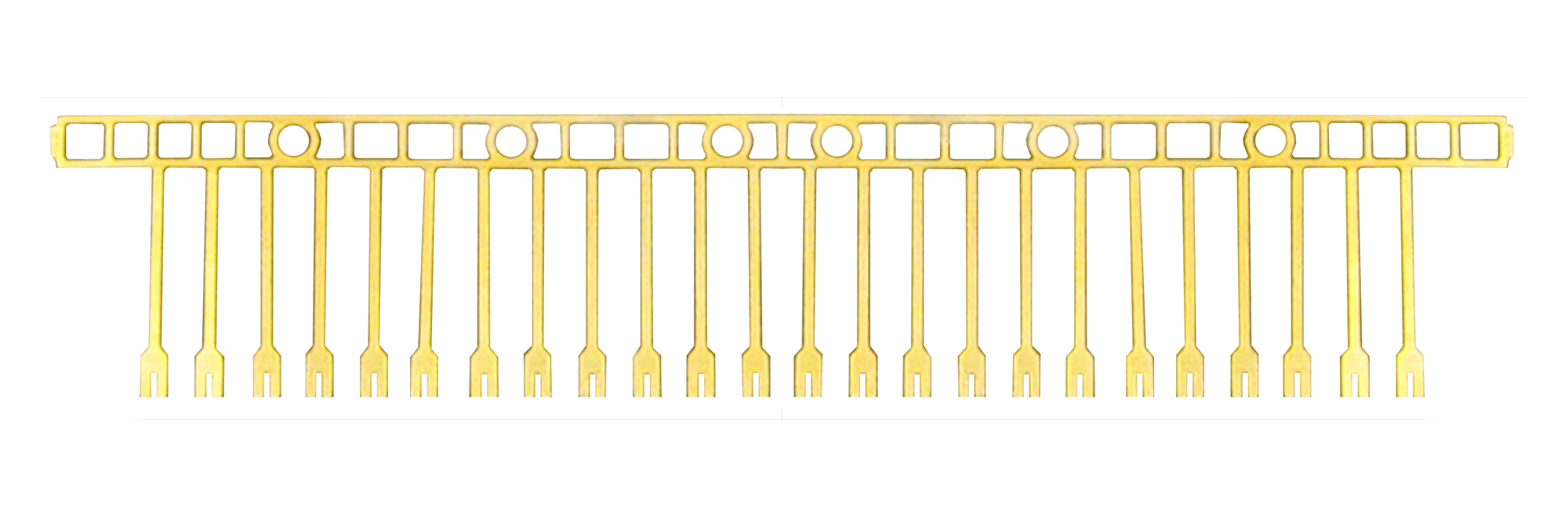

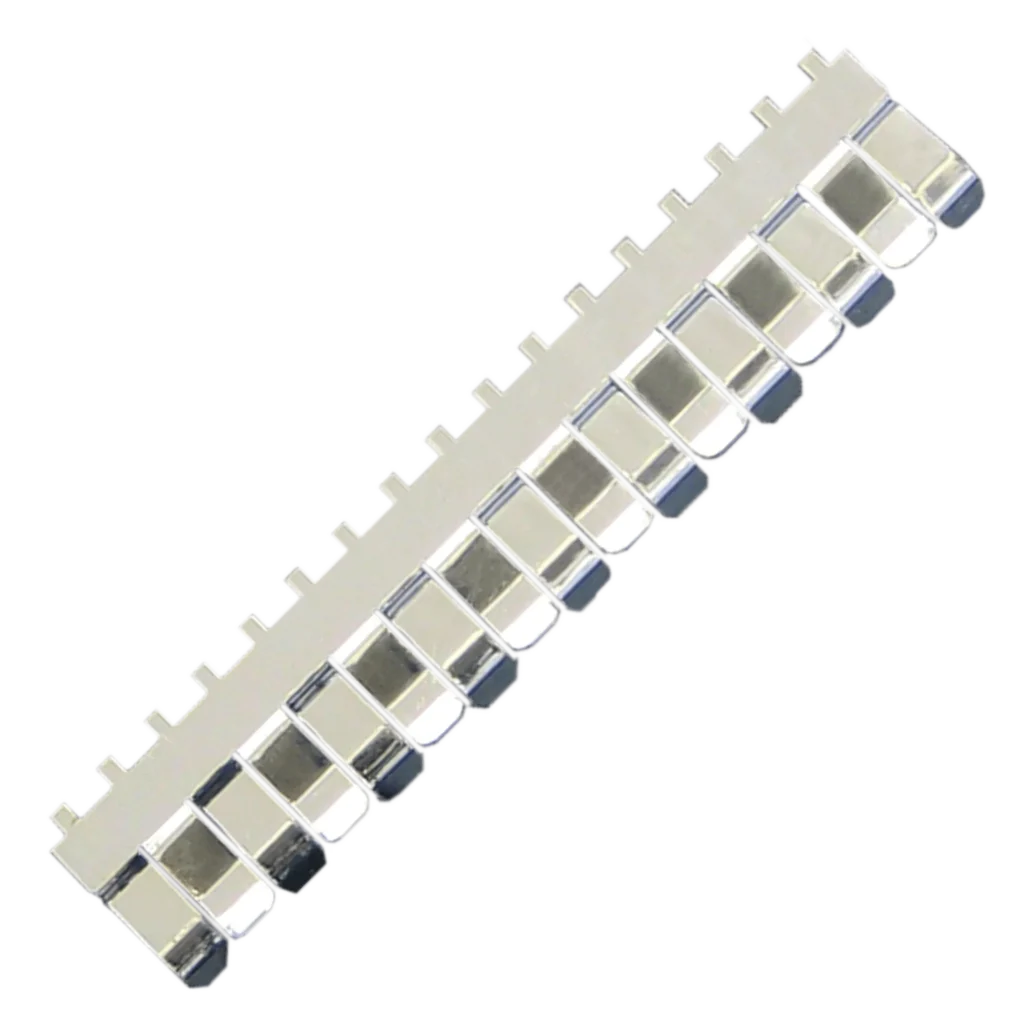

Powering parts and components takes expert engineering and precision manufacturing, especially when the job is to ensure consistent electrical conductivity in demanding environments like advanced electronics systems. Contact strips are the thin metal parts that make it happen.

