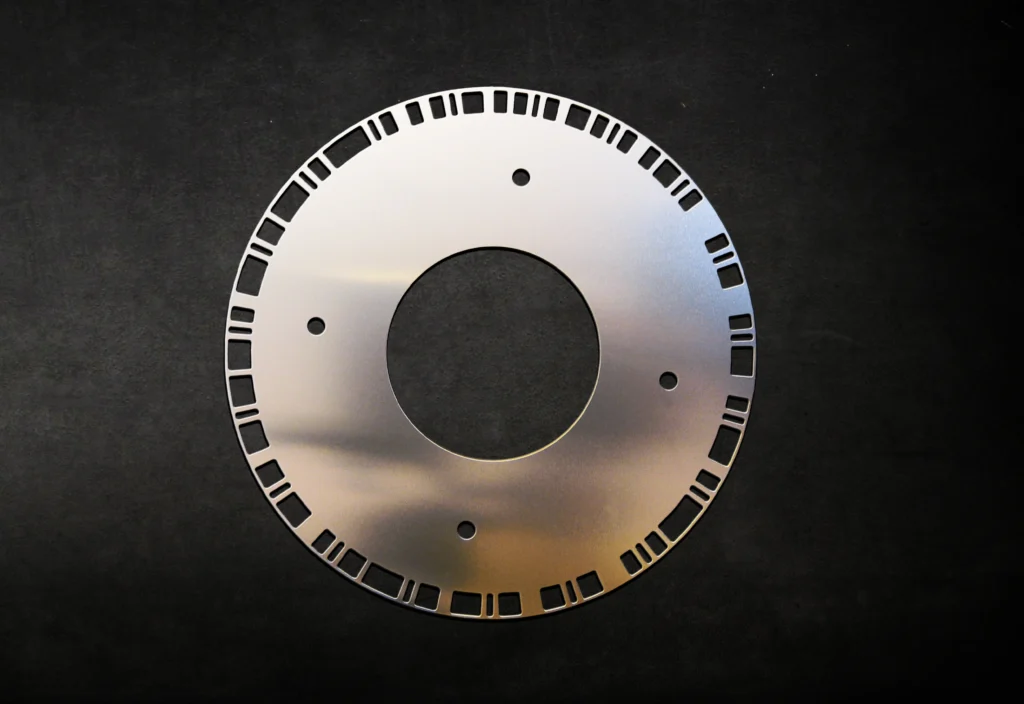

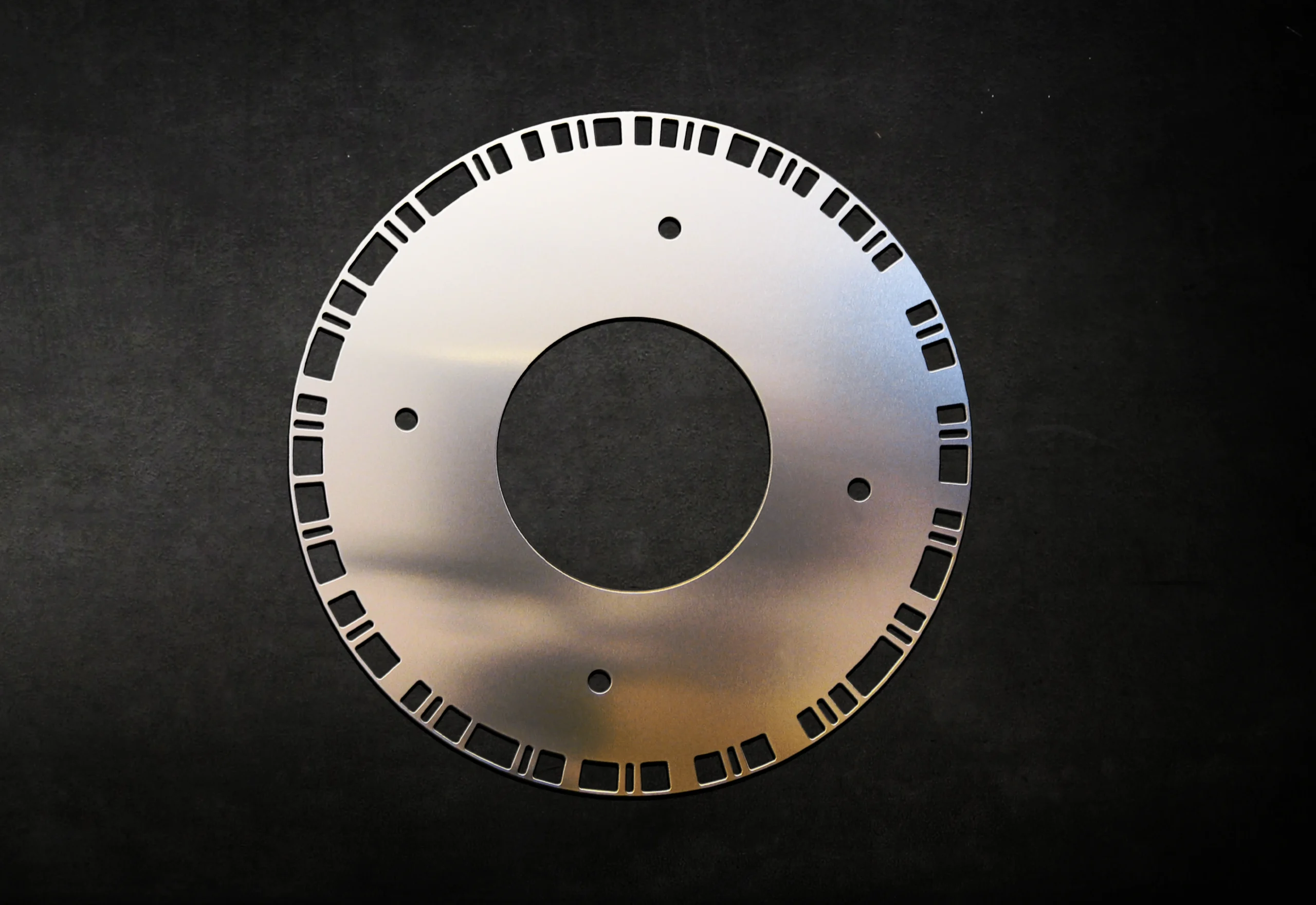

At the heart of the advancements in the automotive industry are the components that power electric motors, including stators and rotors. Stators work with the rotor to create the electromagnetic field that drives an electric motor. Their precision and quality are not just critical, but they are the key to unlocking the full potential of an electric motor, enhancing its performance and reliability.

