Coatings play an essential role in maintaining the integrity of precision metal parts produced via photochemical etching, protecting parts and components from corrosion, wear, and environmental hazards. Finishing, plating, coating, or painting metal parts also serves an aesthetic and antibiotic purpose.

Choosing the proper coating depends on the final usage of the part or component, and a trusted manufacturing partner can help understand the benefits and weaknesses of available solutions.

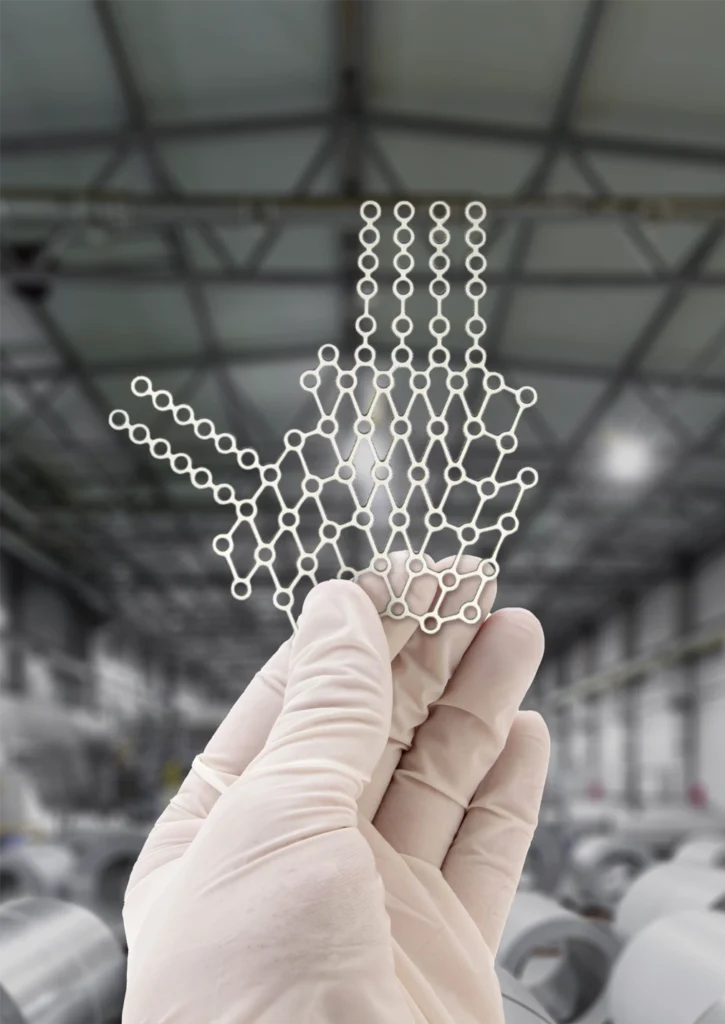

As a leader in delivering precision metal parts for the world’s most important industries with decades of experience, PEI features the expertise to help manufacture, inspect, finish, and deliver reliable and durable products.

Contact us today to discuss your project or ask us any questions about coatings and photochemical etching.

Selecting the appropriate coating materials and methods is pivotal in achieving high-quality, finely detailed components, with choices based on a number of factors, from their compatibility in final usage to environmental conditions.

Here are some common factors to consider:

Consider the environment the components will be in (temperature, humidity, UV exposure, and chemical contact)

Choose coatings that match the expected lifespan of the components to reduce waste.

Ensure coatings resist exposure to chemicals or corrosive substances.

Opt for environmentally friendly coatings to minimize harm to ecosystems.

Use low-VOC coatings to reduce air pollution and indoor air quality issues.

Prefer eco-friendly methods like powder coating, which is more efficient.

Minimize waste generation during application and disposal.

Choose water-based coatings to reduce environmental impact.

Adhere to local regulations regarding coatings and the environment.

Assess the full environmental impact from production to disposal.

Use coatings with renewable or recycled materials when possible.

Consider the environmental impact of coating packaging and shipping.

Select coatings that are easy to repair or recoat to extend component lifespans.

Match the coating to the component material.