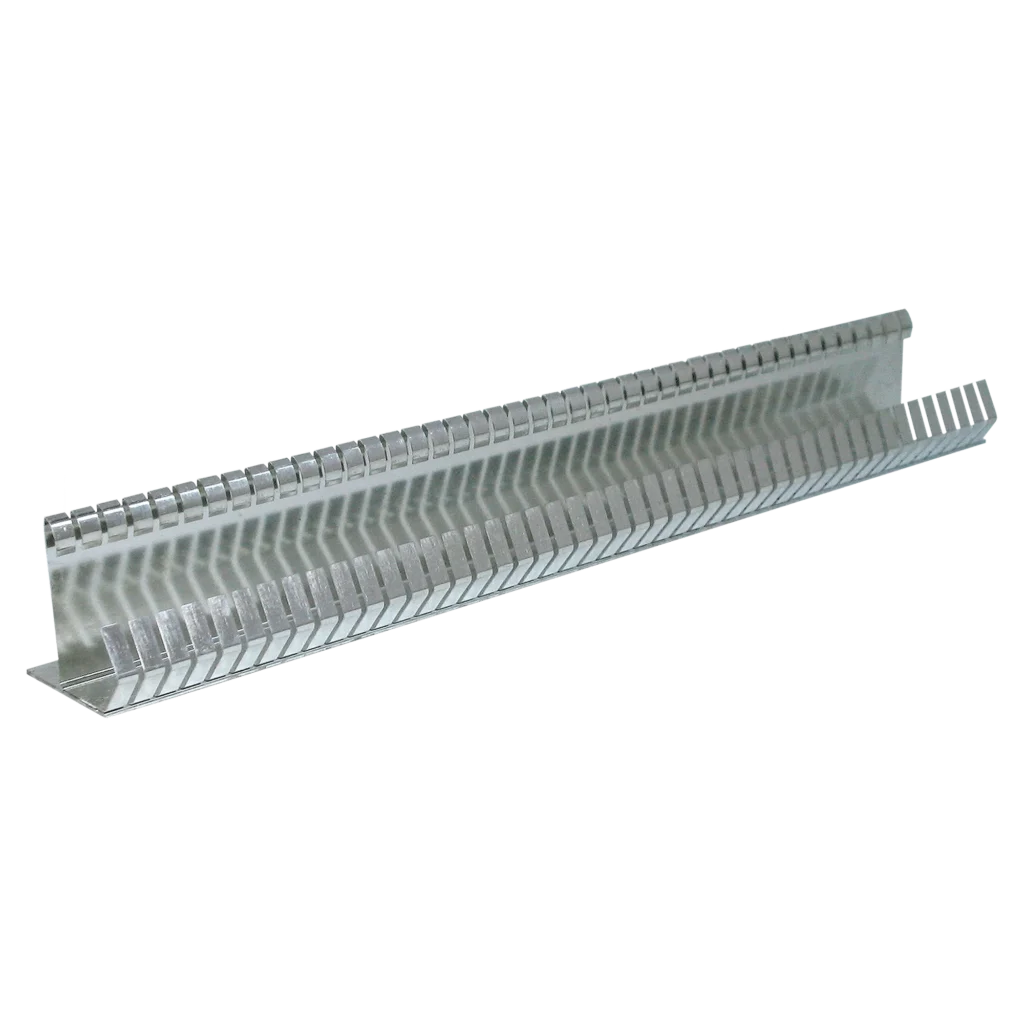

PEI is a leading manufacturer of precision contact strips that maintain dimensions and integrity under thermal stress while offering superior oxidation and corrosion resistance. Industry-leading manufacturing companies rely on PEI’s contact strips for a range of high-reliability applications across the world’s most important industries.

Contact strips are components that facilitate electrical conductivity between two or more points.

Used in thousands of applications, it’s vital that contact strips can withstand demanding environments while ensuring optimal performance.

Because electrical conductivity is essential to the performance of a contact strip, many leading engineers rely on copper, aluminum, or other specialized alloys when designing the thin metal part. While each material has its unique characteristics and benefits, the choice of metal often comes down to component design or use case. Other factors include cost, weight, conductivity, and heat dissipation.

Here are some benefits of each metal:

A widely preferred material used for its excellent electrical conductivity, malleability, and ability to accept nearly any finish

A lightweight metal that features high conductivity, strength, and ability to be shaped into a variety of designs

Contact Strips are found in nearly every electronic or microelectronic component in the world, making them an indispensable component across a diverse range of industries.

As experts in the production of contact strips, PEI serves customers in industries such as:

Defense

Electronics

Telecommunications

Aerospace

Medical

Renewable Energy

Offering robust performance and protection for defense electronics, contact strips ensure reliable operation and environmental protection for sensitive electronic systems in demanding environments. Our contact strips deliver consistent electrical conductivity and resilience, supporting the critical missions of defense forces.

Crucial for advanced electronic devices, our contact strips are engineered to meet exacting standards to enhance device performance, longevity, and miniaturization. They are at the heart of cutting-edge electronic devices by ensuring a robust connection.

Supporting high-speed data transfer in telecommunication infrastructure requires efficient electrical connections from contact strips to ensure reliable and uninterrupted signal transmission, powering the global communication network.

