The semiconductor industry demands precision, reliability, and durability in all the thin metal parts and components used in its technology. So, it’s no surprise that industry leaders tap manufacturing partners that can deliver exactly what they need at the stringent standards they set.

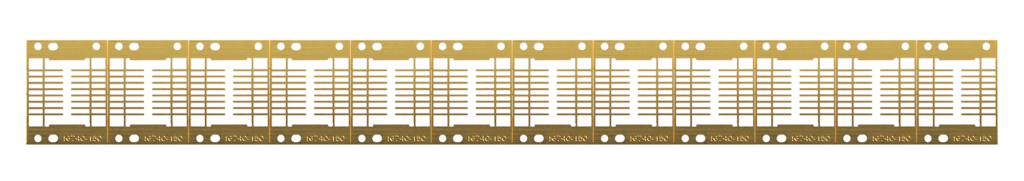

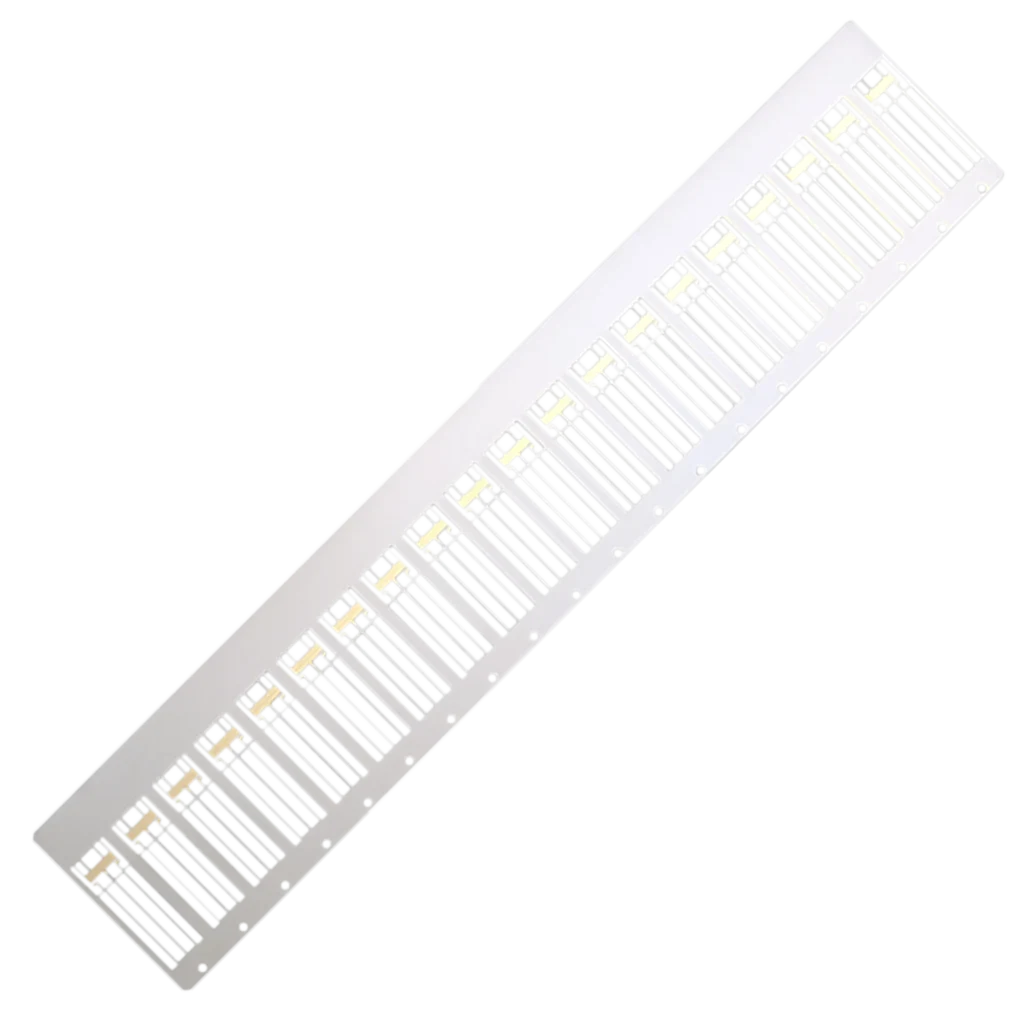

PEI knows this because PEI is a long time solutions provider to technology companies around the world. Our engineers, operators, and quality assurance professionals are experts at delivering lead frames used to support and connect integrated circuits found in assorted technology applications.

