When it comes to precision metal shims, you need custom, high-quality solutions designed and manufactured to meet the exact tolerances and specifications of your project.

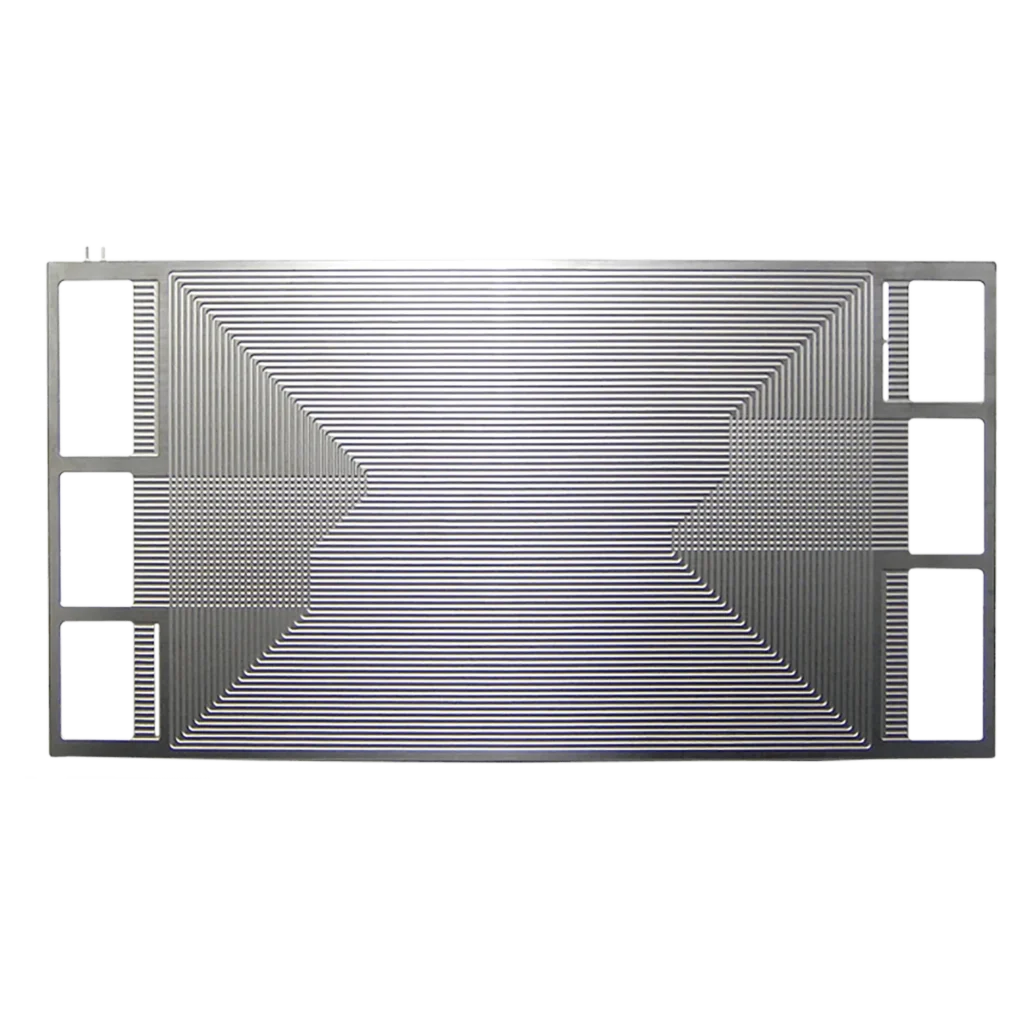

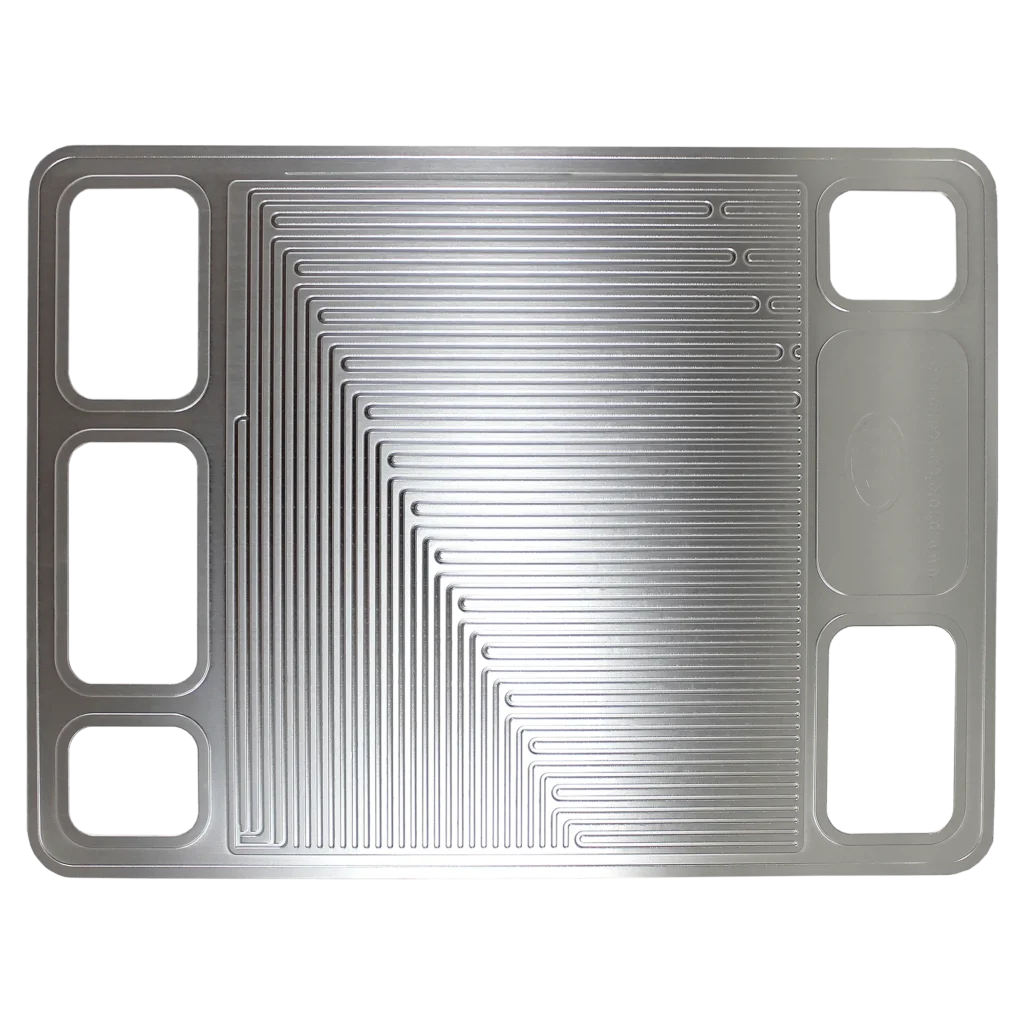

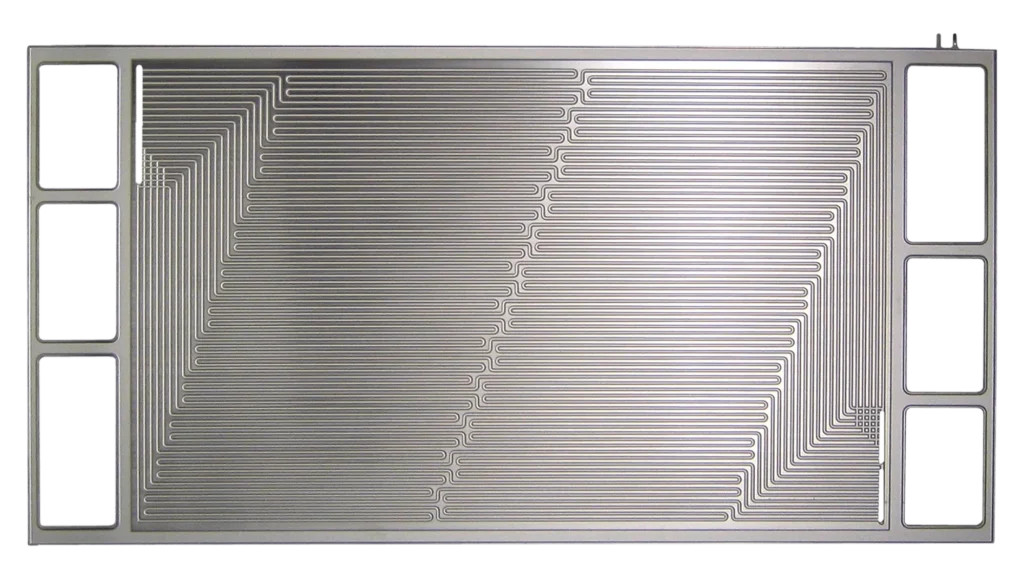

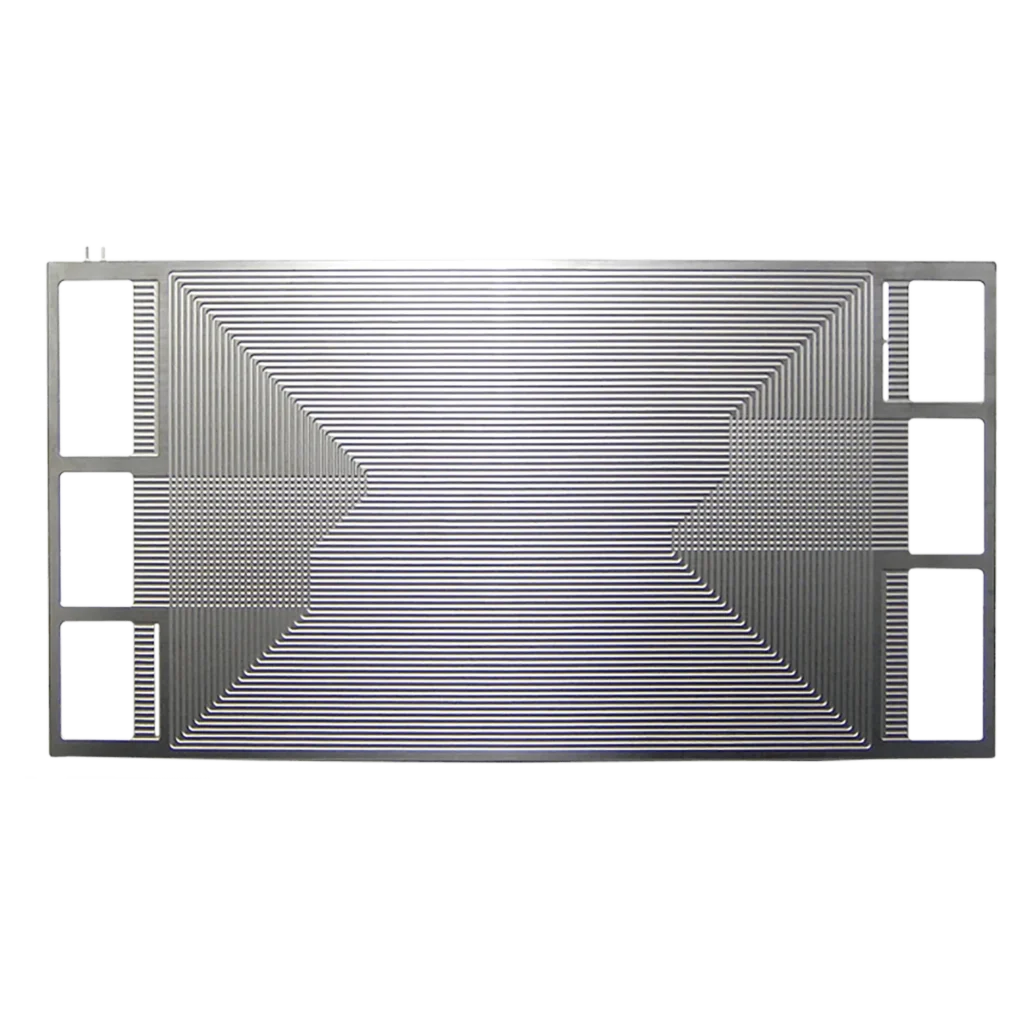

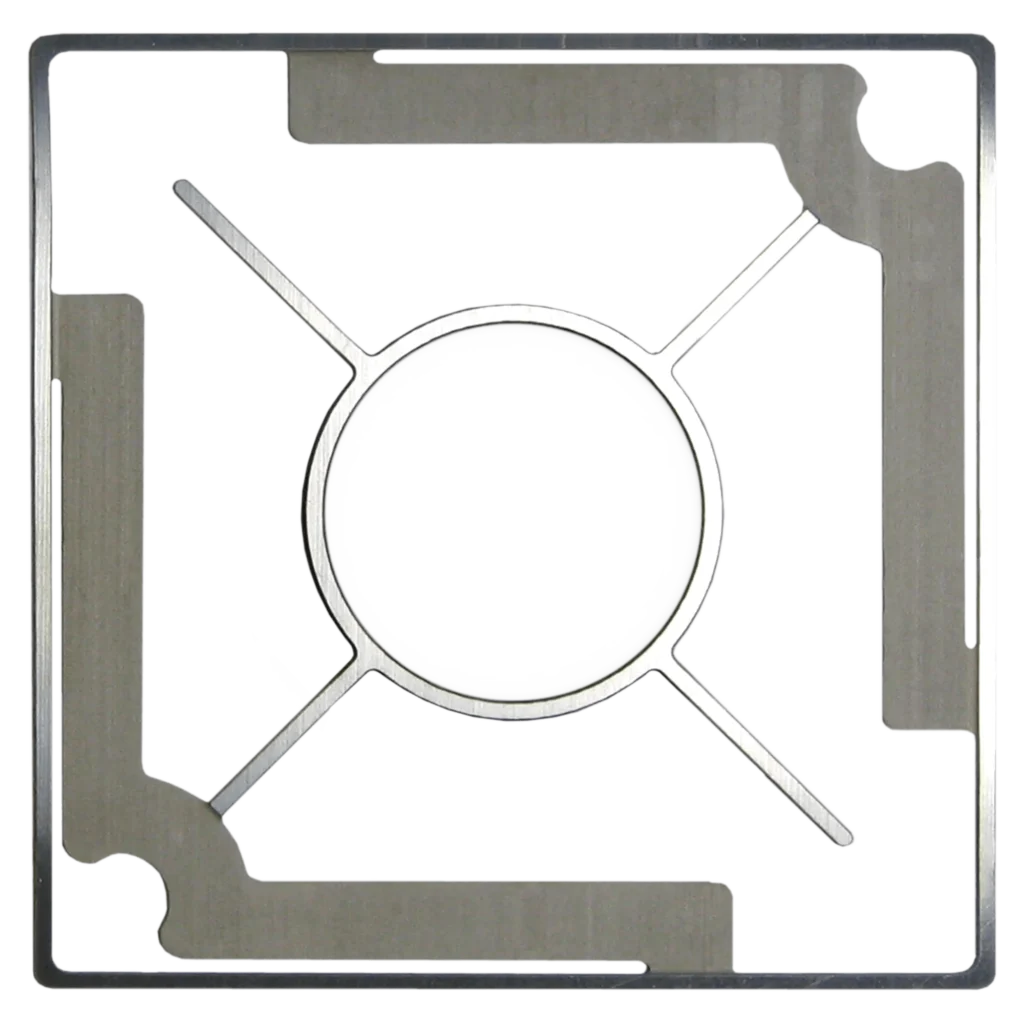

