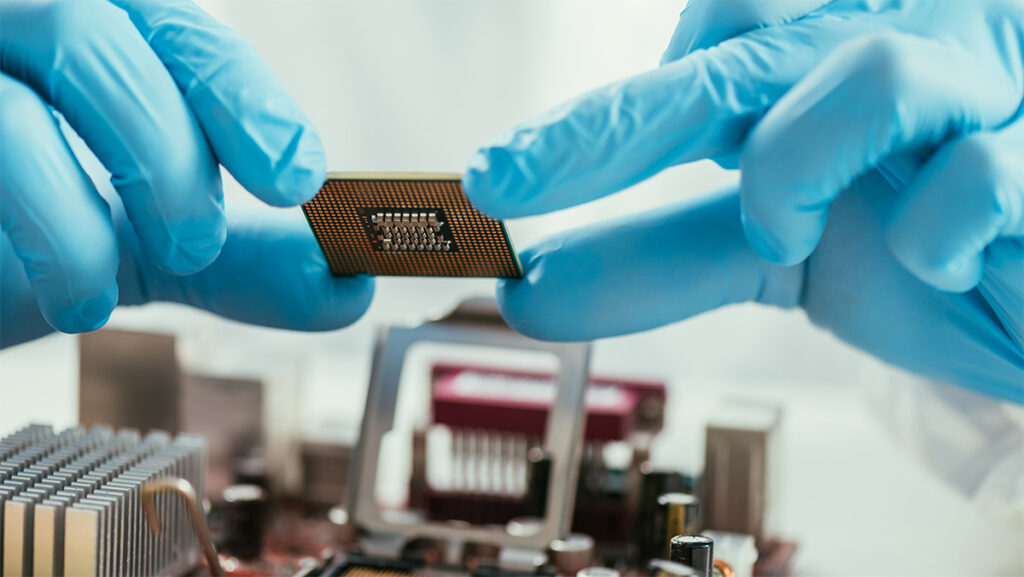

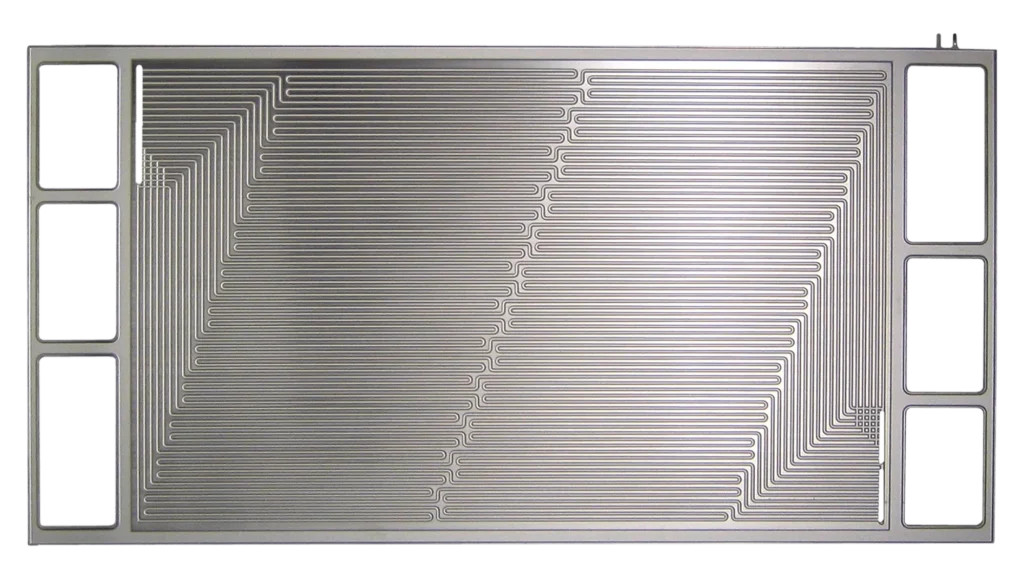

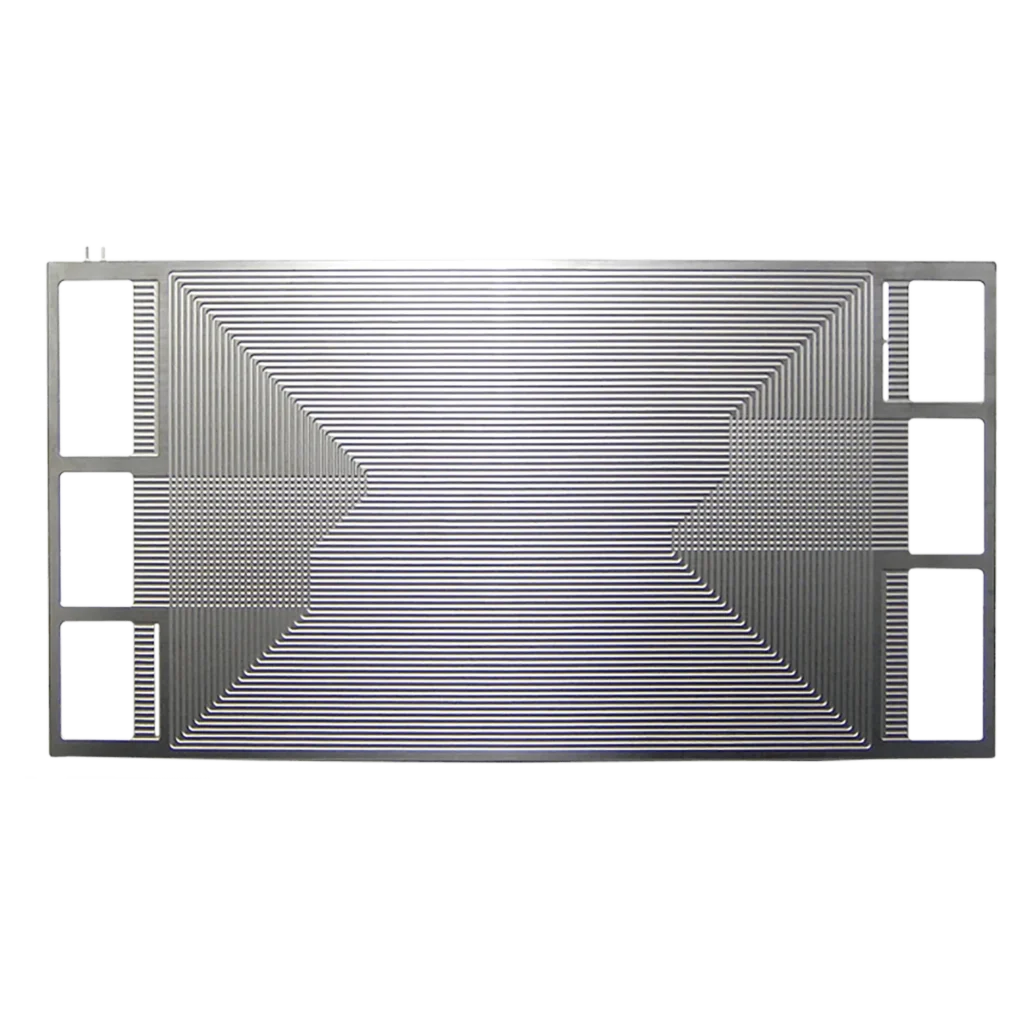

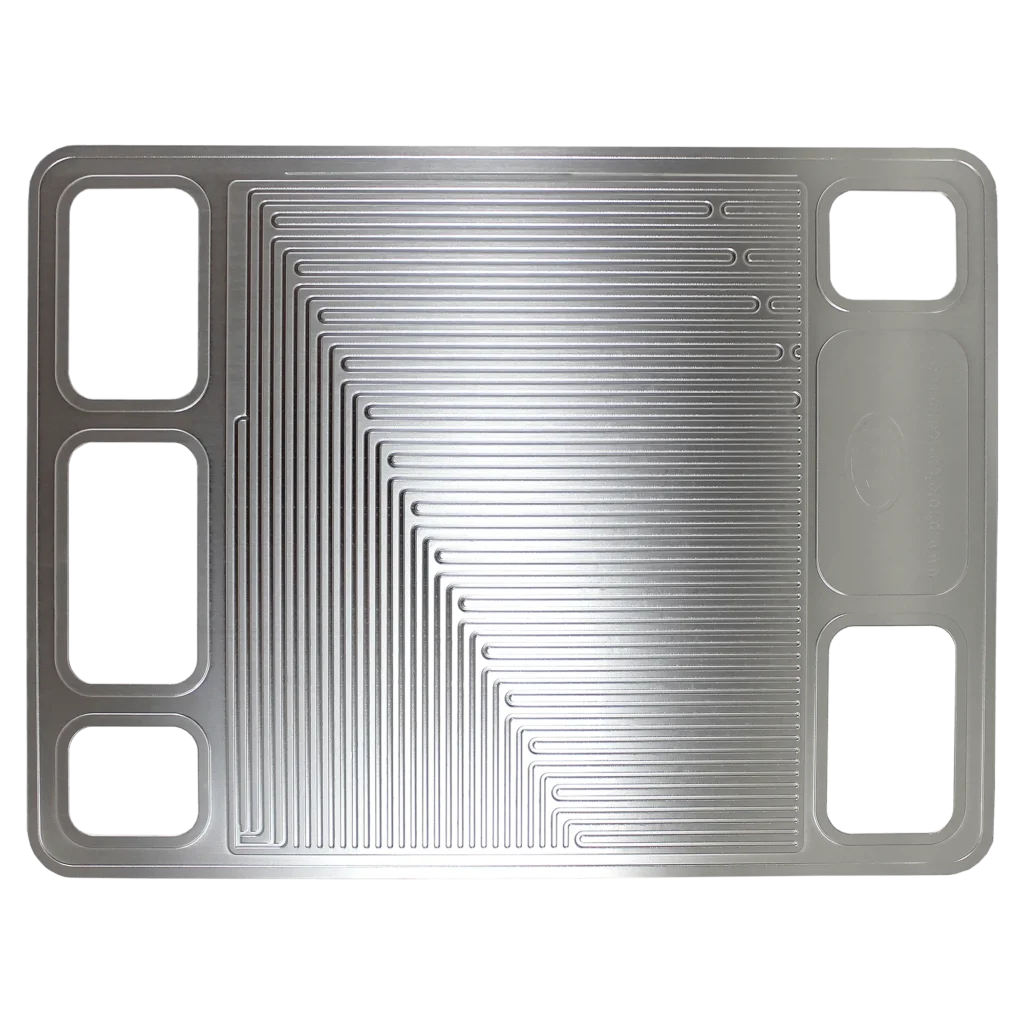

PEI is at the forefront of precision metal manufacturing, delivering precision photochemically etched anodes and cathodes that drive advancements in modern battery technology. Our innovative etching techniques allow us to create highly intricate and precise electrode components, optimizing energy storage and efficiency for next-generation batteries.

By leveraging innovative designs and advanced material optimization, PEI enables the production of lightweight, high-performance energy solutions across diverse industries, from electric vehicles to renewable energy storage.

As the need for clean energy grows, so does the demand for sustainable and cost-effective manufacturing. PEI’s environmentally conscious approach and precision etching capabilities are driving innovation across the energy sector and helping to deliver next-generation lithium-ion batteries.