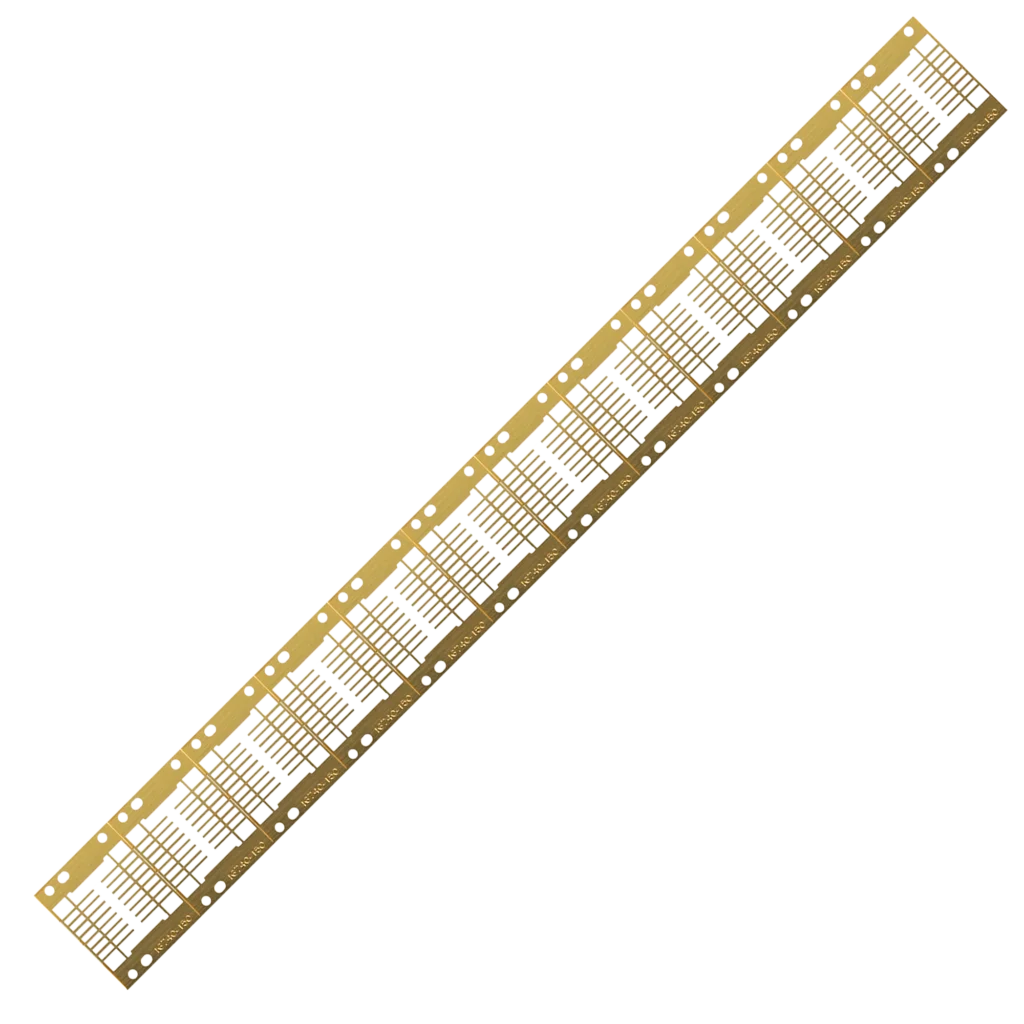

PEI leverages decades of experience and expertise in photochemical etching to fabricate lead frames that are relied on across several industries.

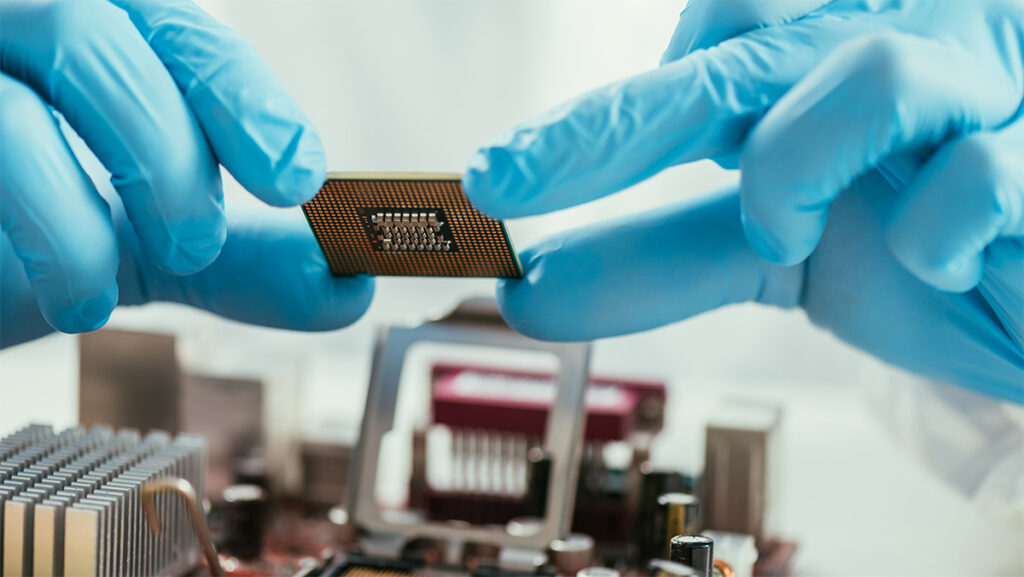

Lead frames are essential components that bridge the gap between semiconductor chips and external circuitry. Our high-quality lead frames are meticulously engineered, providing reliable electrical connections between semiconductor chips and external circuitry.

