The expert team at PEI has established a reputation for manufacturing high-precision bipolar plates through advanced photochemical etching, specifically for hydrogen fuel cells and electrochemical energy devices. Our custom-designed fuel cell plates are engineered for optimal flow performance, excellent electrical conductivity, and long-term corrosion resistance.

As a trusted manufacturing partner to leading renewable energy companies, we’ve delivered thousands of precision metal parts, components, and assemblies that power the global transition to clean energy.

The transition to renewable energy is accelerating, with record investments driving demand for efficient, scalable components. To achieve a cleaner energy future, companies must design and produce thousands of thin metal parts that form the foundation of fuel cell technology, solar, wind, and other energy systems.

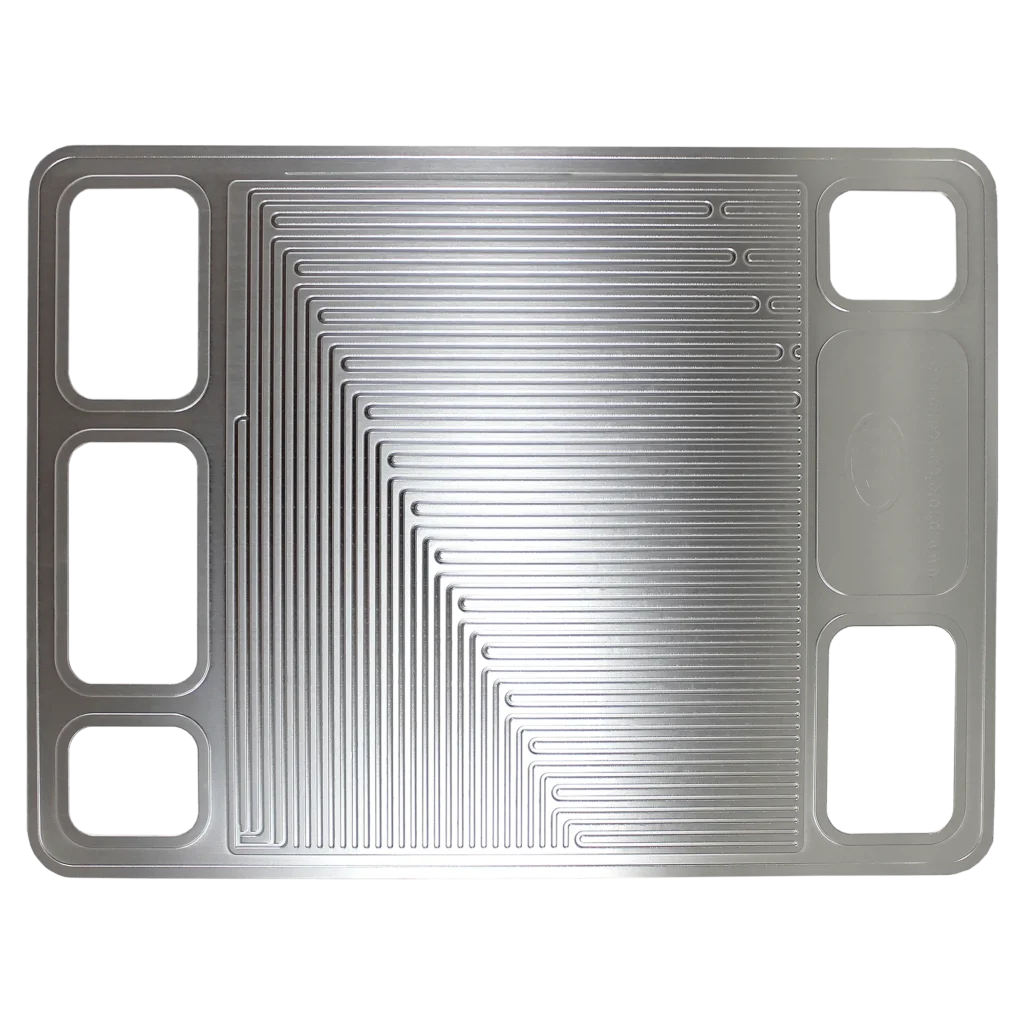

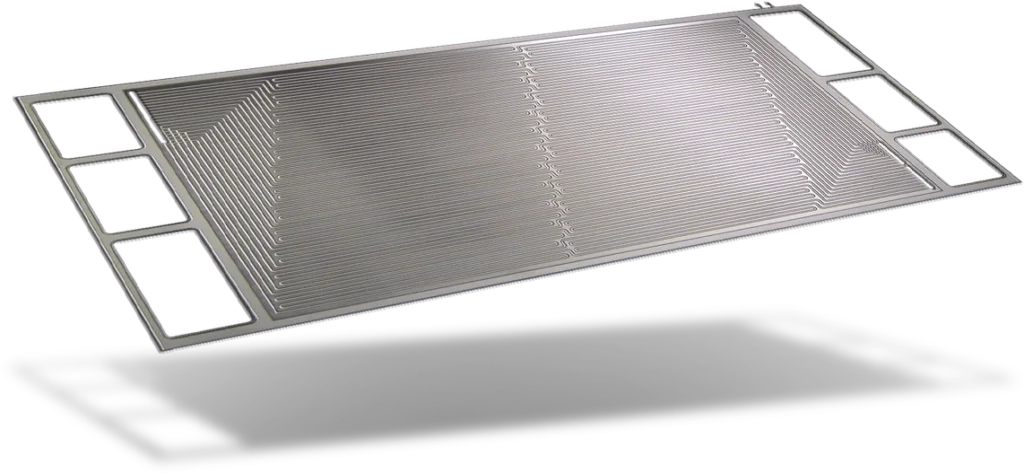