Properly prepare the surface for adhesion.

Determine the desired thickness.

Choose the right method for the component's size and shape.

Ensure compatibility and strong adhesion.

Account for temperature, humidity, and air quality.

Implement checks for defects.

Ensure proper equipment calibration.

Follow safety protocols.

Optimize productivity without compromising quality.

Plan for waste disposal or recycling.

Train skilled personnel for precise application.

Comply with regulations.

Keep records for tracking and troubleshooting.

Choosing the right coating will enhance metal parts’ performance, durability, and reliability with complex geometries and high tolerances.

Here are some common coatings and where they might be found:

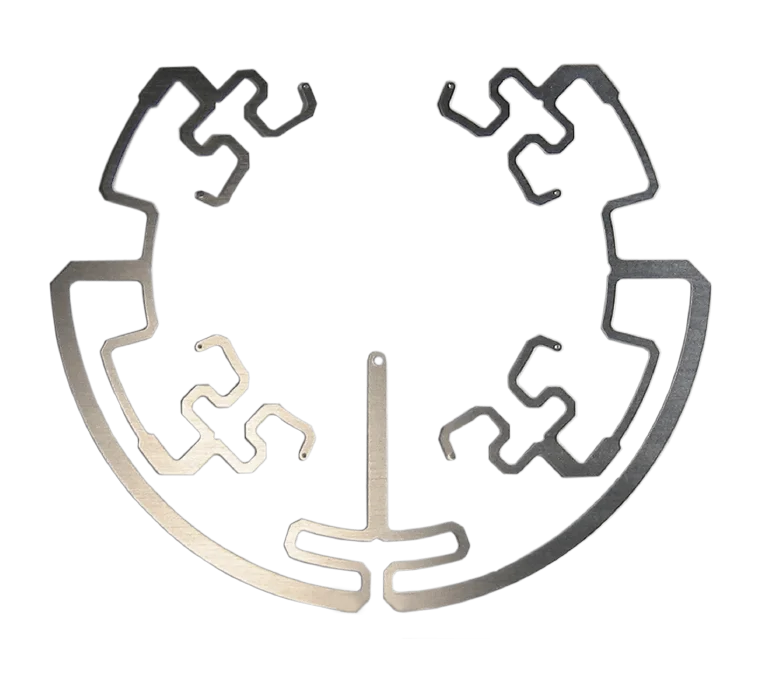

A chemical conversion coating applied during the photochemical etching process primarily used on ferrous metals like steel and stainless steel. This coating enhances corrosion and rust resistance and provides a black or dark gray appearance. Manufacturers serving aerospace, defense, industrial and automotive sectors call for Black Oxide Coating

