An encoder is a hidden hero in dozens of applications, from medical diagnostic devices to printers to industrial drilling machines. The highly precise sensing device provides motion feedback to electronics that control the motion of a device or machine.

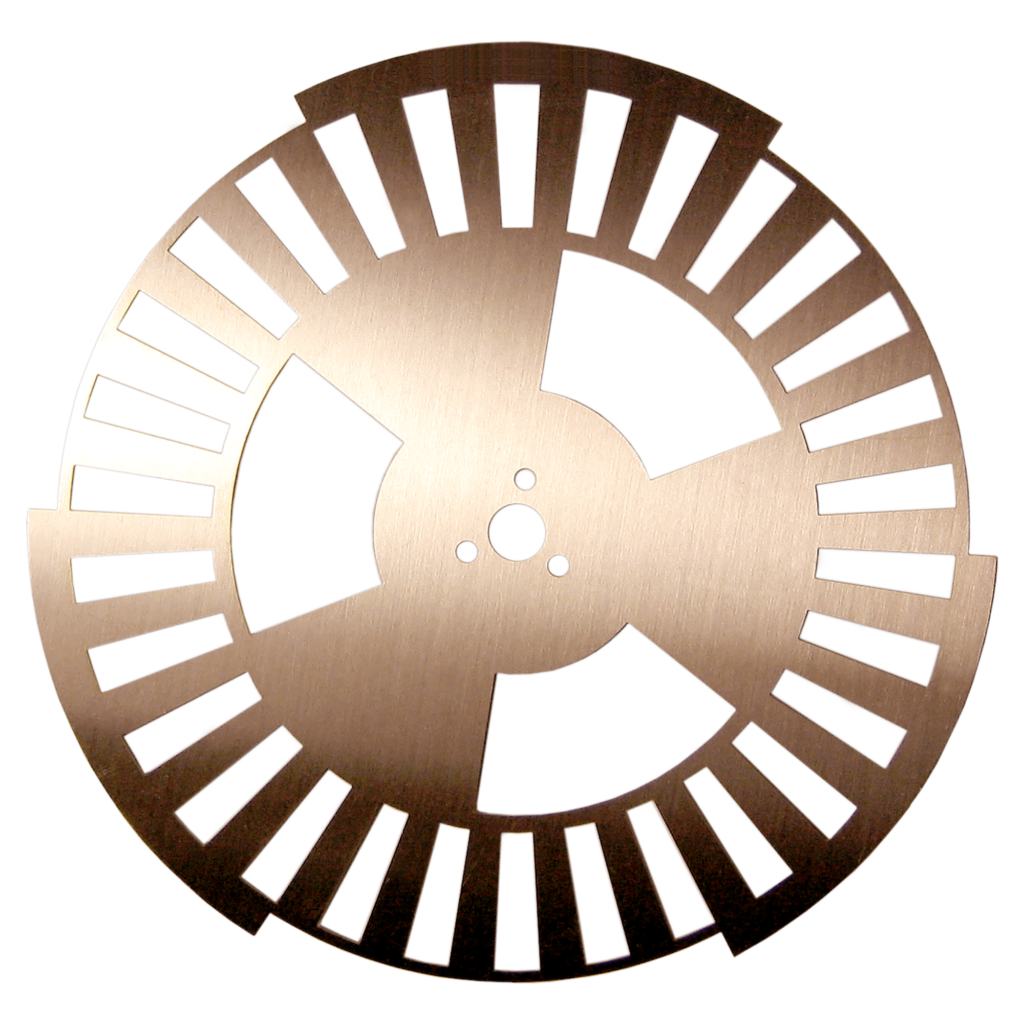

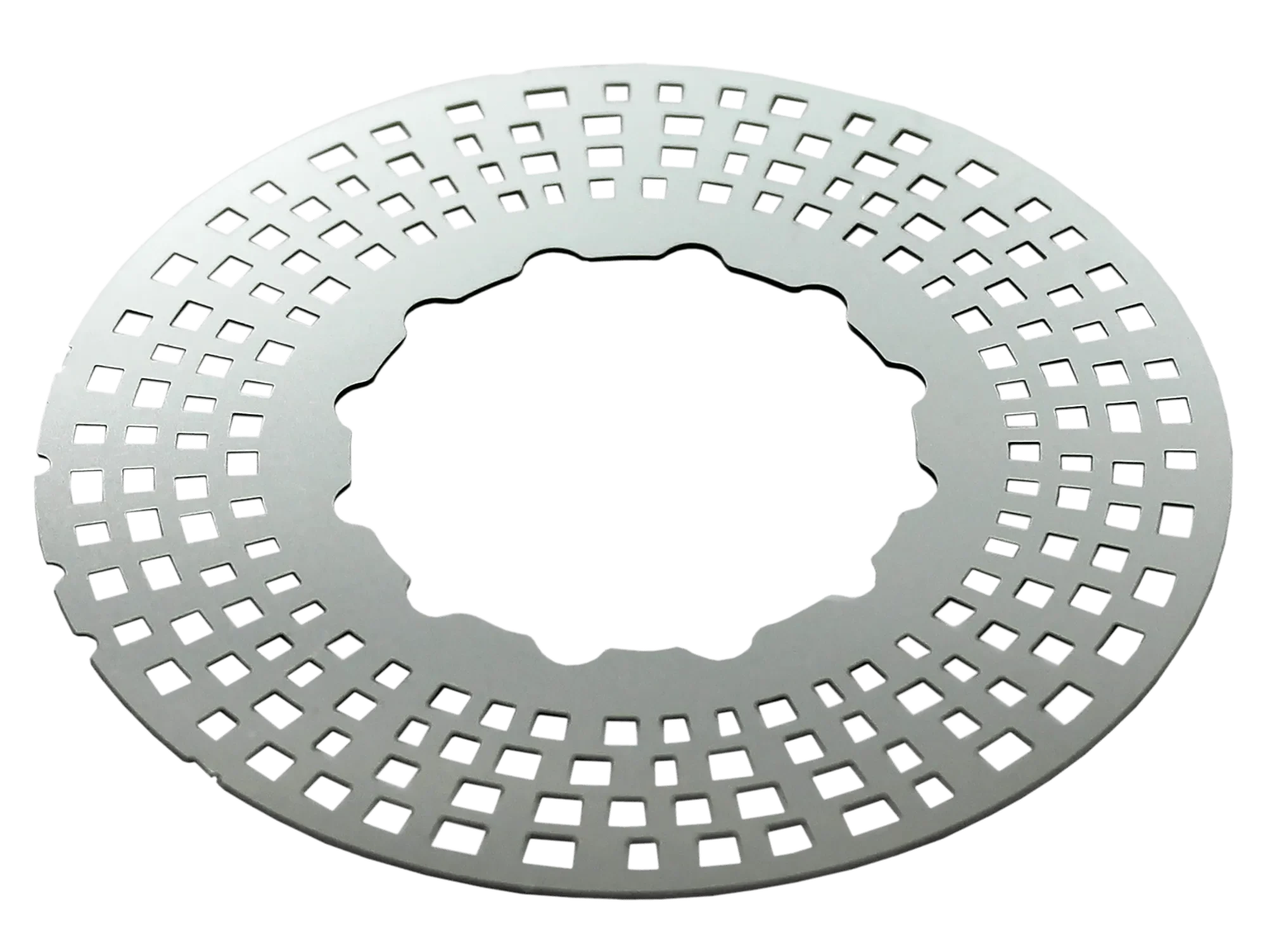

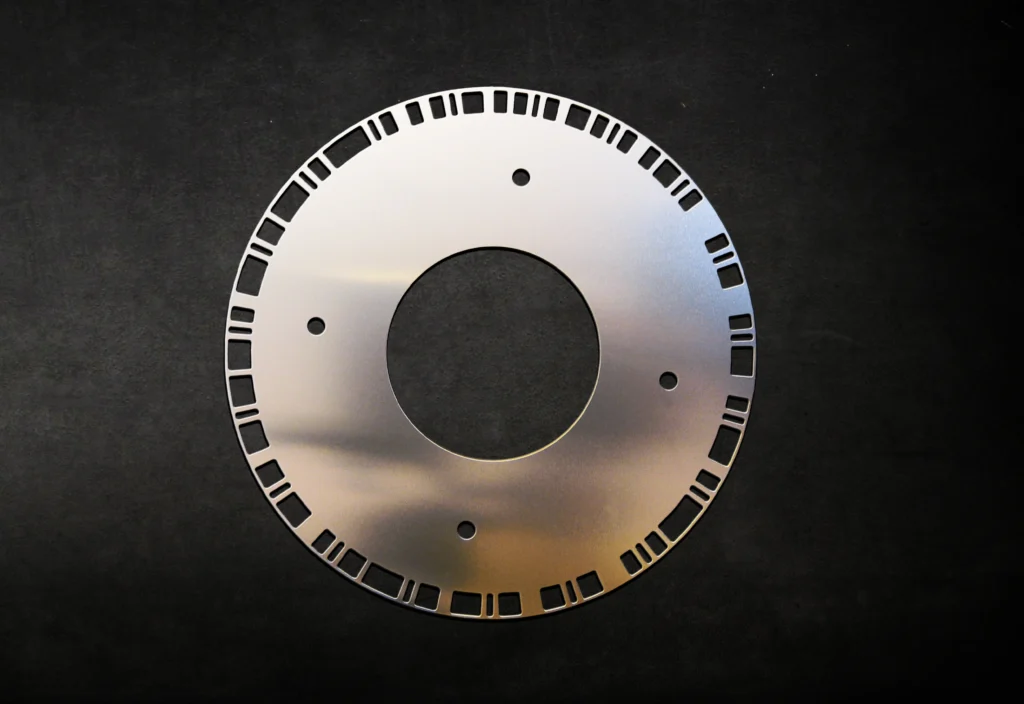

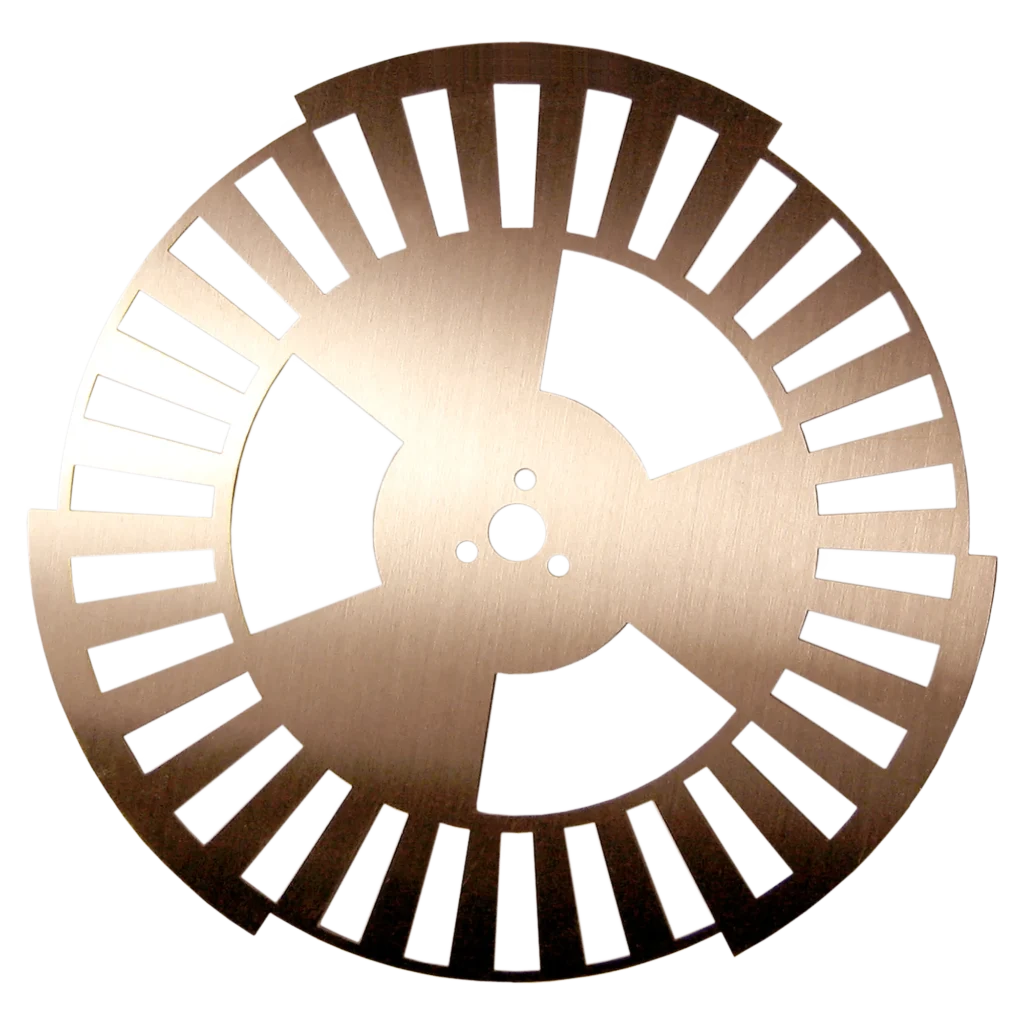

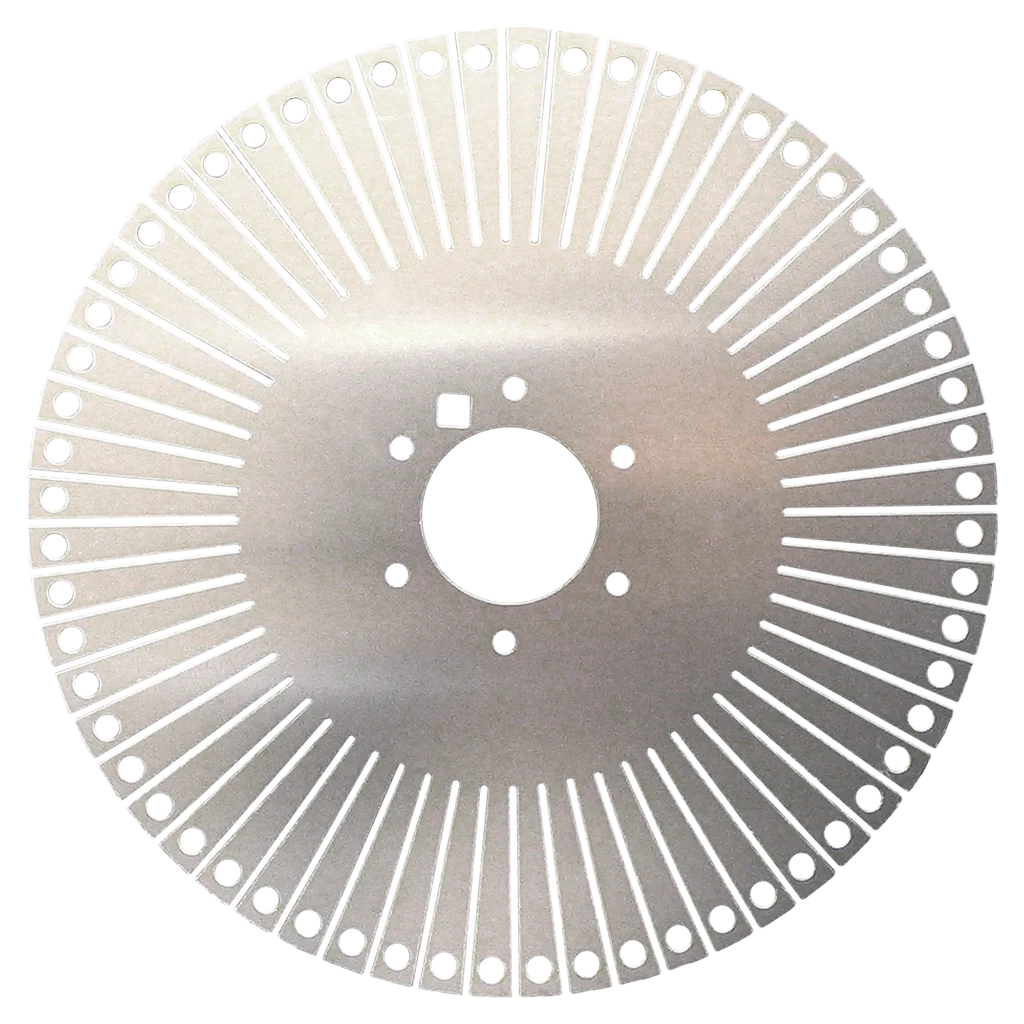

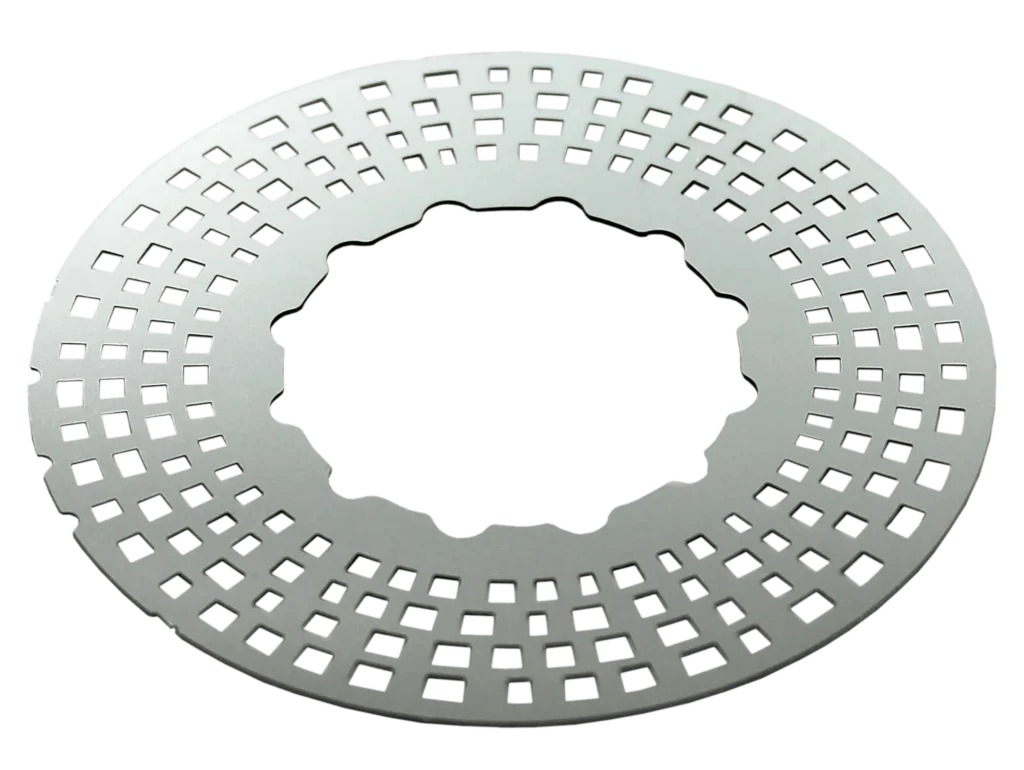

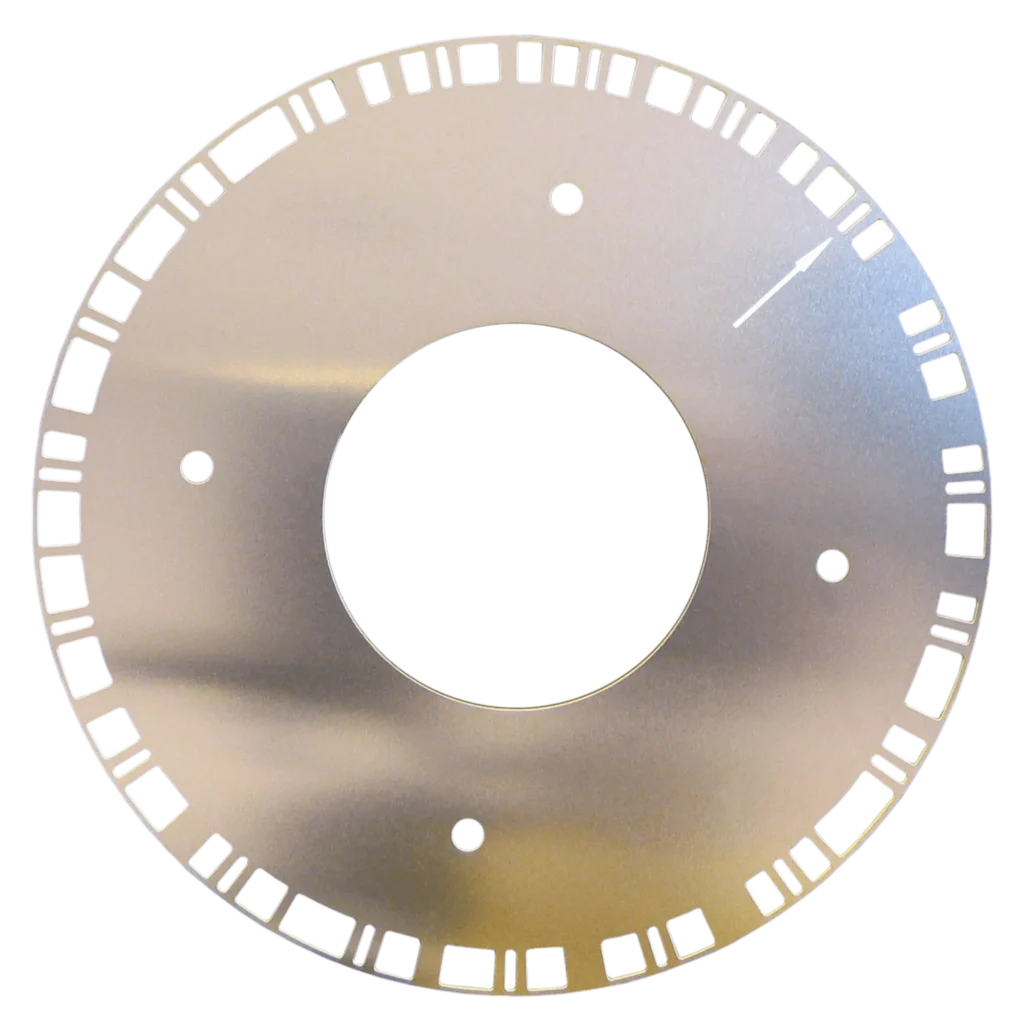

Encoder wheels, encoder discs, and encoder strips are essential parts of an encoder, and each part must be fabricated to the most stringent specifications.