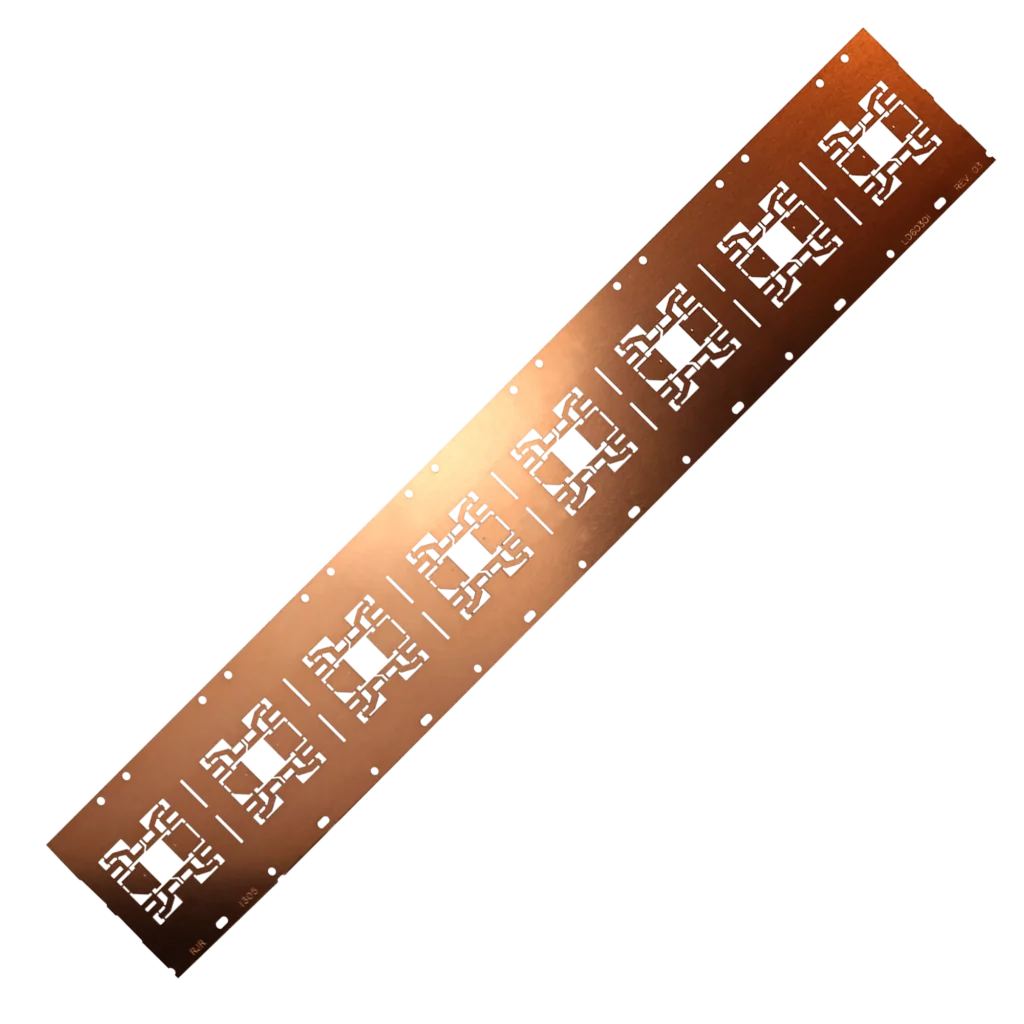

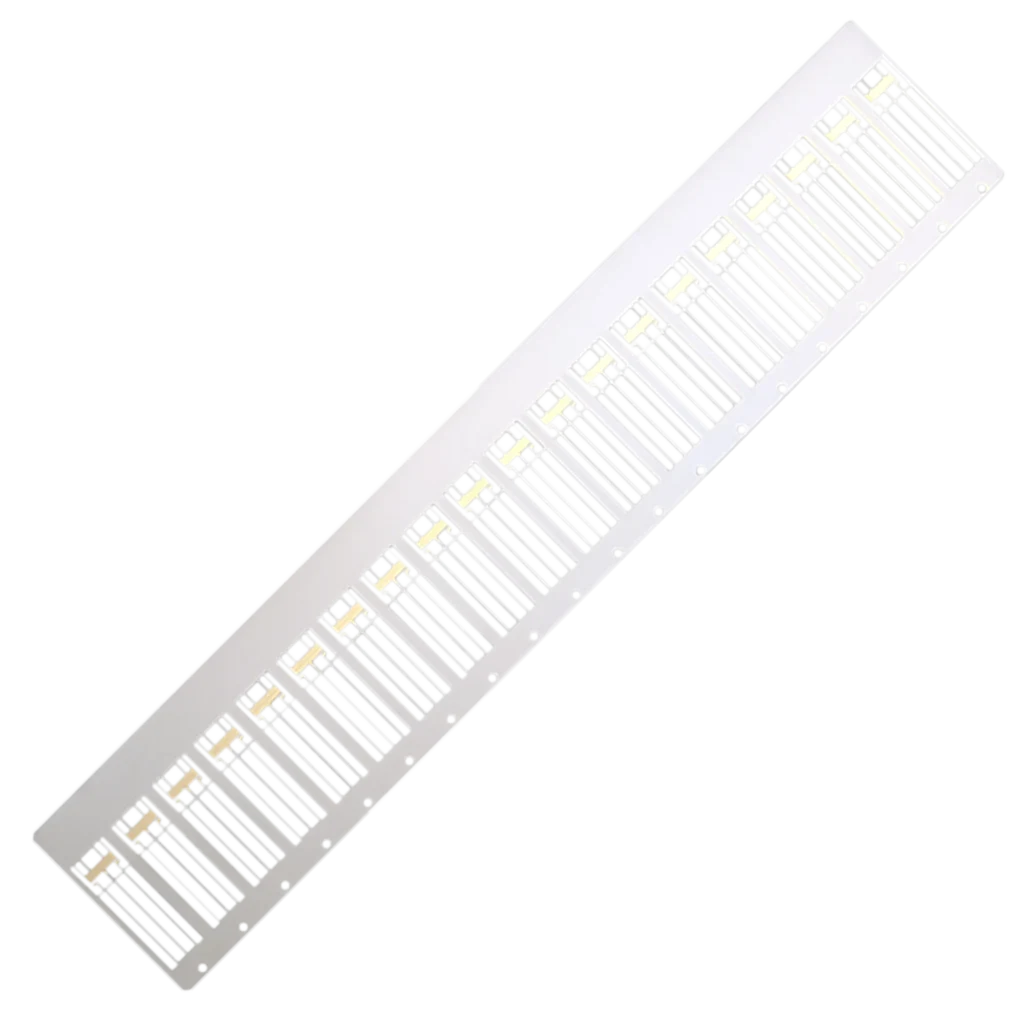

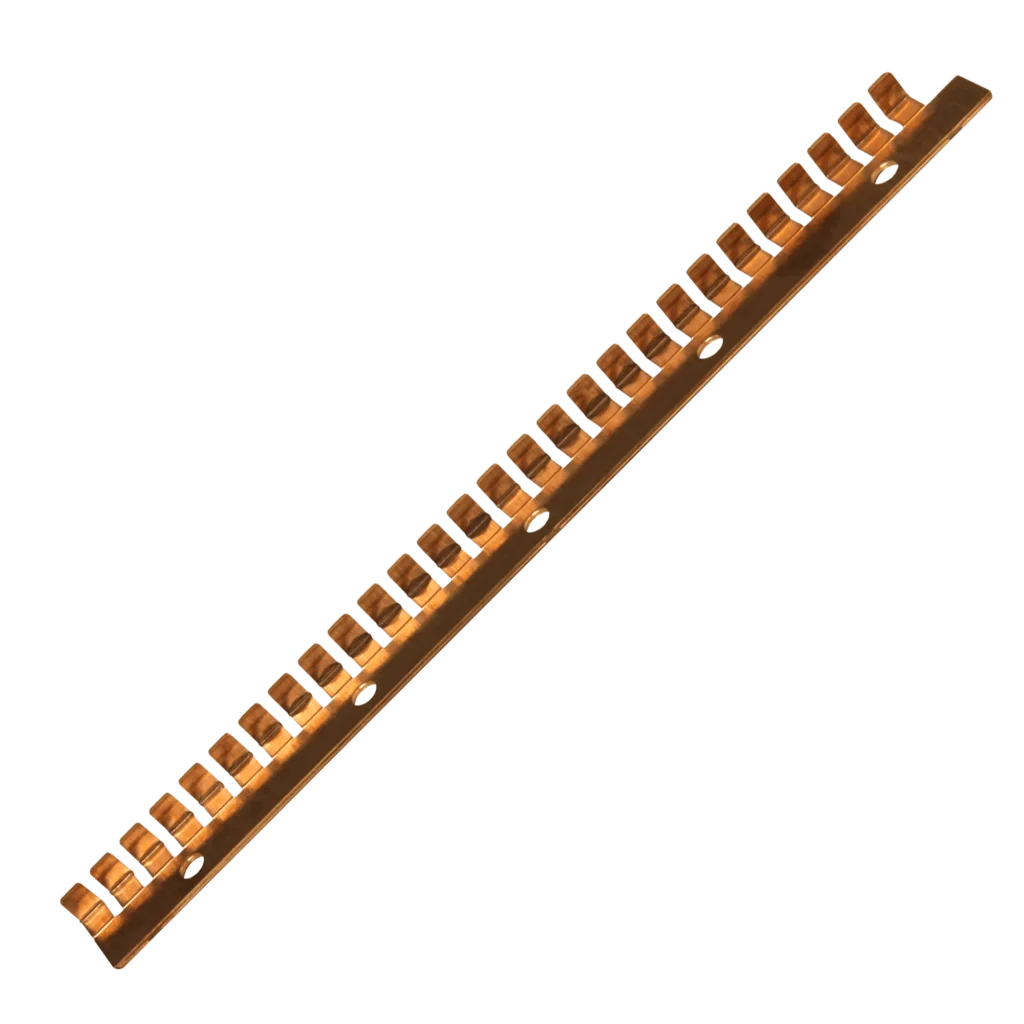

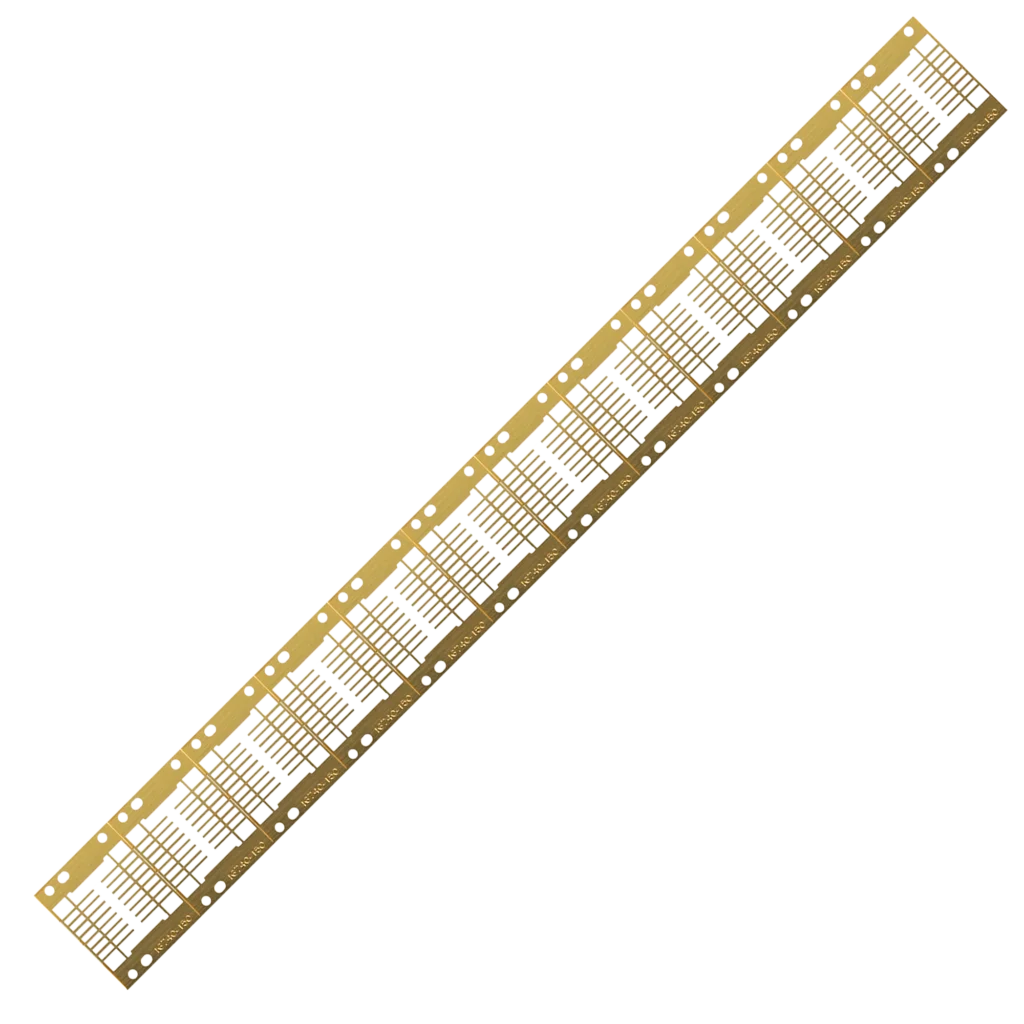

PEI’s precision chemical machining techniques ensure high-quality stators and rotors (also known as laminations) with smooth operation, long-term durability, and optimal energy conversion. These components meet the automotive industry’s strictest requirements and provide optimized parts for peak efficiency.

Our robust manufacturing capabilities support the precision required and the high production volumes demanded by the industry, ensuring consistent quality at scale.

A stator is a fixed part in an electric motor that provides a magnetic field driving the rotating armature. The stator is essential to the conversion of electrical energy to mechanical energy.