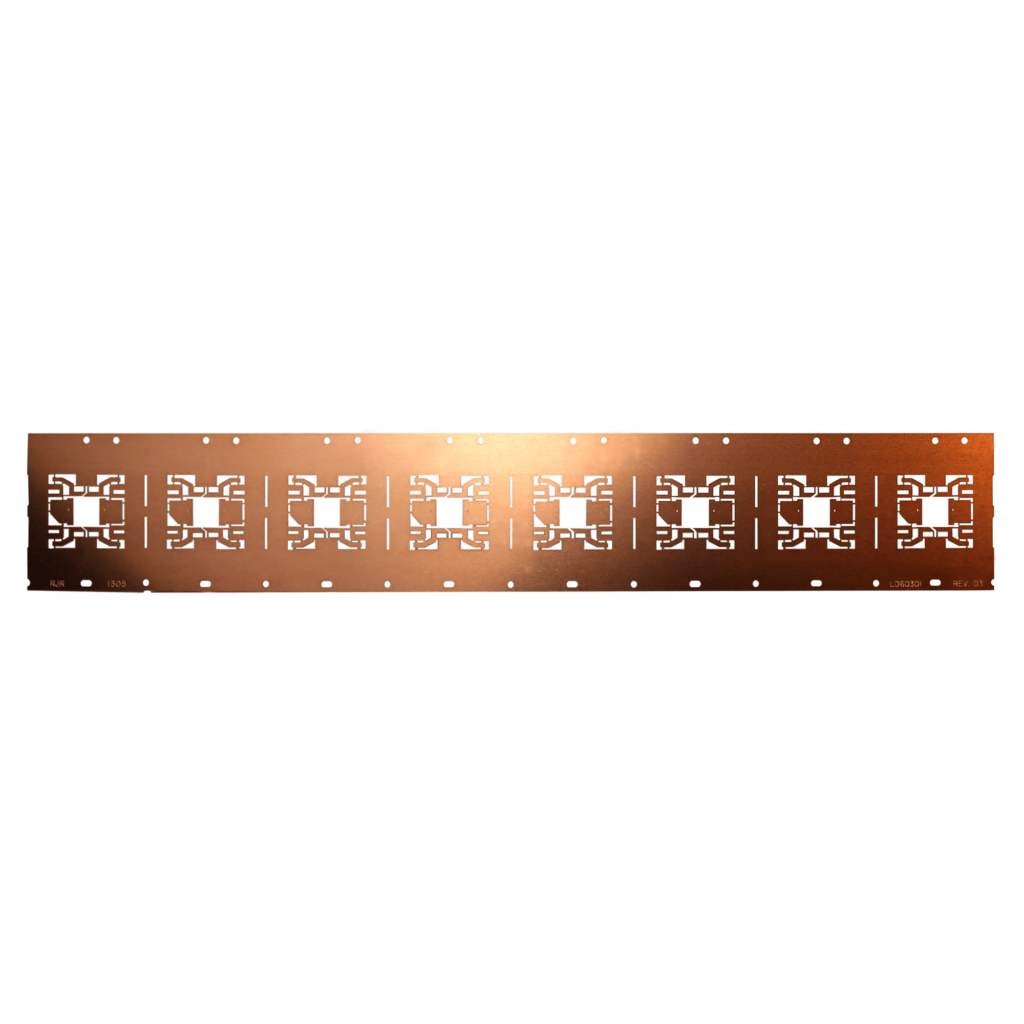

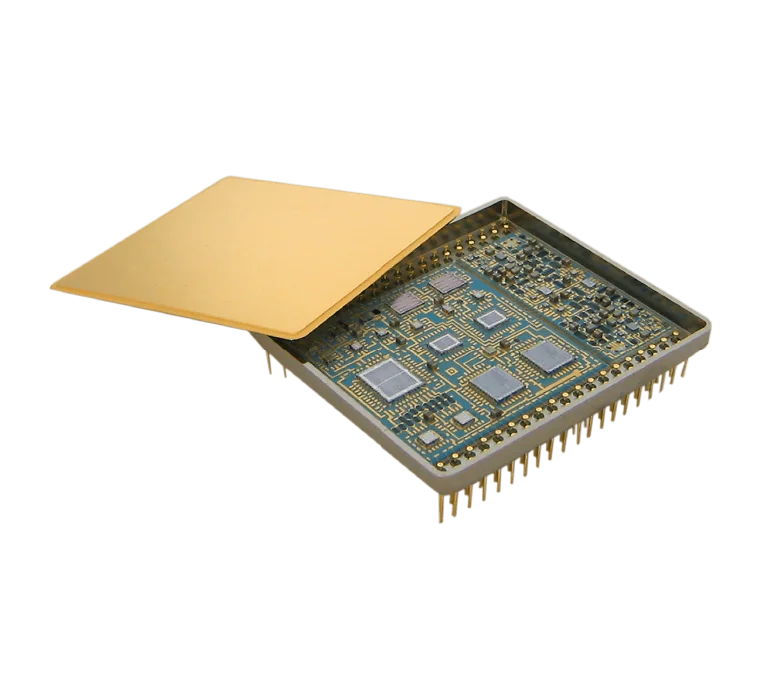

An electrochemical process where a thin layer of copper is deposited onto the surface of another metal or substrate. Copper plating enhances electrical conductivity, improves corrosion resistance, and provides an attractive copper appearance. Common applications of copper plating include electrical connectors, printed circuit boards (PCBs), decorative items, and components in the electronics and telecommunications industries. Copper plating is also frequently used as an intermediate layer before applying additional plating or finishing processes, such as tin, nickel or chrome plating, to achieve desired performance and aesthetics.