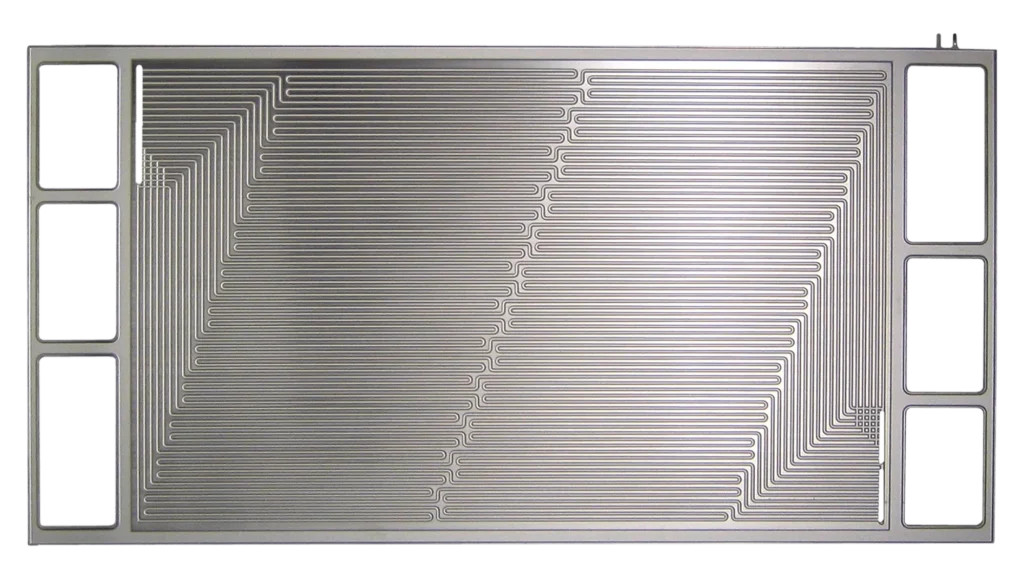

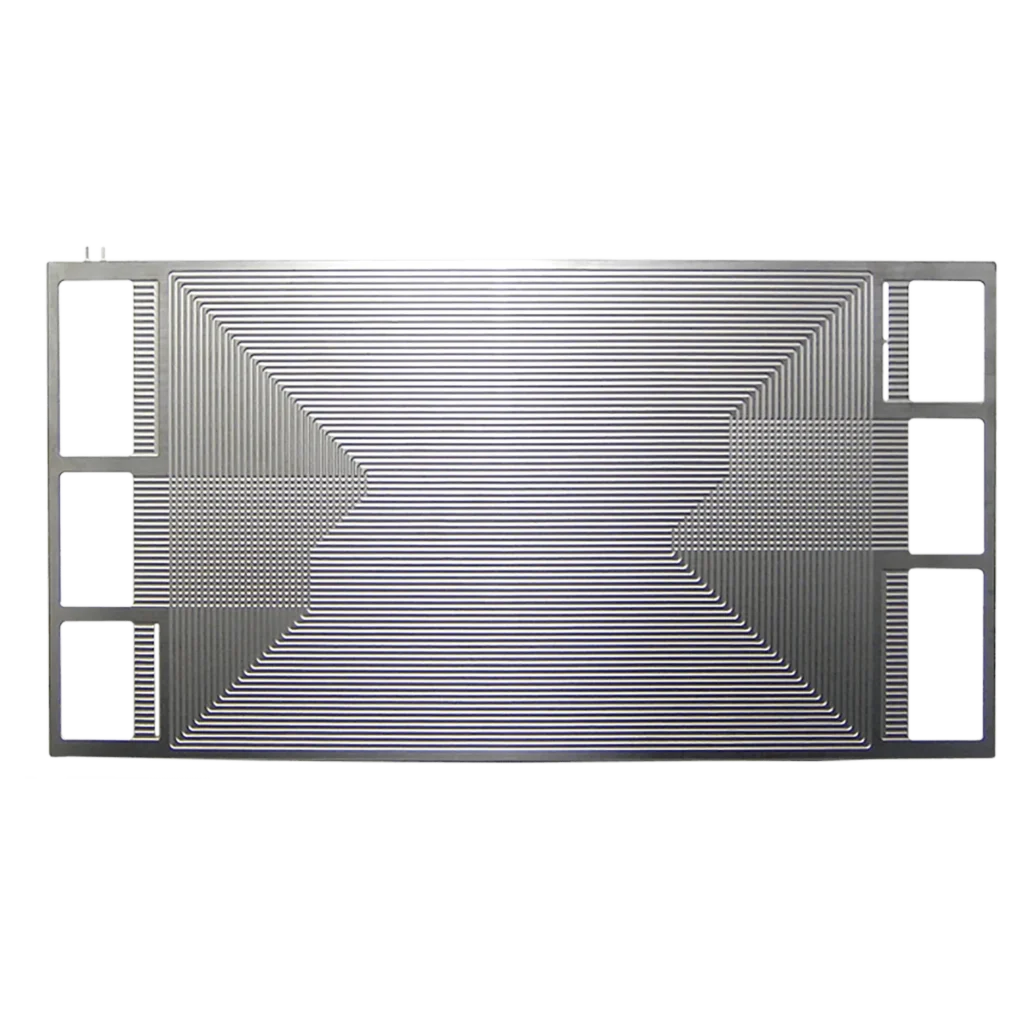

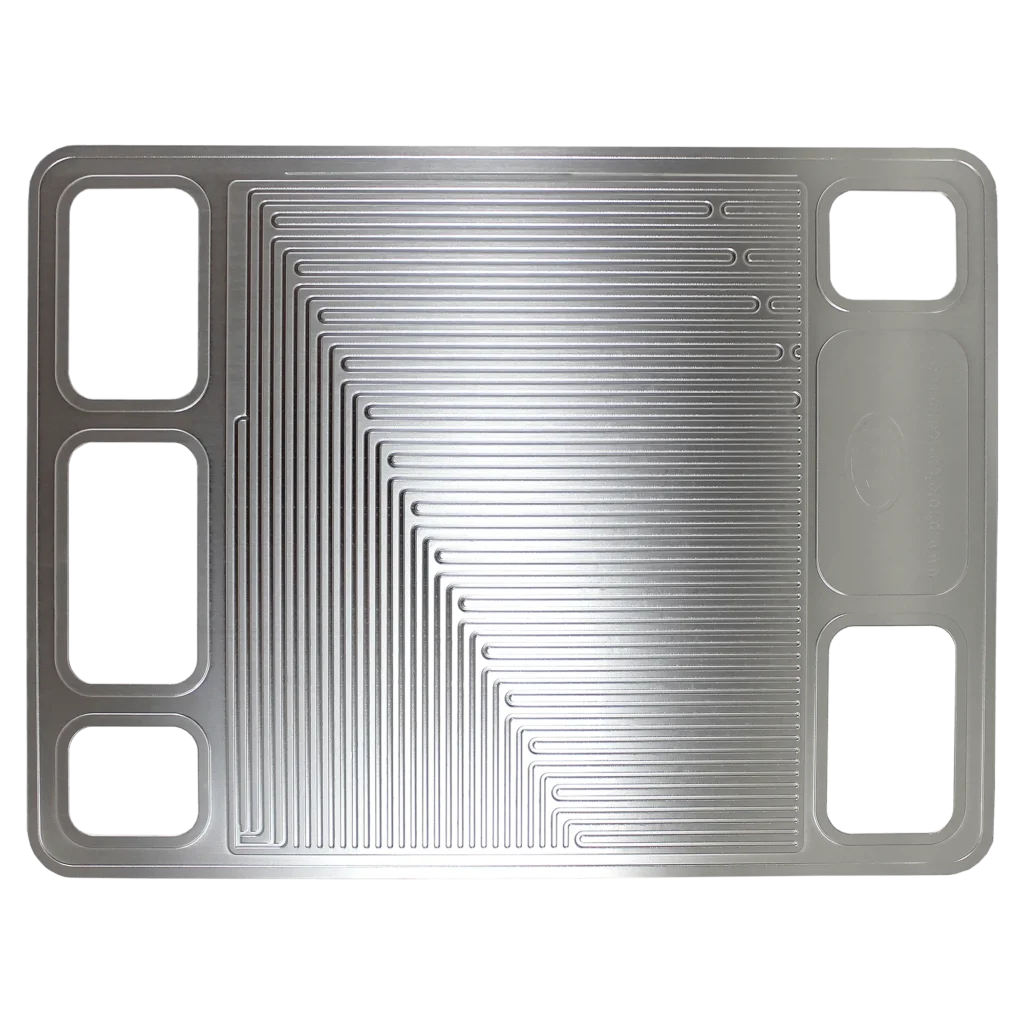

Within hydrogen energy systems, bipolar plates connect individual fuel cells, forming the fuel cell stack that powers everything from vehicles to backup energy systems. In both proton exchange membrane (PEM) and solid oxide fuel cells, the bipolar plate serves as the critical conductive path between cells, enabling gas separation while maintaining structural integrity.

Because plates typically need to be thin, lightweight, and corrosion-resistant, their design directly impacts efficiency, durability, and usable output voltage.

Bipolar plates are essential to stack performance, ensuring every cell operates efficiently and reliably. Their ability to manage thermal loads, maintain gas separation, and provide electrical conduction makes them one of the most important components in advanced energy systems.

