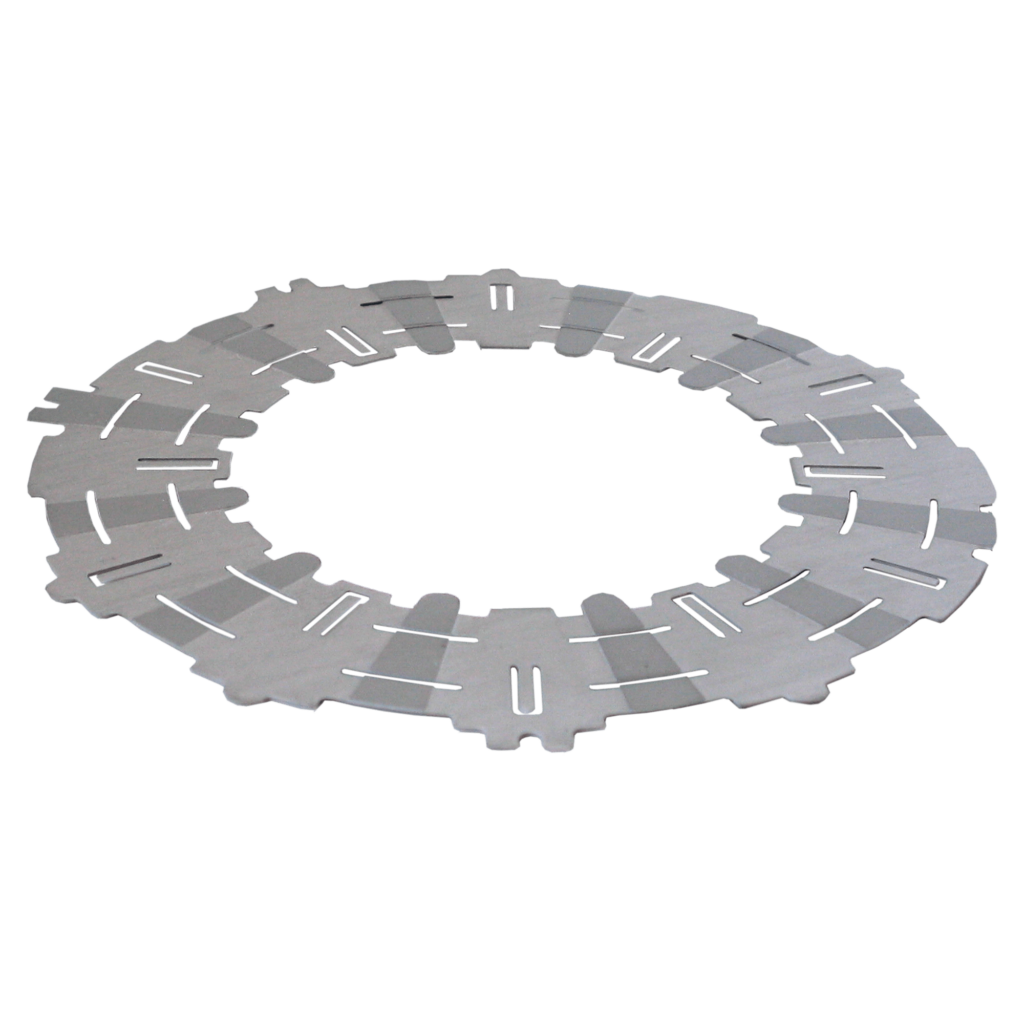

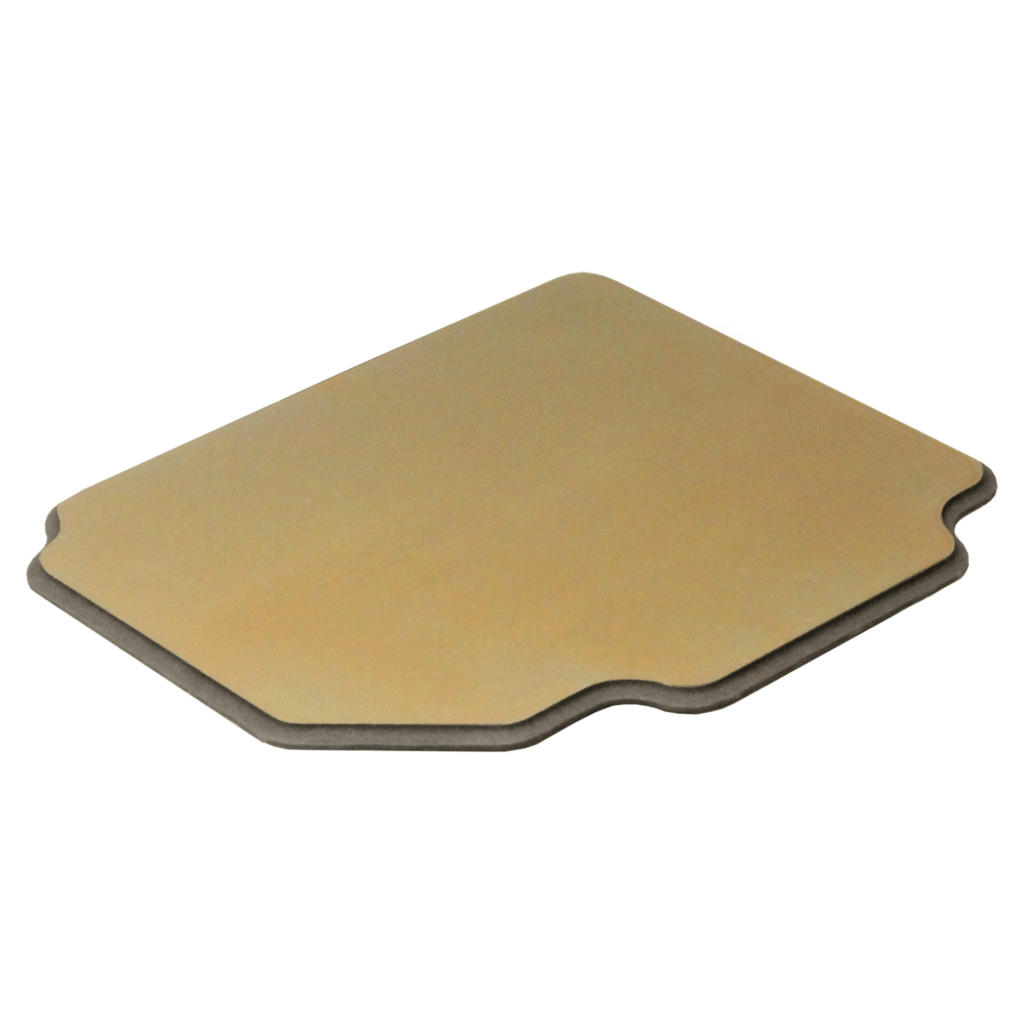

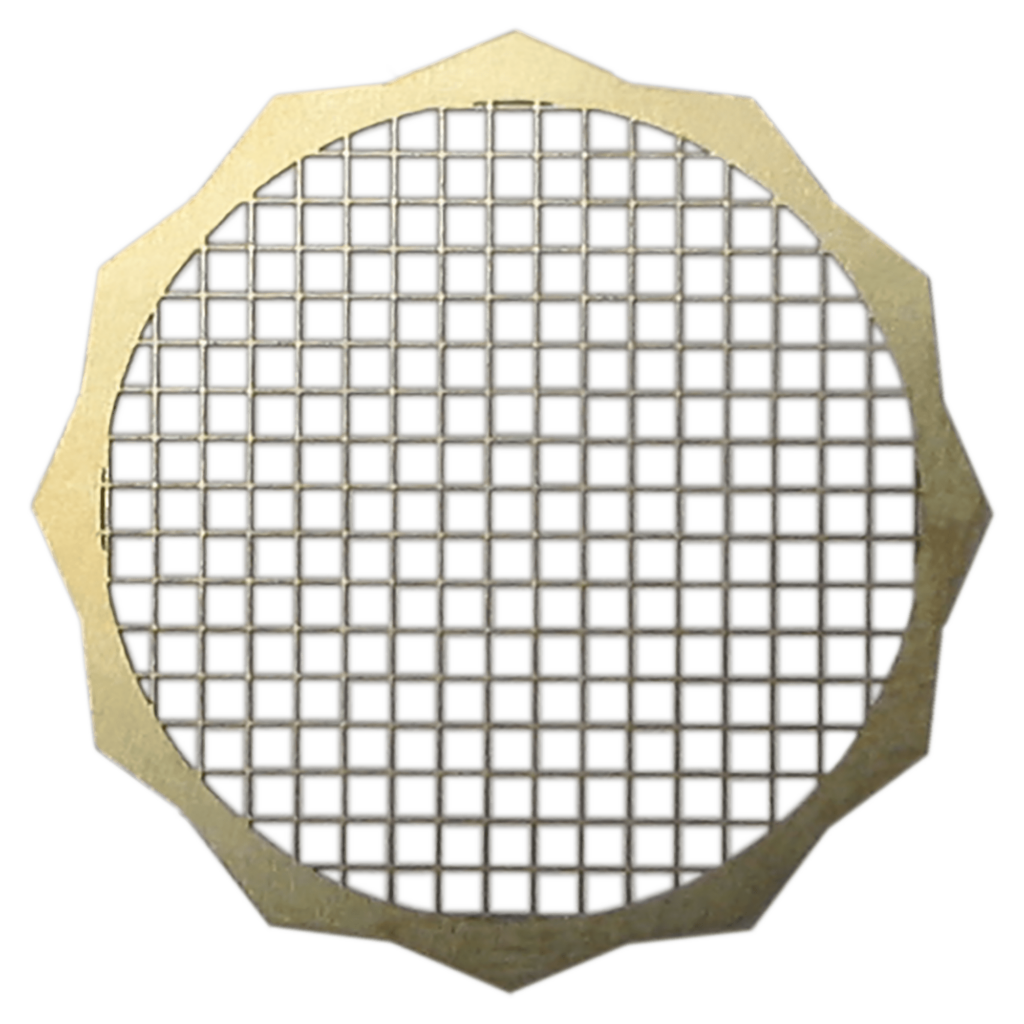