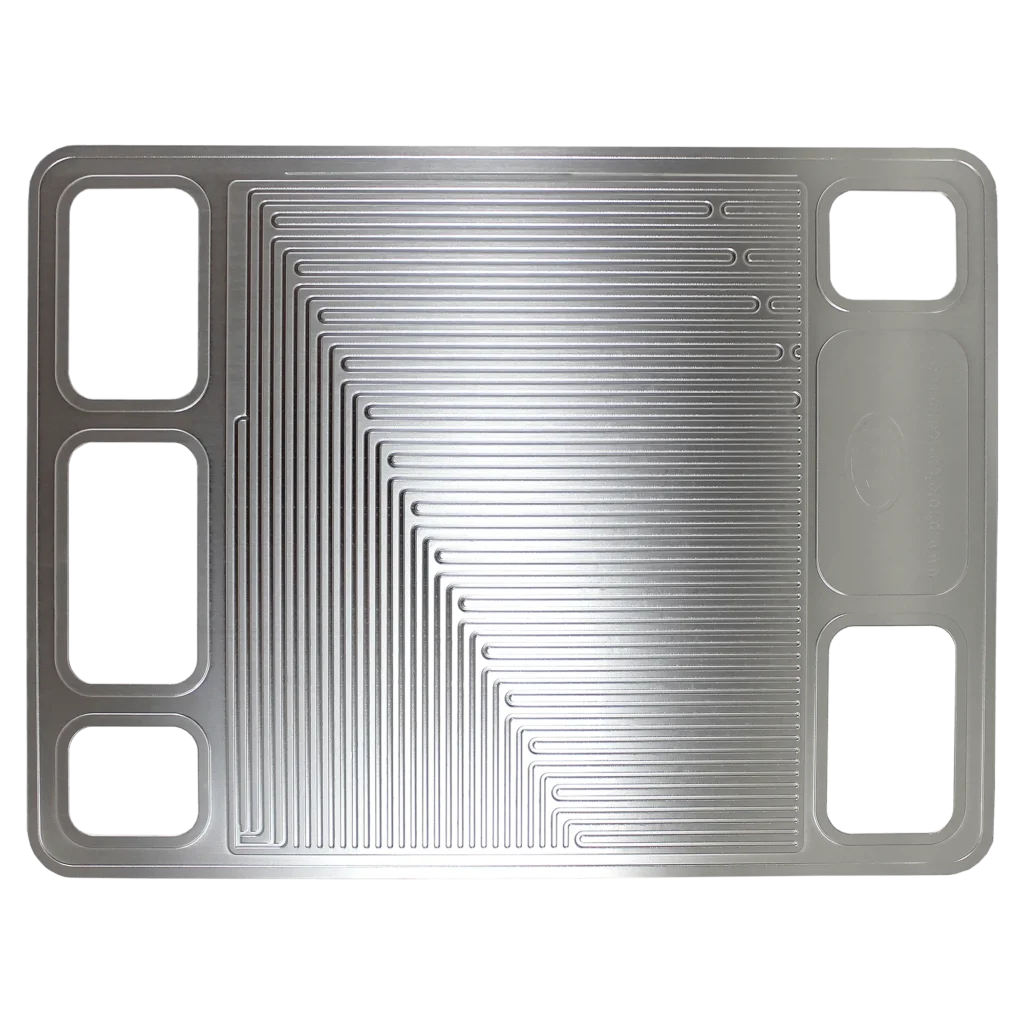

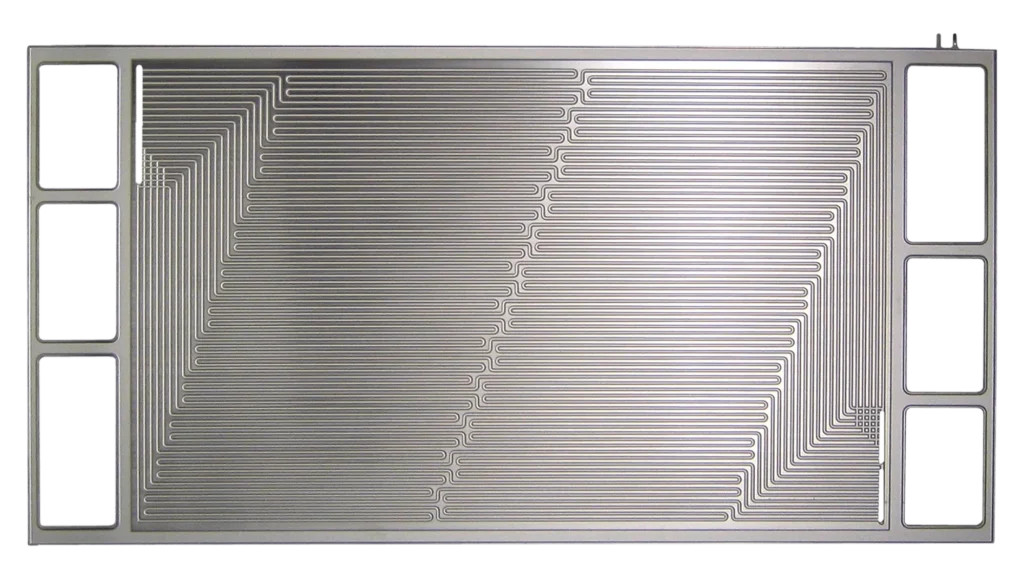

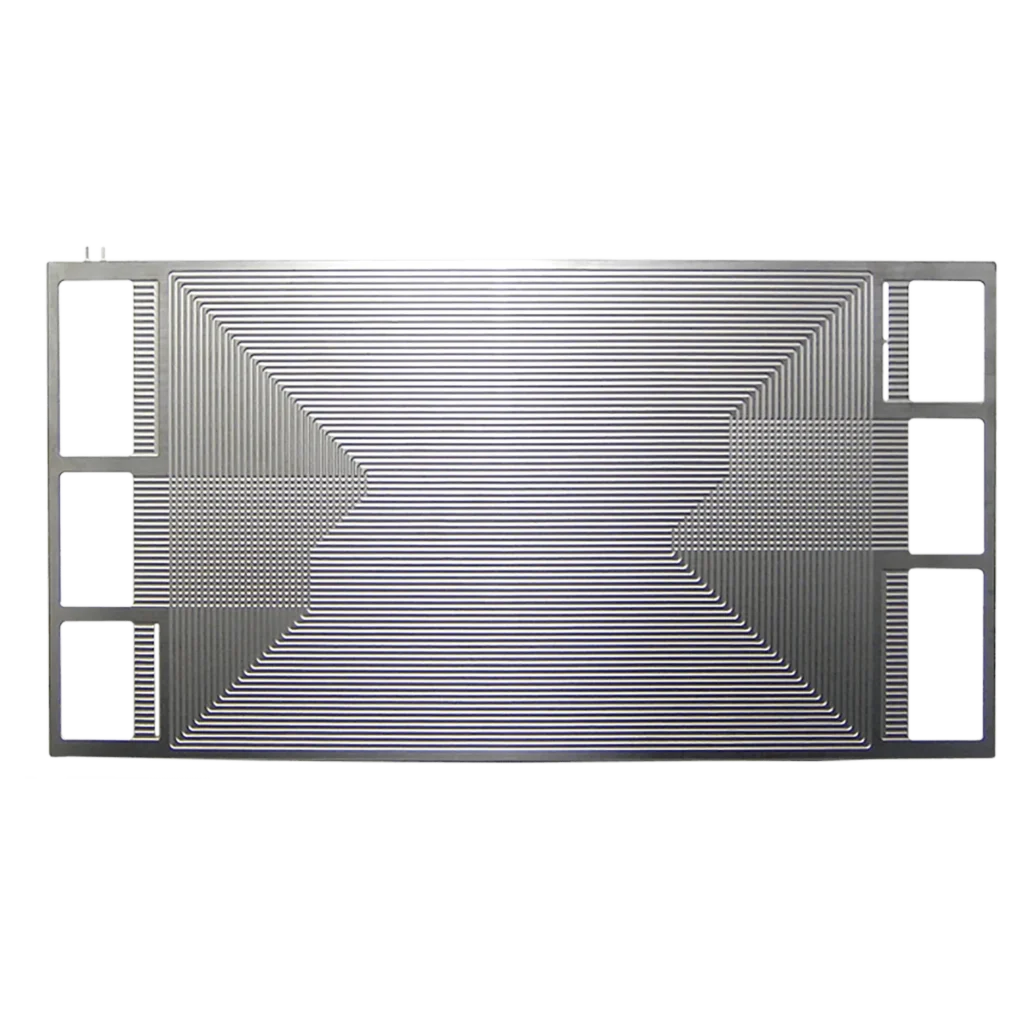

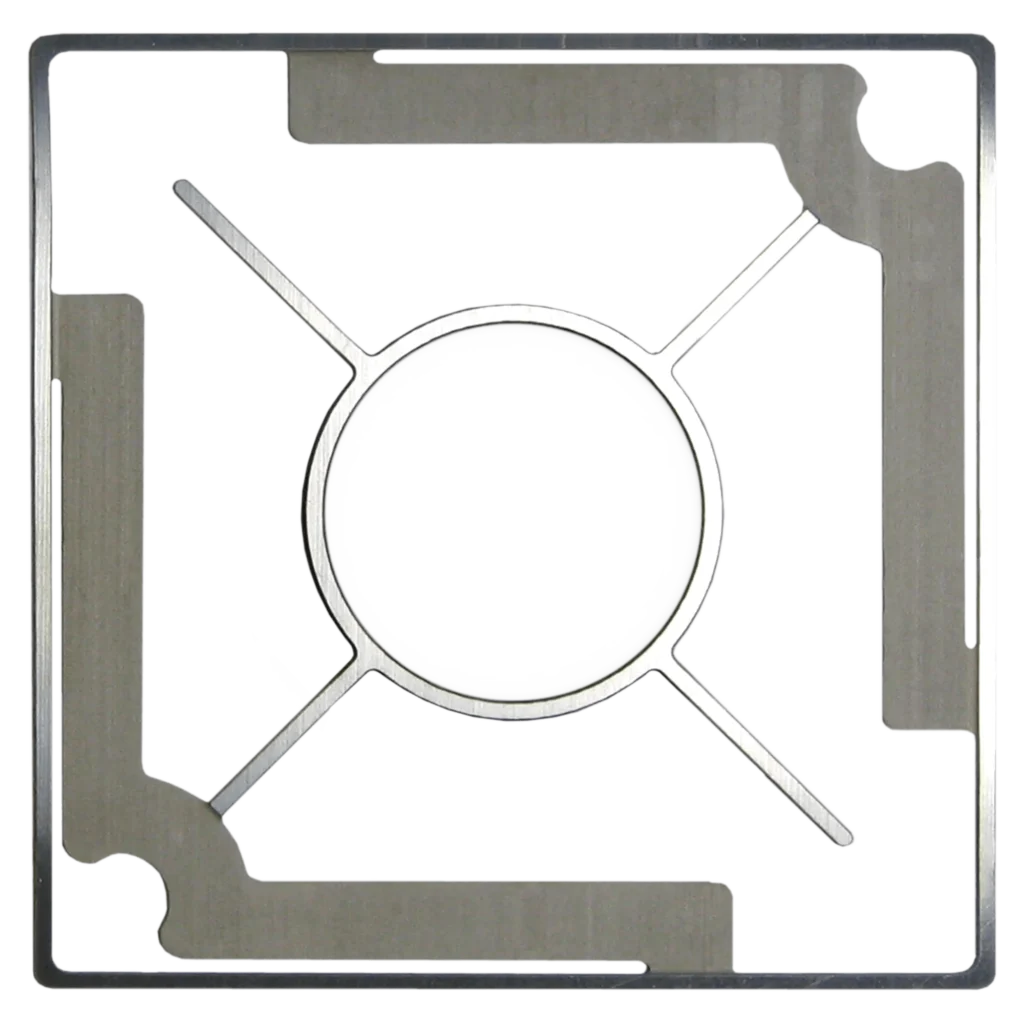