Battery anodes and cathodes are the essential components of modern energy storage systems, forming the positive and negative electrodes that enable the flow of electrical energy in an electrochemical cell. The anode material, often made from graphite, silicon, or lithium metal, serves as the negative electrode, releasing electrons during discharge. On the other hand, the cathode active materials, such as lithium iron phosphate (LFP) or nickel manganese cobalt (NMC), form the positive electrode, efficiently storing and releasing energy.

These electrodes are crucial for achieving high energy density, ensuring longer-lasting power in applications like electric vehicles and grid storage. As the efficient energy storage industry advances, optimizing anode and cathode materials plays a key role in developing sustainable energy storage solutions that enhance performance, longevity, and environmental responsibility.

PEI’s highly precise manufacturing process enables us to produce intricate, high-performance anodes and cathodes for modern batteries, ensuring superior efficiency and reliability in every electrochemical cell.

Battery anodes and cathodes are critical components in a wide range of industries, driving advancements in energy storage and efficiency.

Our precision anodes and cathodes are driving innovation right across the energy sector and helping to transition the world to a cleaner energy future.

Renewable Energy

Automotive

Aerospace

Transportation

Industrial

Essential for high-capacity, fast-charging batteries in EVs, supporting the shift toward sustainable transportation.

Key components in batteries used for storing energy from solar, wind, and other renewable sources.

Optimize battery performance in devices such as smartphones, laptops, and wearables.

Support long-lasting, reliable power in devices like pacemakers, hearing aids, and surgical tools.

Enable lightweight, high-capacity batteries for satellites, drones, and other advanced technologies.

Power autonomous systems, robotics, and other heavy-duty machinery requiring durable and efficient batteries.