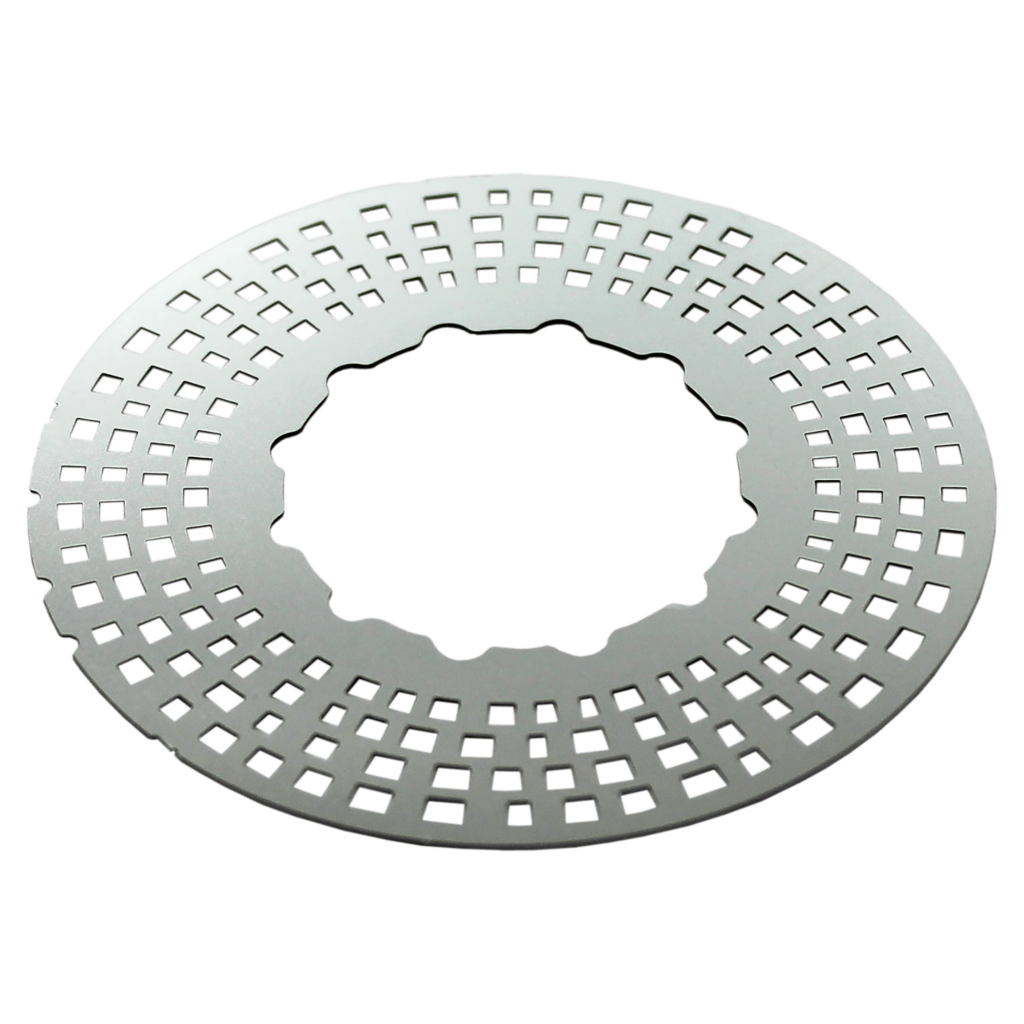

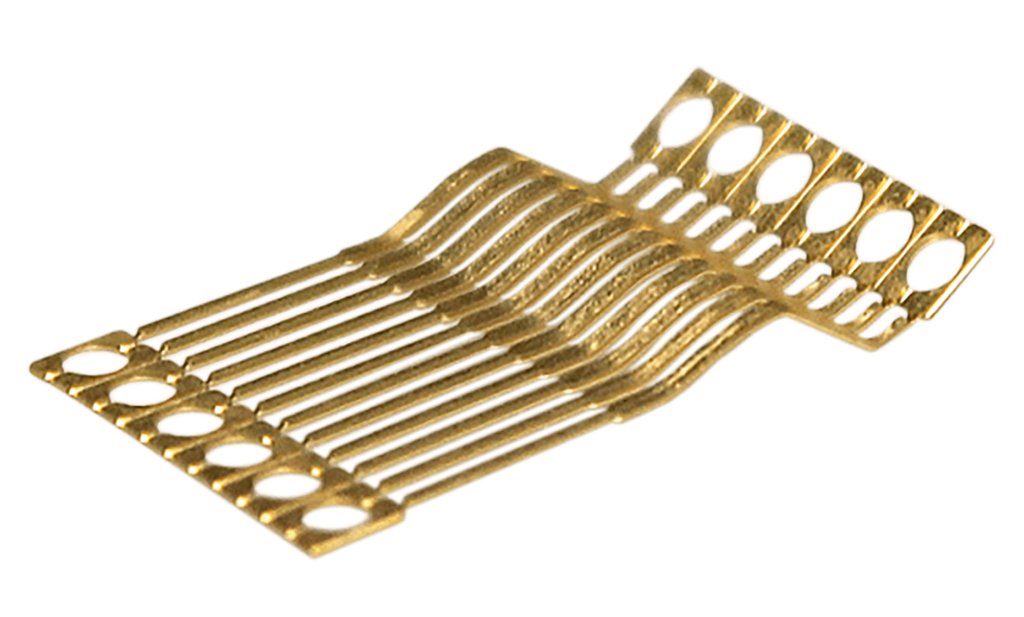

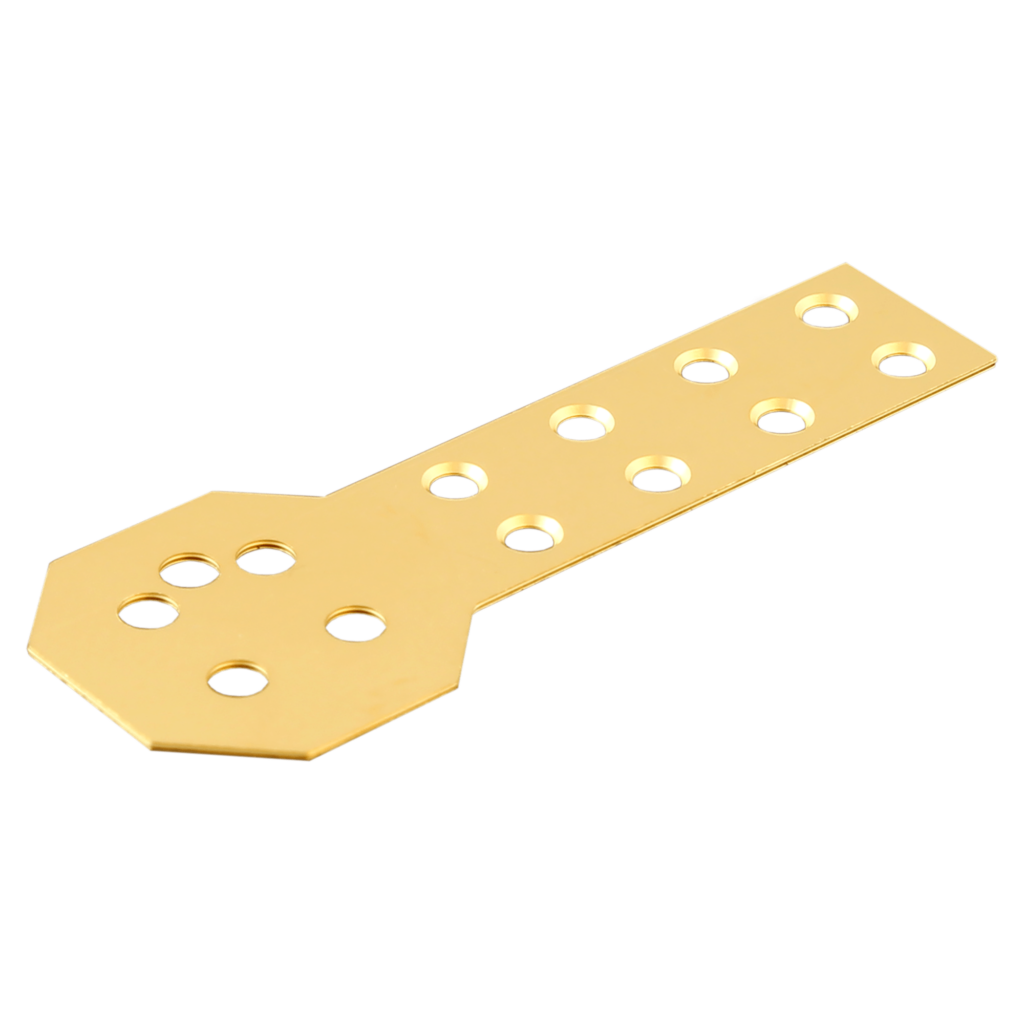

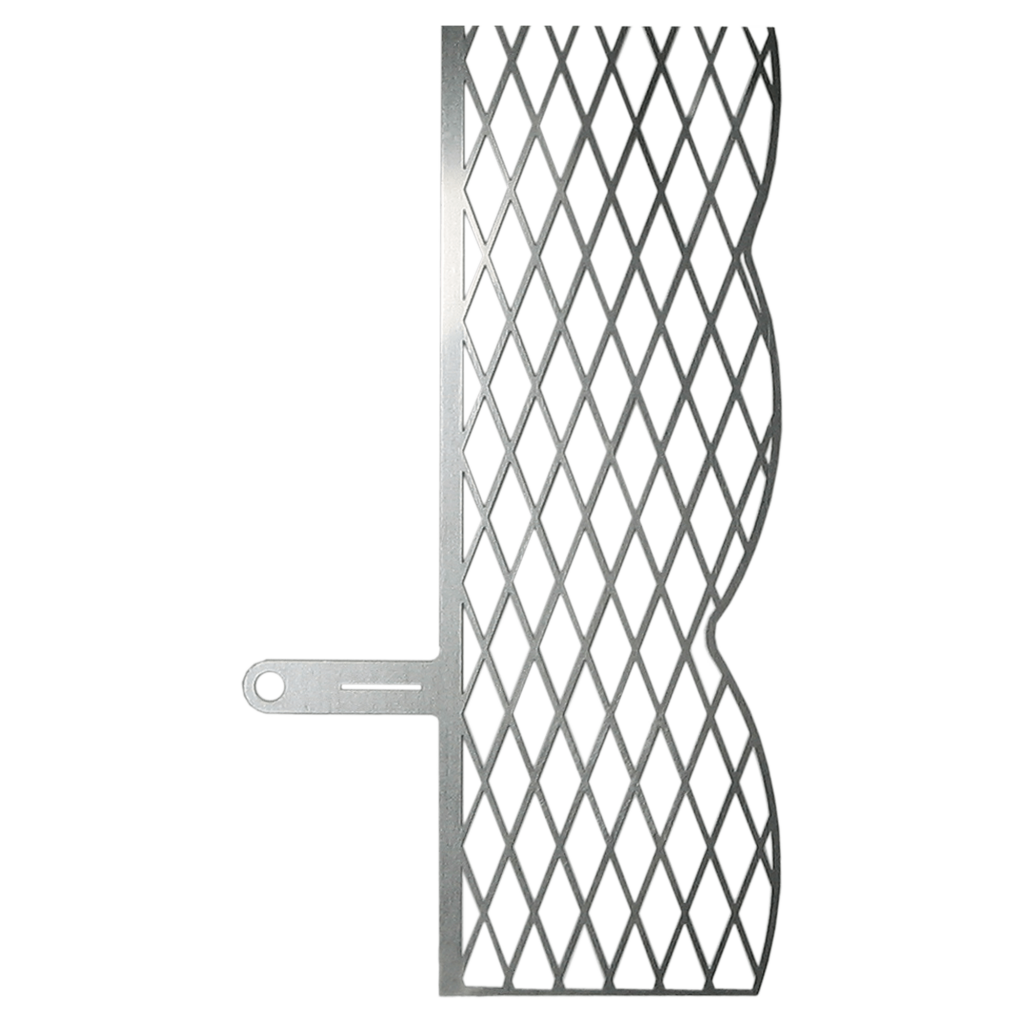