PEI excels in manufacturing custom encoder wheels and discs tailored to our client’s specifications. Leveraging our expertise in precision photochemical etching our encoder components are engineered with unparalleled precision and maintain strict dimensional tolerances.

An encoder is a sensing device that provides critical feedback by converting motion into electrical signals, which control devices in industrial electronics and motion control systems can interpret.

We know their integration into complex electronic devices and systems, encoders, encoder disks, encoder wheels, and encoder strips necessitate intricate and precise engineering to perform reliably and effectively.

PEI’s decades of experience producing precise parts used in encoders means we are experts in using a variety of metals. We can prototype and produce custom precision chemical machine encoder parts in these materials:

Aluminum

Brass

Copper

Inconel 600

Nickel Alloys

Stainless Steel

PEI operators produce precision encoder parts used by industry-leading companies serving the automotive, consumer electronics, aerospace, industrial manufacturing, material handling, medical, defense, and scientific instruments sectors.

Encoders are pivotal in enhancing vehicle safety and performance through precise motion control. They provide critical feedback for optimal vehicle handling and driver assistance systems.

Encoders provide accurate feedback for life-saving equipment. They ensure enhanced patient safety and treatment outcomes, from robotic surgical systems to patient monitoring devices.

Encoders excel in demanding environments, providing reliable operations for aircraft systems. They ensure precise positioning and feedback, contributing to safety and efficiency.

Photochemical etching, also known as precision chemical machining, chemical blanking, or acid etching, is an exact subtractive manufacturing process where chemical etchants selectively remove metal from a thin sheet to create intricate shapes, patterns, and features. Unlike traditional methods, photochemical machining does not involve mechanical force or direct contact with the sheet of metal, minimizing the risk of distortion, burrs, or stress-induced deformation.

The benefits of photochemically etching encoder parts include fabricating precise parts with intricate geometries and accurate patterns.

Here are additional benefits of titanium photochemical etching:

With a history of engineering excellence, PEI is among the top companies providing photochemically etched metal parts and components for various critical industries.

With ISO-9001:2008 and AS9100 certifications, PEI was also granted certification under the International Traffic in Arms Regulation (ITAR) in 2010, enabling it to provide weapon system components and accessories in compliance with the Code of Federal Regulations implemented by the U.S. Department of State.

Our rigorous inspection processes and testing procedures ensure that every product we produce meets stringent accuracy, reliability, and performance standards.