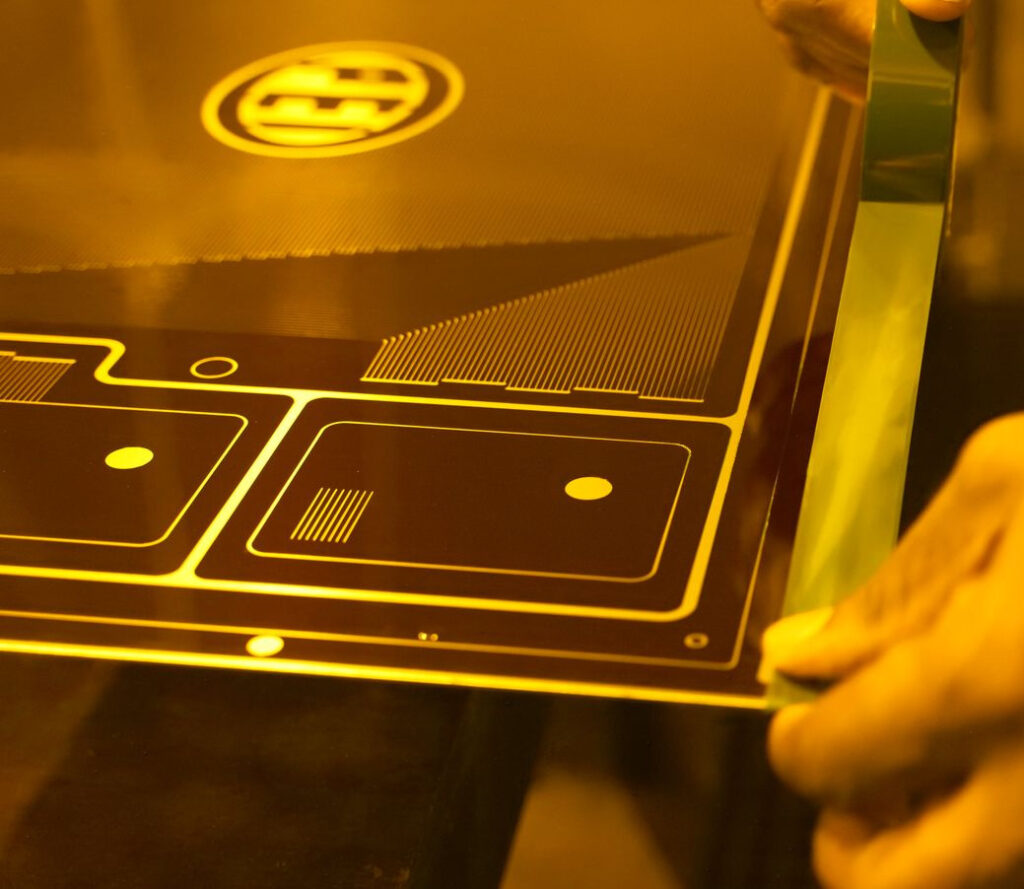

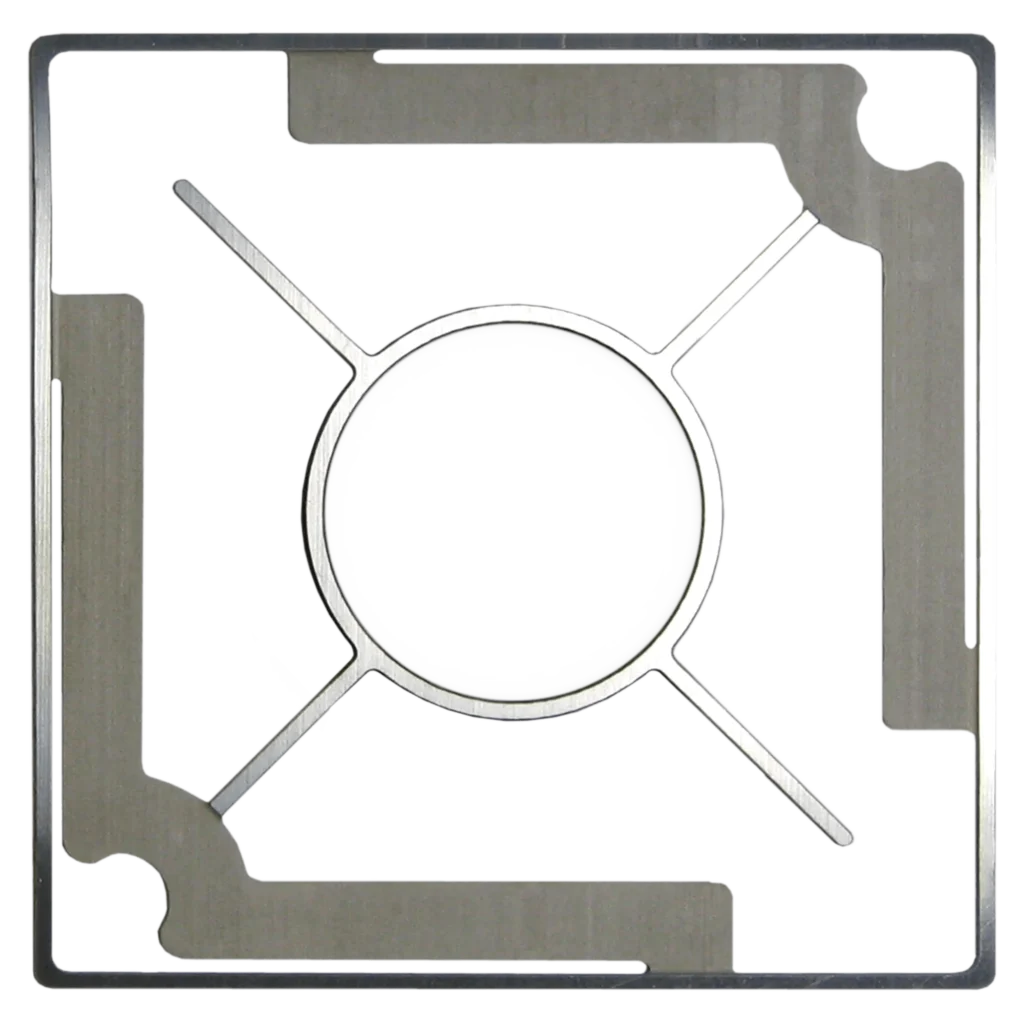

PEI’s expertise in photochemical etching gives energy innovators a unique edge when designing and scaling metallic bipolar plates. Unlike stamping or machining, our process maintains the integrity of thin metals while allowing engineers to introduce complex flow field geometries without added cost or distortion.

The result is a manufacturing approach that combines precision, flexibility, and repeatability – critical qualities for next-generation hydrogen and electrochemical systems.

PEI sets the industry standard for precision in metallic bipolar plates:

Our fuel cell plates are available in a range of high-performance materials designed to withstand harsh operating environments:

Some of the key applications of our precision etched plates include:

As experts in the production of bipolar plates, PEI serves customers in industries such as:

In stationary fuel cell systems, our bipolar plates ensure consistent and reliable power generation and efficient energy output. Their ability to withstand harsh operating conditions and maintain optimal performance is essential for uninterrupted energy delivery.

Bipolar plates are crucial in developing fuel-cell electric vehicles (FCEVs), enhancing performance, reliability, and longevity in automotive applications. They are integral to the industry’s move towards environmentally friendly transportation solutions.

Bipolar plates are found in fuel cell systems that demand high efficiency and reliability for optimal performance in challenging environments. Their lightweight yet robust design and exceptional conductivity and corrosion resistance make them ideal for aerospace applications.

Every fuel cell program comes with its own unique performance requirements, and PEI’s photochemical etching process is built to adapt. From one-off prototypes that demand rapid design changes to large-scale production runs requiring consistency and repeatability, our team works alongside engineers to optimize designs for manufacturability while meeting strict energy-sector standards.

PEI offers complete flexibility for your fuel cell program:

Whether you’re developing a proof-of-concept or scaling to high-volume production, PEI has the expertise and capacity to deliver.

With a history of engineering excellence, PEI is among the top companies providing photochemically-etched metal parts and components for a variety of critical industries.

With ISO-9001:2008 and AS9100 certifications, PEI was also granted certification under the International Traffic in Arms Regulation (ITAR) in 2010, enabling it to provide weapon system components and accessories in compliance with the Code of Federal Regulations implemented by the U.S. Department of State.

Our rigorous inspection processes and testing procedures ensure that every product we produce meets stringent accuracy, reliability, and performance standards.