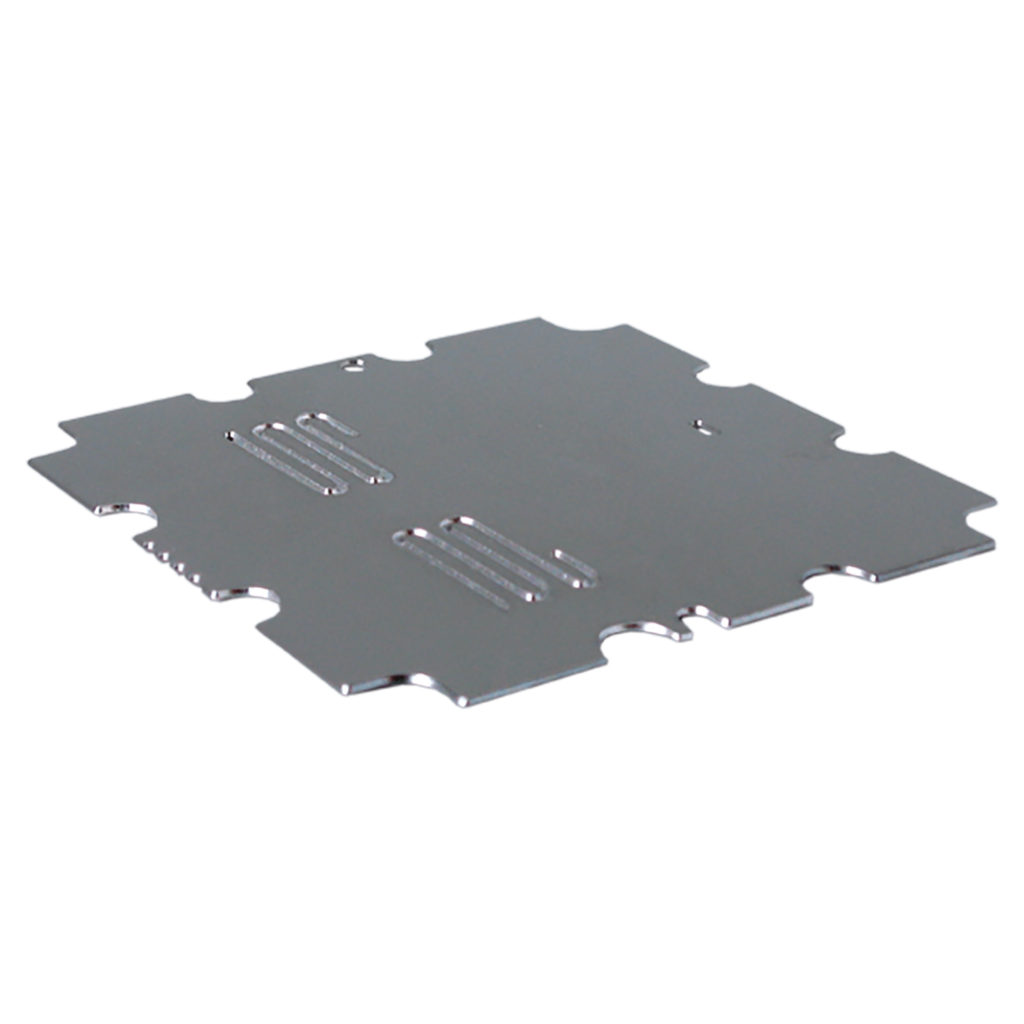

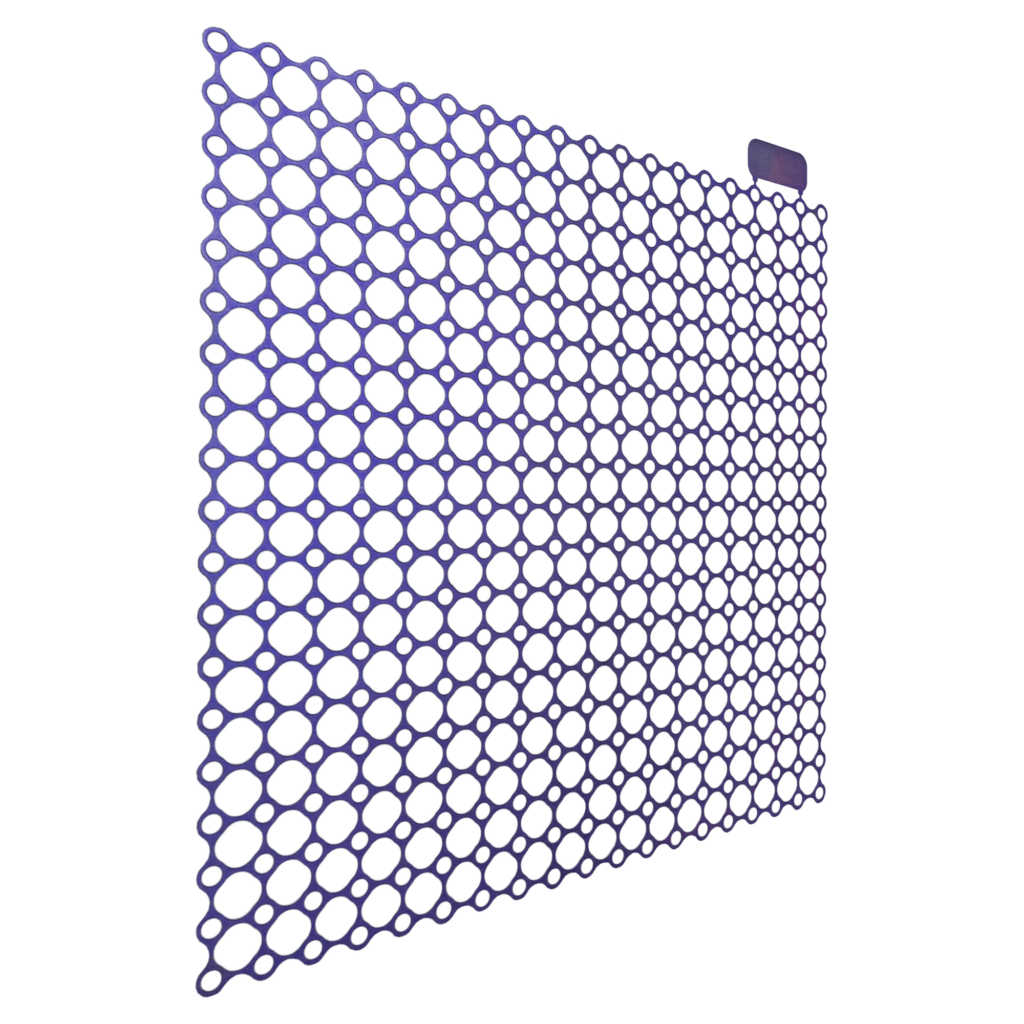

The metal parts manufactured here include bipolar electrolyzer plates, lids & covers, EMI/RF shields, microchannel plates, lead frames, encoder discs, screens, and more. PEI’s experts regularly support custom manufacturing and prototyping requests from clients.

At the same time, PEI’s teams expanded the list of metals we can etch to include titanium, Kovar, nickel, nickel silver, stainless steel, copper, brass, and tin.

In addition to supporting leading automotive, medical, microelectronics, and defense manufacturers, we are expanding into the ever-important renewable sector.