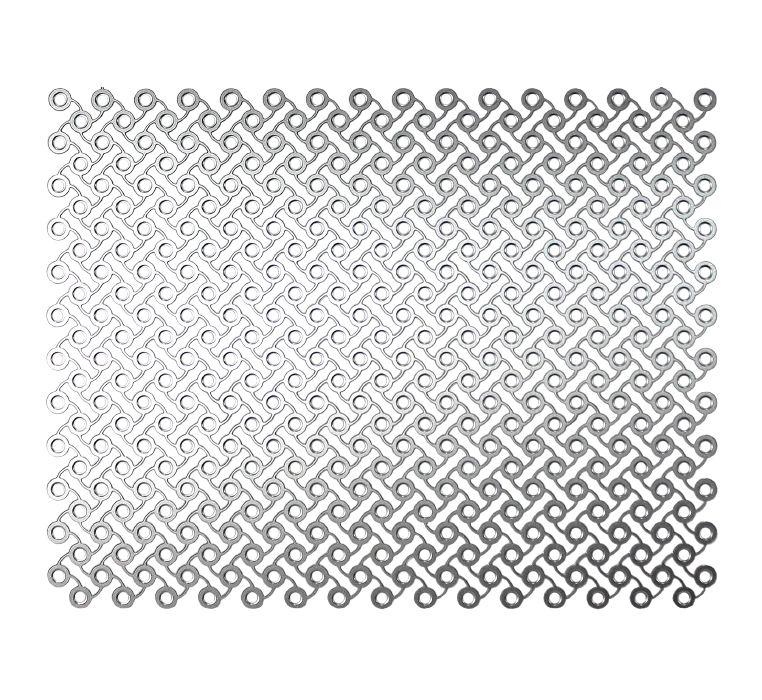

A process where a controlled electrical current is passed through the metal object while it is immersed in an electrolyte solution, selectively removing a thin layer of material from the surface, effectively smoothing out roughness, removing burrs, and eliminating micro-scale imperfections. There are several benefits to electropolishing, including enhanced corrosion resistance, improved cleanliness, and a highly reflective, smooth, and clean surface finish. Manufacturers serving the medical, aerospace, pharmaceutical, and food processing industries use electropolishing.