At PEI, we specialize in delivering custom precision metal shims with intricate geometries, tight tolerances, and superior surface finishes. As your trusted partner for advanced photo chemical etching techniques, we ensure each shim is manufactured to exacting standards, providing reliable, high-performance solutions for your unique applications.

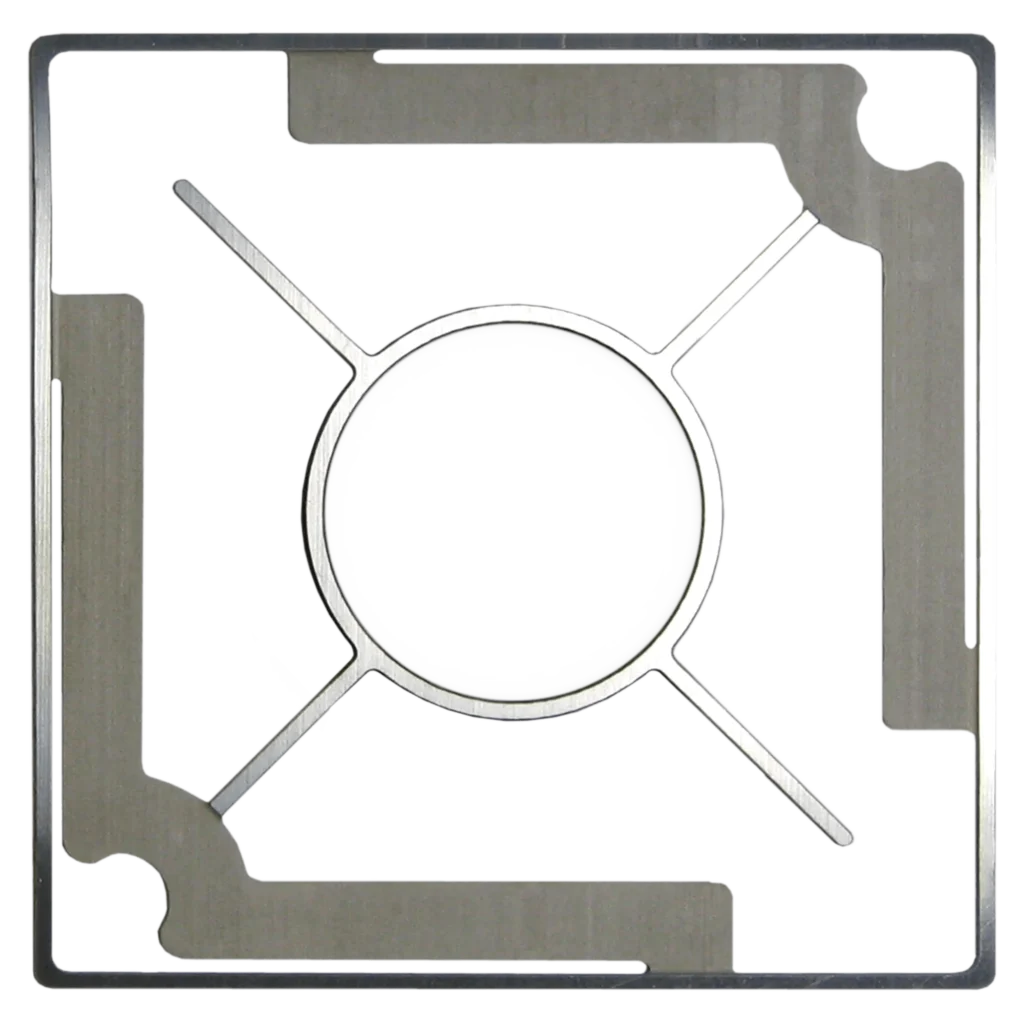

We manufacture custom shims in a variety of shapes and sizes, along with spacers and thin washer shims, which can be supplied either flat or formed based on your design specifications. By combining cost-efficiency, material expertise, and technical precision, we produce affordable, high-quality shims ideal for a diverse range of industries and applications.