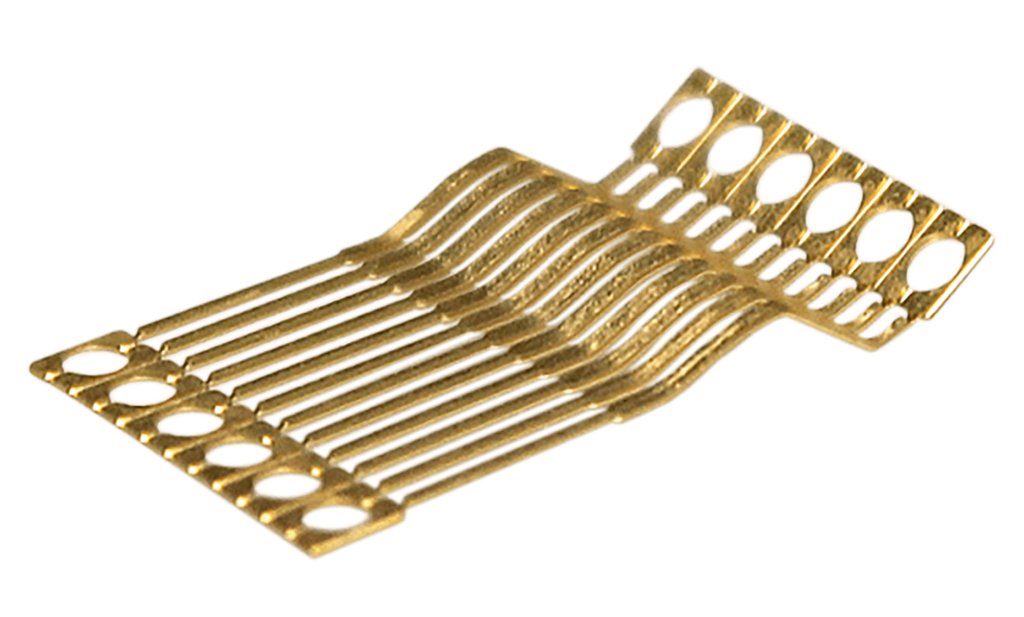

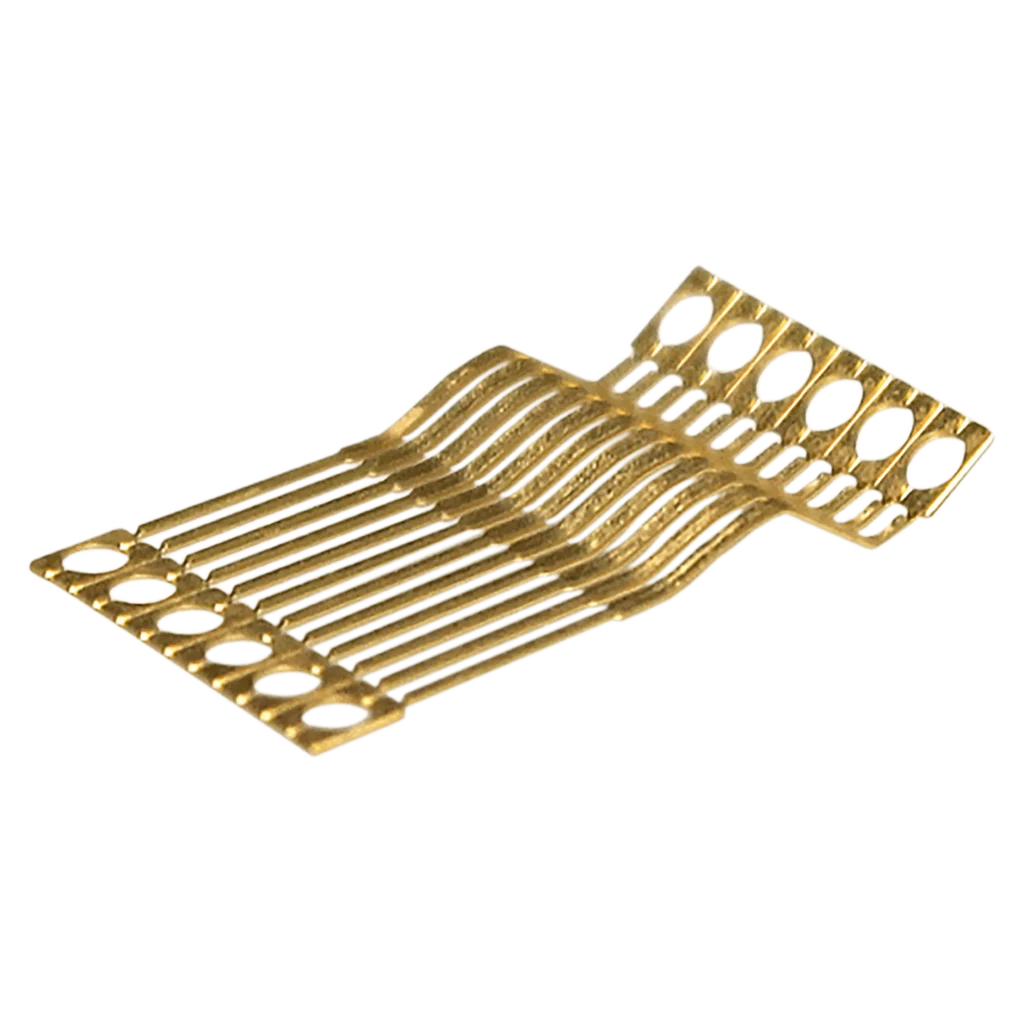

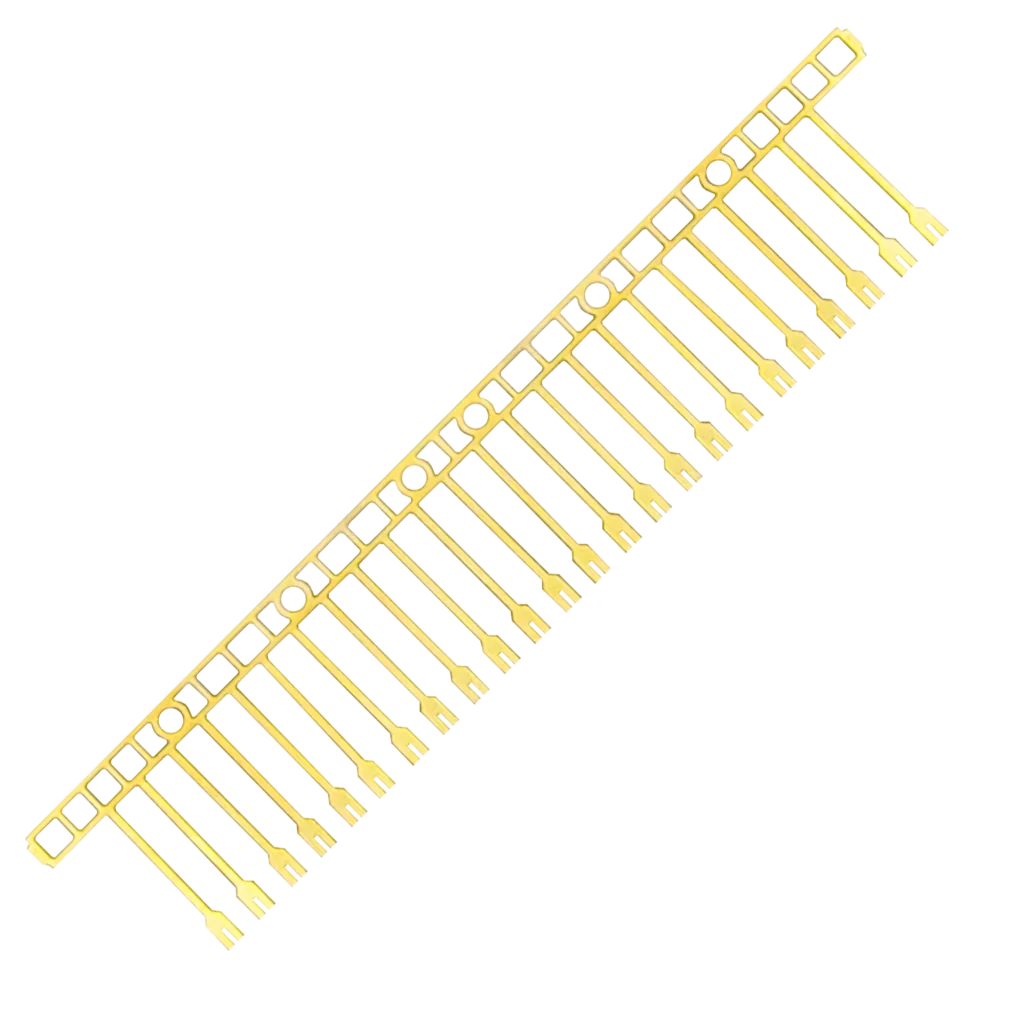

Photochemical etching, also known as precision chemical machining, chemical blanking, or acid etching, is an exact subtractive manufacturing process where chemical etchants selectively remove metal from a thin sheet to create intricate shapes, patterns, and features. Unlike traditional methods, photochemical machining does not involve mechanical force or direct contact with the sheet of metal, minimizing the risk of distortion, burrs, or stress-induced deformation

The benefits of photochemically etching contact strips include fabricating precise parts with intricate geometries and accurate patterns.

Here are additional benefits of titanium photochemical etching:

With a history of engineering excellence, PEI is among the top companies providing photochemically etched metal parts and components for various critical industries.

With ISO-9001:2008 and AS9100 certifications, PEI was also granted certification under the International Traffic in Arms Regulation (ITAR) in 2010, enabling it to provide weapon system components and accessories in compliance with the Code of Federal Regulations implemented by the U.S. Department of State.

Our rigorous inspection processes and testing procedures ensure that every product we produce meets stringent accuracy, reliability, and performance standards.