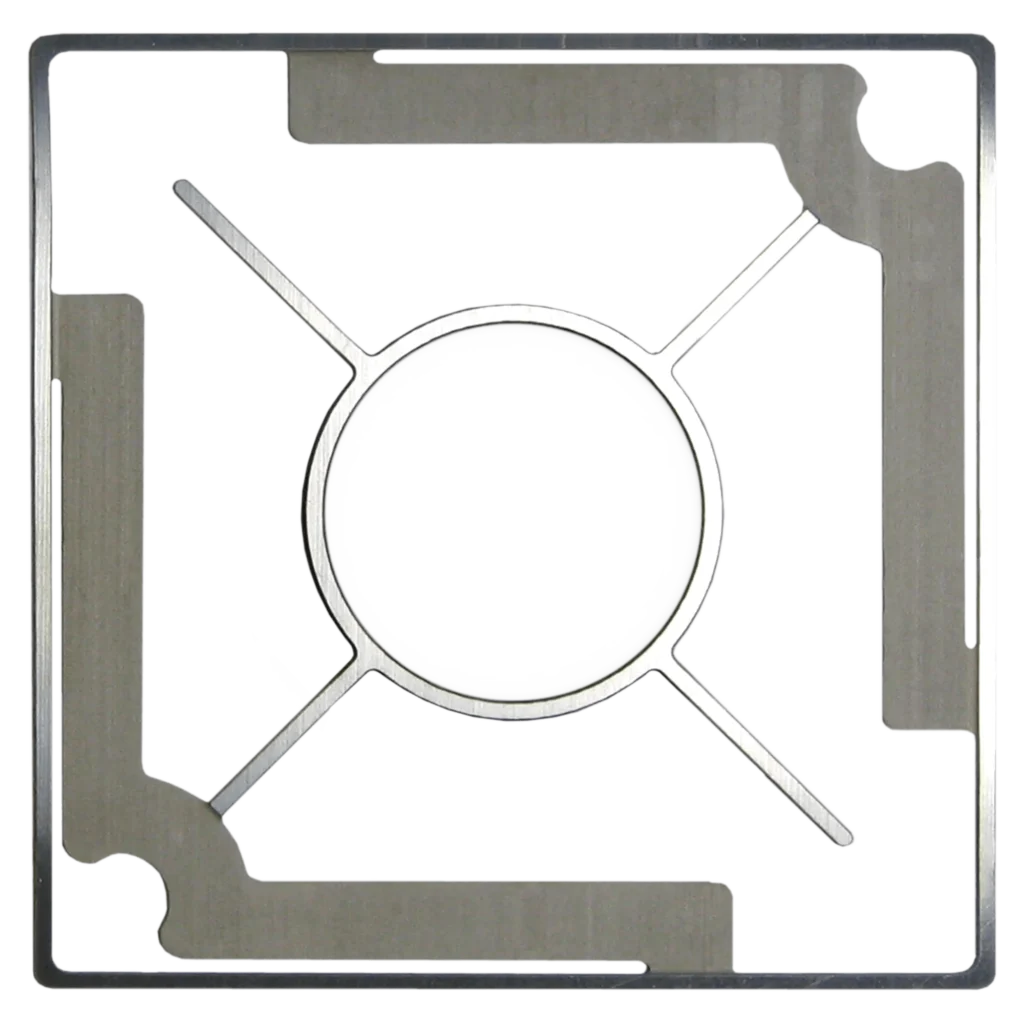

At PEI, our specialized team are expert in photochemical etching, consistently delivering precision anodes and cathodes tailored to the exact requirements of their application. Our proven process is executed with meticulous attention to detail and utmost precision to ensure these intricate components are delivered to exact specifications.

At PEI, we combine technical expertise, state-of-the-art manufacturing processes, and a commitment to quality to produce precision anodes and cathodes that are essential components of modern energy storage systems.

When you choose PEI, you get access to:

The team at PEI are experts at working with diverse metals and alloys for high-precision battery components.

In lithium-ion batteries, the cathode and anode materials play a crucial role in determining energy density, efficiency, and overall battery performance. The common cathode materials are typically metal oxides, including lithium cobalt oxide (LiCoO2), lithium manganese oxide (LiMn2O4), lithium iron phosphate (LiFePO4 or LFP), and lithium nickel manganese cobalt oxide (LiNiMnCoO2 or NMC).** Each of these positive electrode materials offers different advantages in terms of thermal stability, energy capacity, and cost-effectiveness.

On the negative electrode side, anode active materials are usually carbon-based, with graphite being the most widely used due to its high electrical conductivity, stability, and affordability. Silicon anodes are gaining popularity for their higher energy density, but they present challenges like volume expansion and shorter cycle life. To optimize performance, manufacturers often dope graphite anodes with small amounts of silicon, balancing stability and efficiency.

The cost of processing raw materials for cathodes accounts for 30-40% of a lithium battery cell’s cost, while anode materials make up about 10-15%. With the rising demand for sustainable battery solutions, the industry is increasingly focused on reusing valuable materials to reduce waste and enhance cost efficiency in battery production.

The anode is the negative electrode, which releases electrons during discharge, while the cathode is the positive electrode, which stores and releases energy. Together, they facilitate the flow of electricity in an electrochemical cell, enabling efficient energy storage and power delivery.

The choice of anode and cathode materials affects energy density, charging speed, cycle life, and overall efficiency. Graphite anodes are widely used for stability, while silicon anodes offer higher energy density but face volume expansion challenges. Common cathode materials like lithium cobalt oxide (LiCoO2), lithium iron phosphate (LFP), and NMC impact battery longevity, cost, and thermal stability, making material selection crucial for specific applications.

With years of experience in precision metal manufacturing, PEI continuously pushes the boundaries of electrode design and battery performance advancements.

Our low-cost digital tooling and scalable manufacturing capabilities allow us to produce high-quality battery components with cost efficiency at any production volume. We maintain strict quality control measures to ensure every electrochemical cell component meets industry standards for reliability, safety, and durability.