A Focus on Renewable

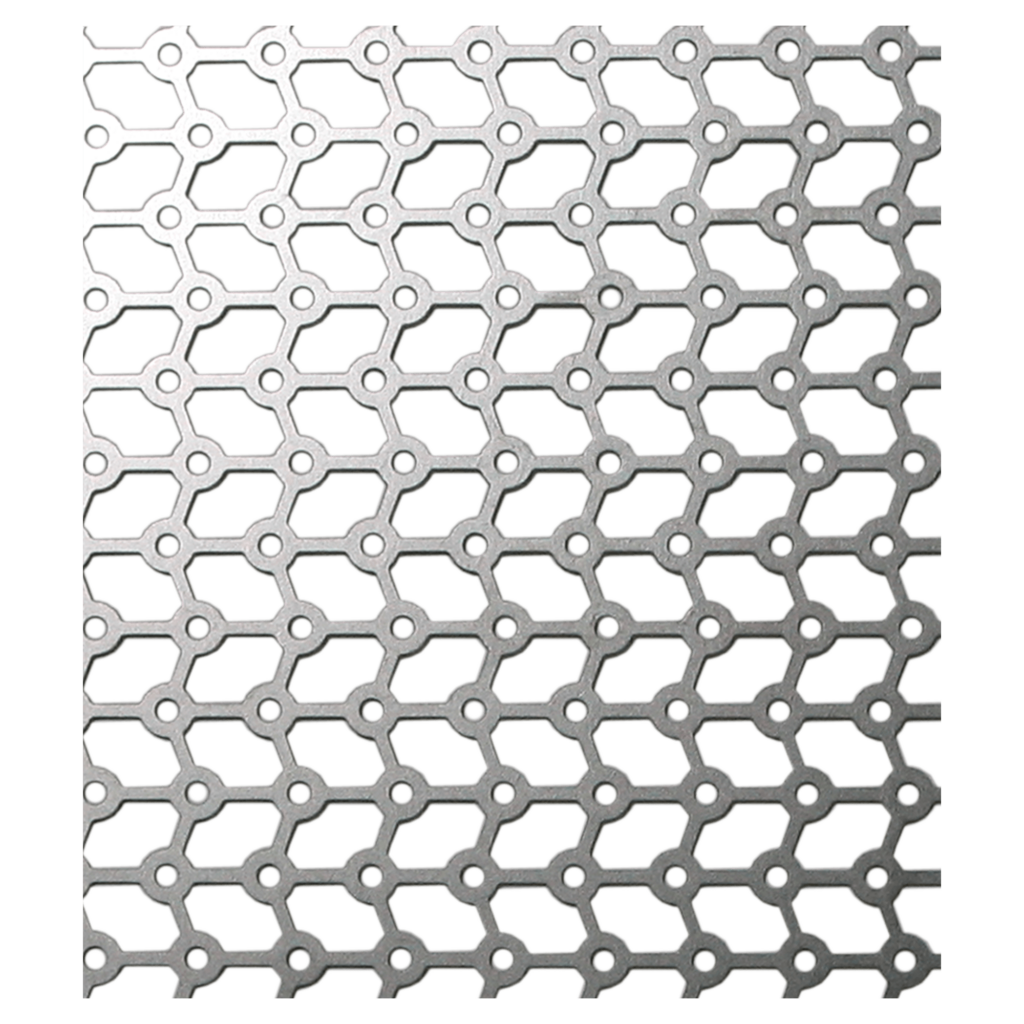

Developing expertise in photochemical machining titanium opened the door to opportunities for companies building components for renewable energy applications.

Our team was an early R&D and prototyping resource for companies searching for greener energy options, including hydrogen, solar, and wind.

Our prototyping work with one such company led to the development of titanium bipolar electrolyzer plates, a part that separates hydrogen from water.

The hydrogen created from this process can be used in many ways — directly injected into gas grids, used in fuel and green chemicals production, and used in hydrogen fuel cell applications for trains, buses, and trucks. It is easy to store, offers reliable mobility, and is a great way to transport power. It can be shipped via tankers or pipelines, making it an excellent carbon-free energy source for areas that do not have access to renewable energy sources.

We are working with several companies pushing the possibilities of renewable energy. It’s exciting and hopeful for us all.

Joining The Partner Companies

The Partner Companies acquired PEI in April of 2021.

“PEI is a gem we’ve been pursuing for many years,” says Dan Brumlik, Co-Chairman of The Partner Companies. “They’re a standard bearer in capability and customer service. PEI’s expertise is a strong complement to TPC’s menu of capabilities, and their leadership team brings a robust knowledge of the manufacturing process.”

As part of TPC’s platform of specialty manufacturers, PEI shares design, engineering, manufacturing, and supply chain expertise with nine operating companies. The combination of PEI’s vast expertise and TPC’s diverse capabilities provides customers with a broad range of services and business continuity peace of mind.