With our flexible photochemical etching process and digital tooling capabilities, PEI produces custom shims quickly and efficiently, ensuring affordability and precision.

Precision shims are customized washers or thin spacers crafted from sheet metal or metal sheet, designed to absorb impact, minimize movement, and protect material surfaces in complex mechanical assemblies. These precise shims are essential for achieving alignment, precision, and stability in high-performance applications.

Typically manufactured using materials like stainless steel, brass, or copper, these shims compensate for tolerances and irregularities, ensuring a perfect fit and smooth operation of machinery. Many industries, including aerospace, automotive, and industrial manufacturing, rely on precision shims for reliable alignment and alignment accuracy.

Photochemical etching allows PEI to produce precision shims that are extremely accurate, making them the preferred choice for industries with strict tolerances.

Custom shims are critical for a wide range of applications. Essential in ensuring precision alignment and precise alignment, shims contribute to stability and efficiency in the manufacturing and operation of equipment.

Our precision shims help achieve optimal performance across various industries by delivering a proven solution to alignment challenges.

Aerospace: Used for structural alignment, vibration dampening, and ensuring precise fit between components in aircraft.

Defense: Critical for accurate scopes, gun sights, and navigation systems.

Critical in engine assemblies, transmission systems, and suspensions to ensure smooth operation and noise reduction.

Enable structural and functional alignment in renewable energy equipment, such as wind turbines and solar panels.

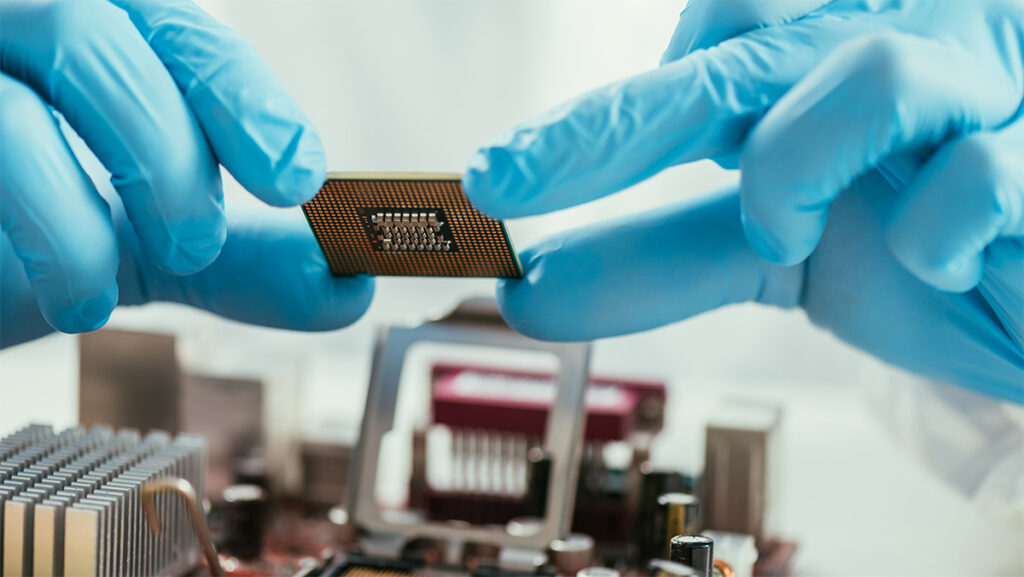

Thin, conductive shims enhance the performance of circuit boards, connectors, and microelectronics.

Support intricate assemblies in surgical tools, diagnostic equipment, and other medical devices.

Essential for alignment and gap adjustments in pumps, compressors, and heavy machinery.

At PEI, our specialized team is an expert in photochemical etching, consistently delivering custom metal shims tailored to the exact requirements of their application. Our proven process is executed with meticulous attention to detail and utmost precision to ensure these intricate components are delivered to exact specifications and boasts the highest levels of corrosion and wear resistance.

At PEI, we combine technical expertise, state-of-the-art manufacturing processes, and a commitment to quality to produce custom precision metal shims that meet the most demanding requirements.

When you choose PEI, you get access to:

As the world leader in precision chemical machining, we consistently deliver precise, durable, and reliable quality shims you won’t find anywhere else.

Our continuous investment in cutting-edge technology and top-tier talent ensures we can manufacture custom metal shims for applications across a diverse range of industries.