They maintain their integrity and performance even under extreme conditions — delivering the high accuracy and consistency needed for cutting-edge technological advancements.

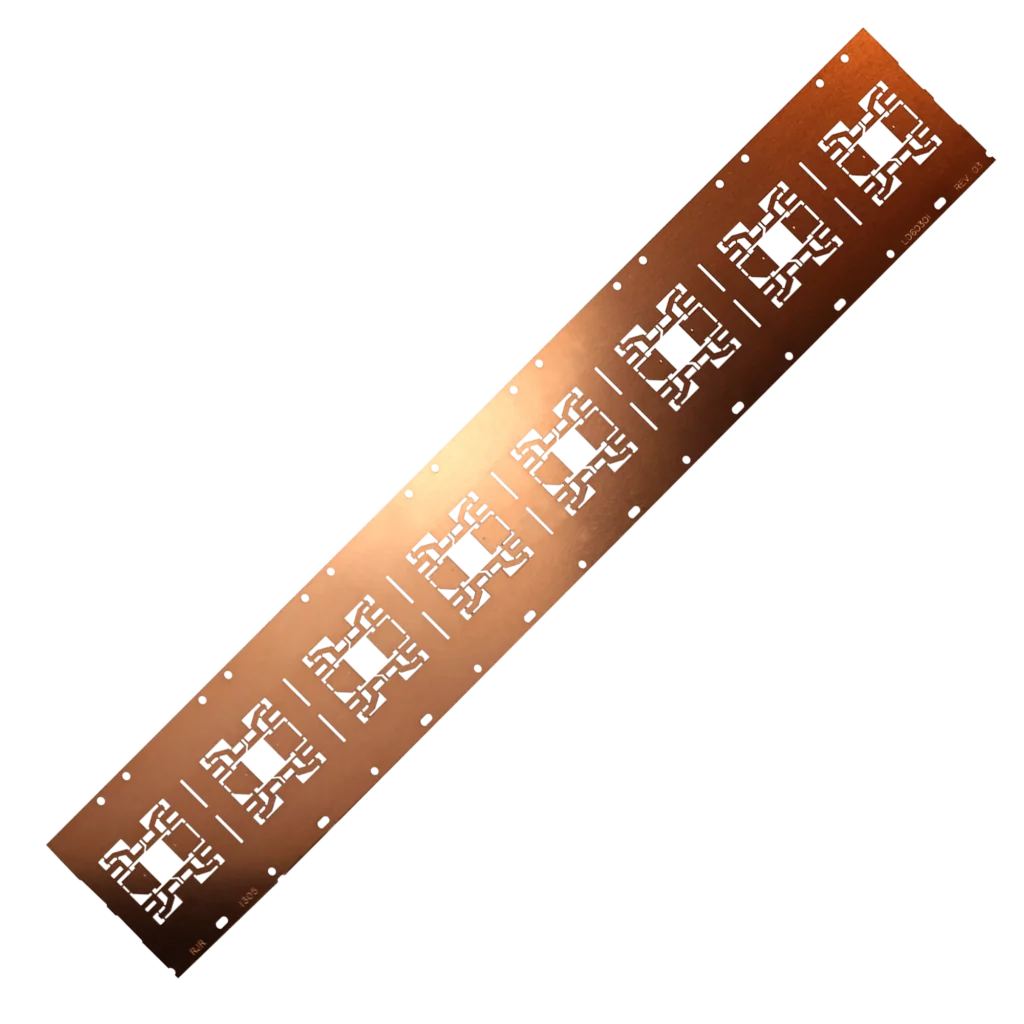

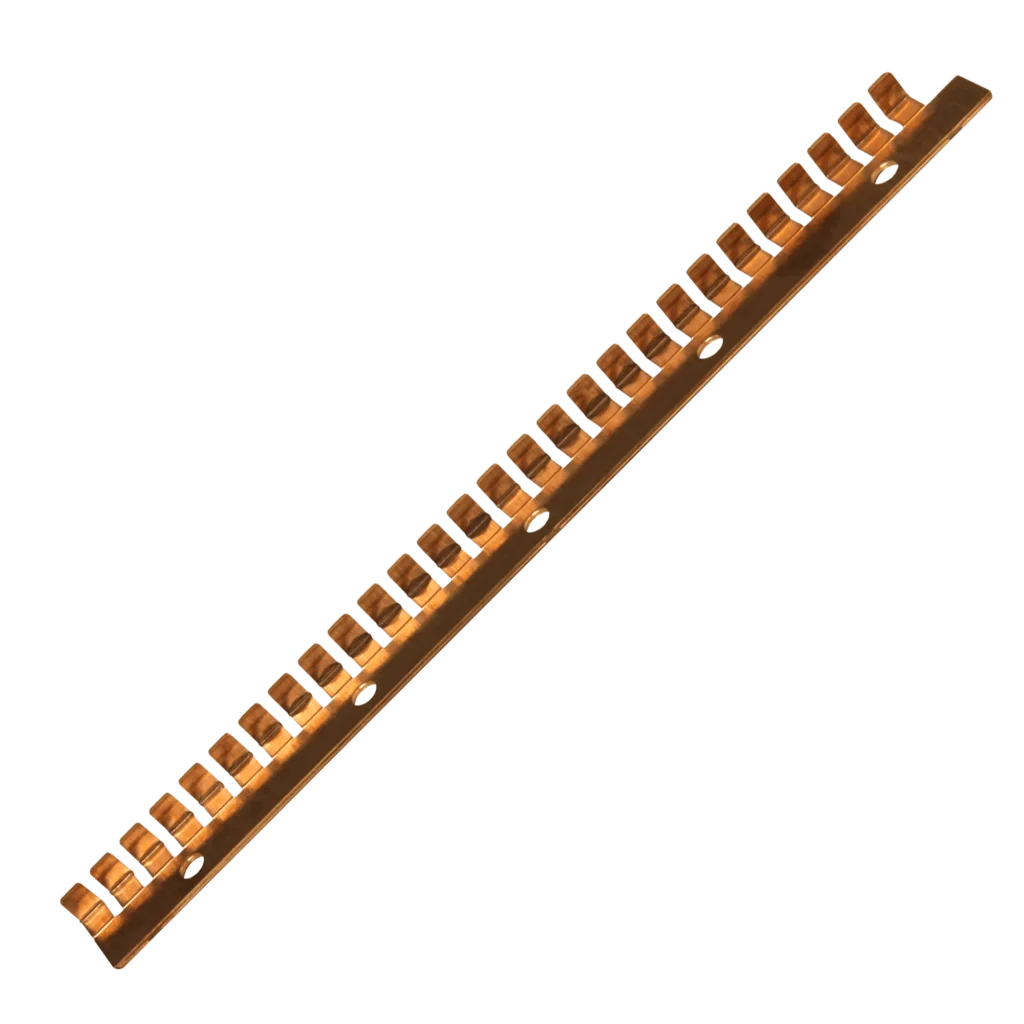

While several factors go into choosing what metals are best for lead frames, many engineers call for copper and copper alloys based on their electrical and thermal conductivity.

PEI has decades of experience fabricating lead frames from copper and these materials:

Iron-nickel alloys

Phosphor Bronze

Aluminum

For more than 50 years, PEI has supplied lead frames to leading manufacturers in the semiconductor and technology industries. Our lead frames can also be found in these industries and applications:

Lead frames are used in medical devices, including implantable devices, diagnostic equipment, and patient monitoring systems. They provide precise and dependable components for life-saving technology.

Lead frames are essential for various electronic devices, from consumer electronics to industrial equipment. They ensure strong power delivery, signal transmission, and heat dissipation for optimal performance.

Lead frames support the development of advanced telecommunication equipment. They are the foundation for efficient signal processing, power management, high-speed data transfer, and reliable connectivity.

Photochemical etching, also known as precision chemical machining, chemical blanking, or acid etching, is an exact subtractive manufacturing process where chemical etchants selectively remove metal from a thin sheet to create intricate shapes, patterns, and features. Unlike traditional methods, photochemical machining does not involve mechanical force or direct contact with the sheet of metal, minimizing the risk of distortion, burrs, or stress-induced deformation.

The benefits of photochemically etching lead frames include fabricating precise parts with intricate geometries and accurate patterns.

Here are additional benefits of titanium photochemical etching:

With a history of engineering excellence, PEI is among the top companies providing photochemically etched metal parts and components for various critical industries.

With ISO-9001:2008 and AS9100 certifications, PEI was also granted certification under the International Traffic in Arms Regulation (ITAR) in 2010, enabling it to provide weapon system components and accessories in compliance with the Code of Federal Regulations implemented by the U.S. Department of State.

Our rigorous inspection processes and testing procedures ensure that every product we produce meets stringent accuracy, reliability, and performance standards.