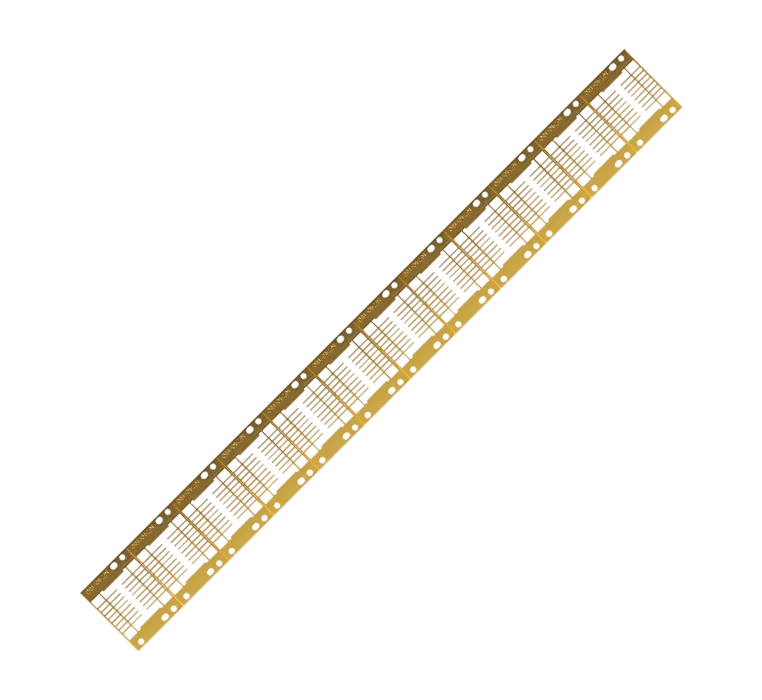

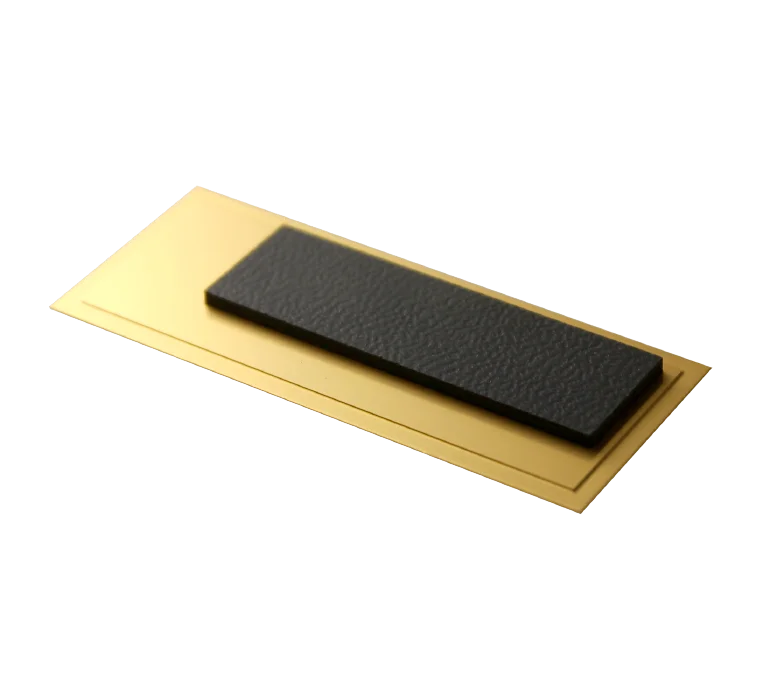

A thin layer of gold is electrochemically deposited onto the surface of a metal part or component. Gold plating enhances electrical conductivity and provides corrosion resistance. Gold plating is popular in industries such as electronics and aerospace.

An electrochemical process where a thin layer of nickel is deposited onto the surface of a substrate, often made of metal. Nickel plating helps with corrosion resistance and wear resistance, providing a barrier against oxidation while strengthening the substrate. Nickel plating is found on automotive parts, plumbing fixtures, electronics components, and industrial machinery, where both protection against corrosion and an attractive finish are essential. Nickel plating can also serve as a base layer for subsequent coatings, such as chrome plating, to further enhance performance and appearance.

A widely used finishing technique that enhances the appearance of a part or component, protects surfaces from environmental factors like corrosion and UV radiation, and provides insulation or fire resistance. Different types of paint, such as water-based, oil-based, or specialty coatings, are chosen based on the specific application requirements.