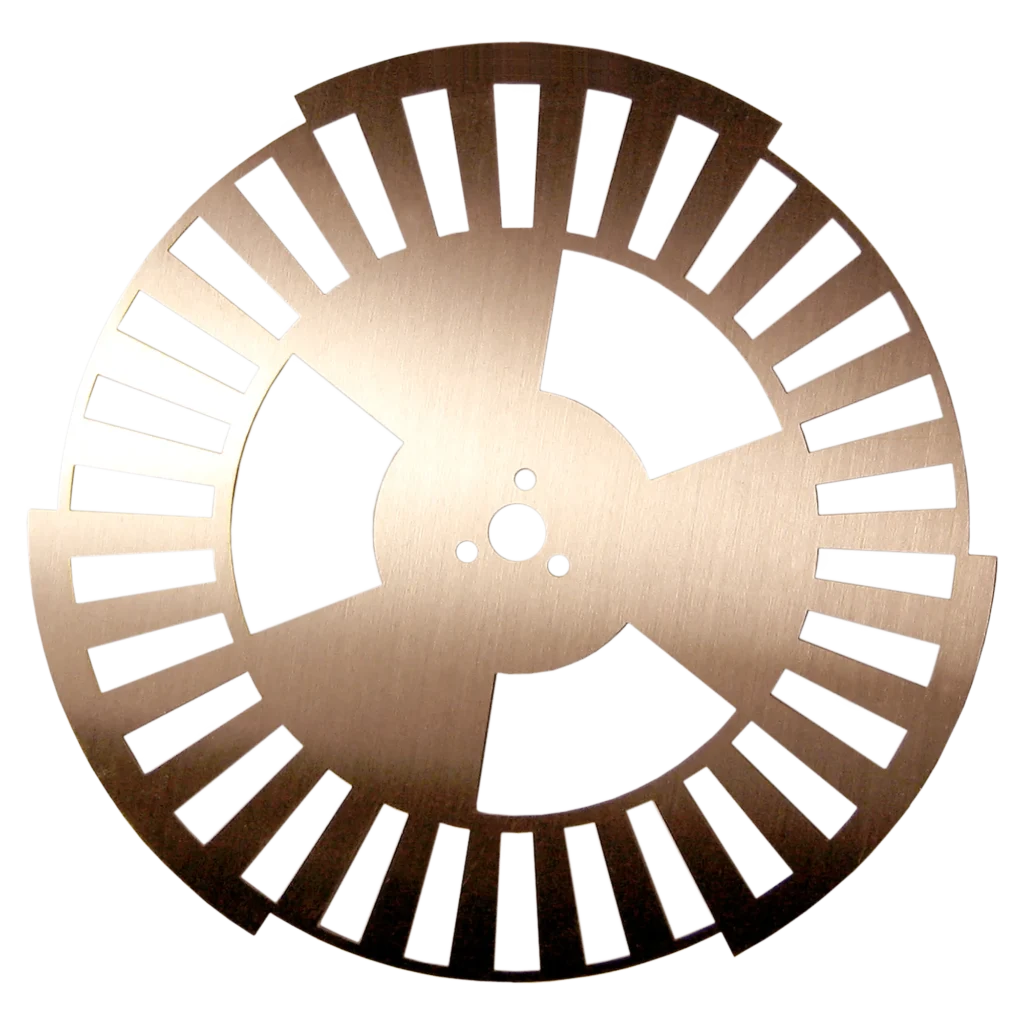

A rotor is the rotating component of an electric motor that takes the interaction between electromagnetic windings and magnetic fields and turns them into torque.

PEI operators understand the intricate nature of stators and rotors and how their integration is essential to the operation of electric motors. Our engineers, manufacturers, and quality assurance professionals deliver the parts necessary for durable and reliable performance.

PEI’s decades of experience producing precise parts used in stators and rotors means we are experts in using a variety of metals, including:

Steel

Aluminum

Copper

Brass

PEI operators produce precision stator and rotor parts used by industry-leading companies serving the automotive and transportation sectors.

Stators and rotors are essential to producing activity and torque in electric motors.

Photochemical etching, also known as precision chemical machining, chemical blanking, or acid etching, is an exact subtractive manufacturing process where chemical etchants selectively remove metal from a thin sheet to create intricate shapes, patterns, and features. Unlike traditional methods, photochemical machining does not involve mechanical force or direct contact with the sheet of metal, minimizing the risk of distortion, burrs, or stress-induced deformation.

The benefits of photochemically etching stators and rotors parts include fabricating precise parts with intricate geometries and accurate patterns.

Here are additional benefits of titanium photochemical etching:

With a history of engineering excellence, PEI is among the top companies providing photochemically etched metal parts and components for various critical industries.

With ISO-9001:2008 and AS9100 certifications, PEI was also granted certification under the International Traffic in Arms Regulation (ITAR) in 2010, enabling it to provide weapon system components and accessories in compliance with the Code of Federal Regulations implemented by the U.S. Department of State.

Our rigorous inspection processes and testing procedures ensure that every product we produce meets stringent accuracy, reliability, and performance standards.