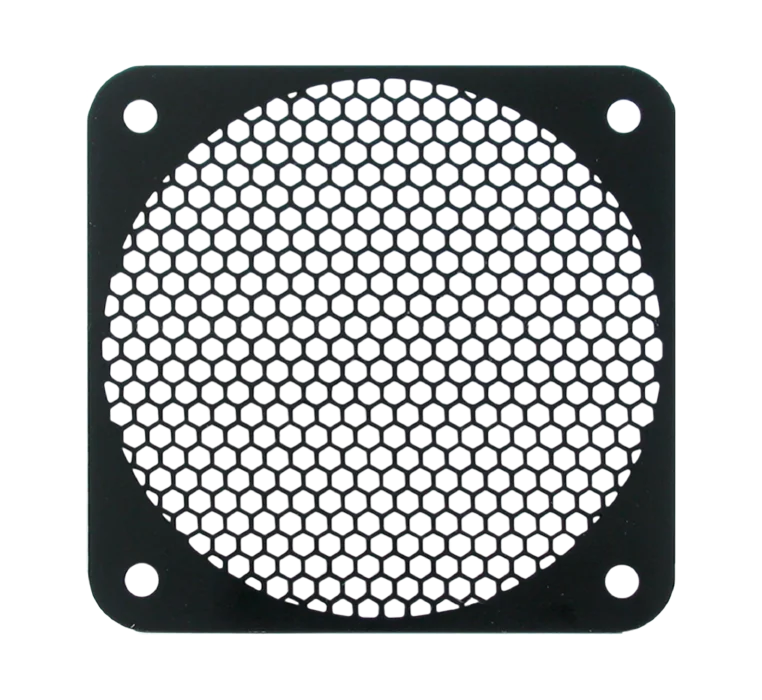

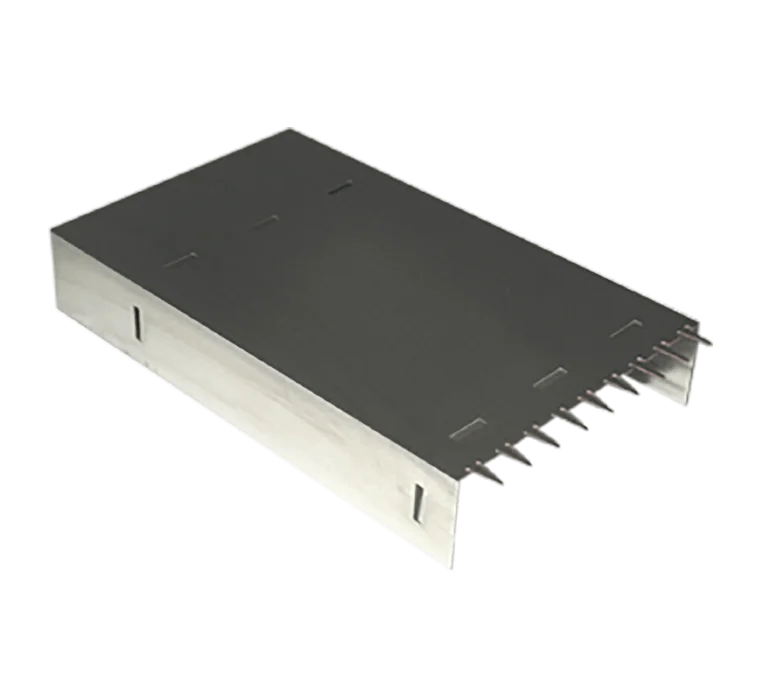

A dry finishing process used to apply a durable and protective layer to the surface of various objects. The steps to powder coating include electrostatically charging powdered pigment particles, which are then sprayed onto a grounded object. The charged particles adhere to the object’s surface, creating a uniform and highly adhesive coating. After application, the coated object is heated, causing the powder to melt, flow, and cure, resulting in a hard, smooth, and resilient finish. Powder coating offers numerous advantages, including excellent resistance to corrosion, chemicals, and UV radiation, as well as a wide range of color options and a more environmentally friendly process compared to traditional liquid coatings. It is commonly used in aerospace, defense, medical, industrial, and automotive industries.

An electrochemical process that involves depositing a thin layer of silver onto the surface of a substrate, often another metal. Silver plating improves electrical conductivity and provides corrosion resistance. Electronics and telecommunications manufacturers call for silver plating for connectors and conductive components due to its excellent electrical conductivity. Additionally, silver’s natural antimicrobial properties make it suitable for applications in healthcare, such as coating medical instruments and equipment.

An electrochemical process that involves depositing a thin layer of tin onto the surface of a substrate, which is often made of a different metal, such as copper or steel. Its benefits include corrosion resistance and solderability, which is necessarily in the electronics industry where it’s essential to create reliable solder joints. Common applications of tin plating include electrical connectors, printed circuit boards (PCBs), food and beverage containers (tin cans), and various consumer products. It is also used to protect metals from corrosion, particularly in harsh environments.

Most of the precise metal parts and components fabricated are coated in some way, whether it’s to improve electrical conductivity, appearance, or corrosion resistance.

Coatings play a crucial role in delivering precise parts and components that are reliable and durable.

Our expert manufacturing and finishing teams have decades of experience applying various coatings and finishes depending on the part’s specifications and usage.

Contact us today to discuss your project or ask us any questions about coatings and photochemical etching.