The technology sector is one of the fastest-moving and innovative in the world. PEI stands shoulder to shoulder with its technology partners, delivering precision metal parts and components used by industry-leading computer, communications, and microelectronics manufacturers. The engineers, manufacturers, and quality assurance professionals at PEI are ready to answer any challenge.

The PEI legacy of precision, dependability, and on-time delivery is essential when serving the technology sector, especially as the demand for faster, safer, and more reliable solutions. We are experts in photochemical machining, a manufacturing process that creates highly precise thin metal parts.

PCM allows for the production of parts from 0.0005 in. (0,0127mm) to 0.1250 in. (3.175mm) thick, which is essential as technology manufacturers look to reduce the weight of parts while maintaining strength and durability.

Our EMI and RF shield cans feature a patented, easy-access removable cover. This unique design allows users to quickly and easily replace or repair internal components without damaging the surrounding shield.

PEI is one of the few photochemical machining companies that can etch beryllium copper. Renowned for its exceptional hardness, strength, and thermal and electrical conductivity, this metal requires extra care because of the serious health hazards posed by beryllia dust.

Microwave Applications

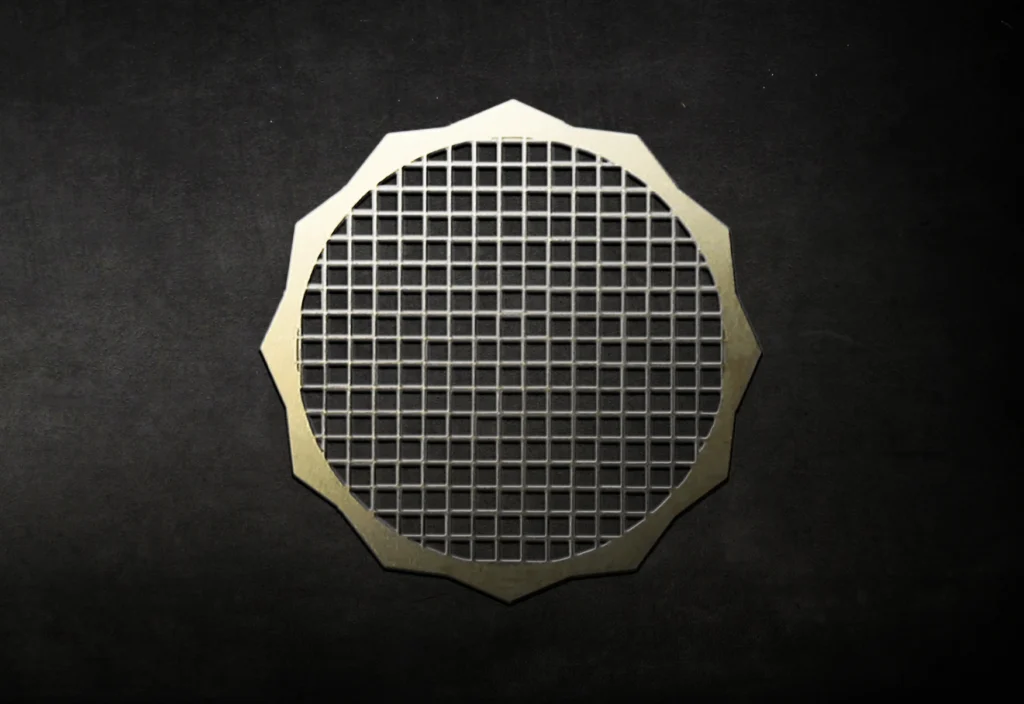

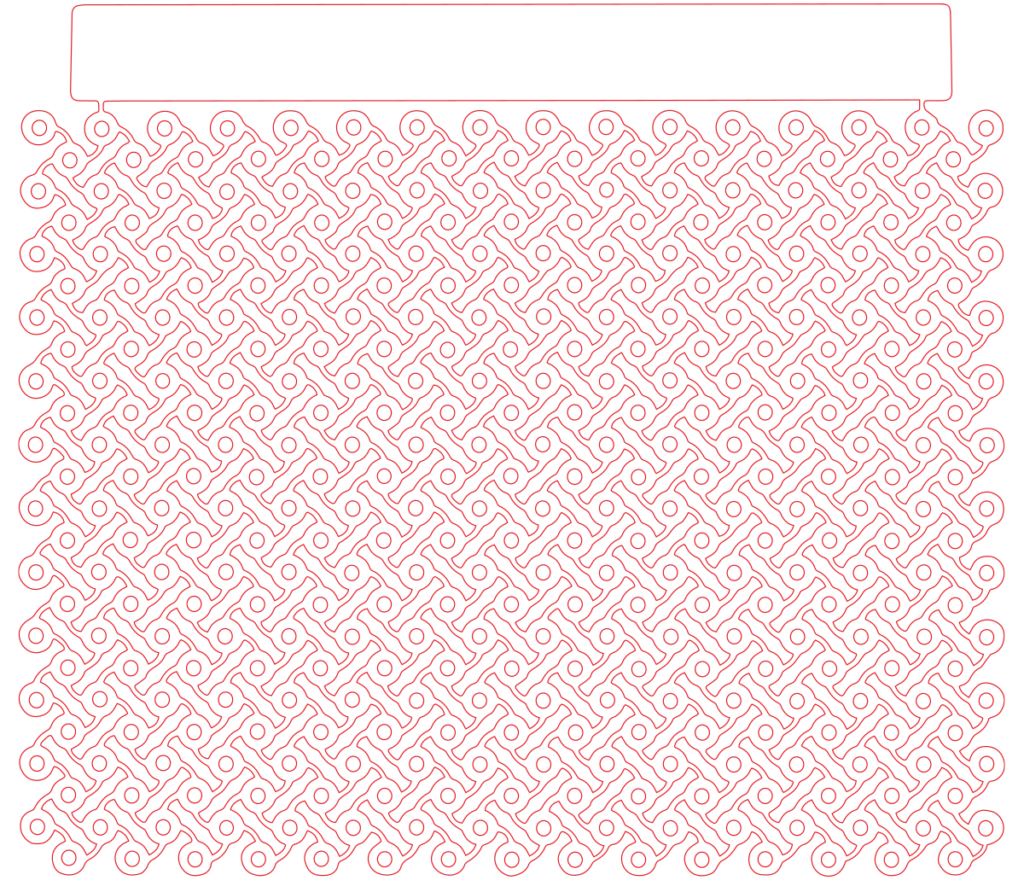

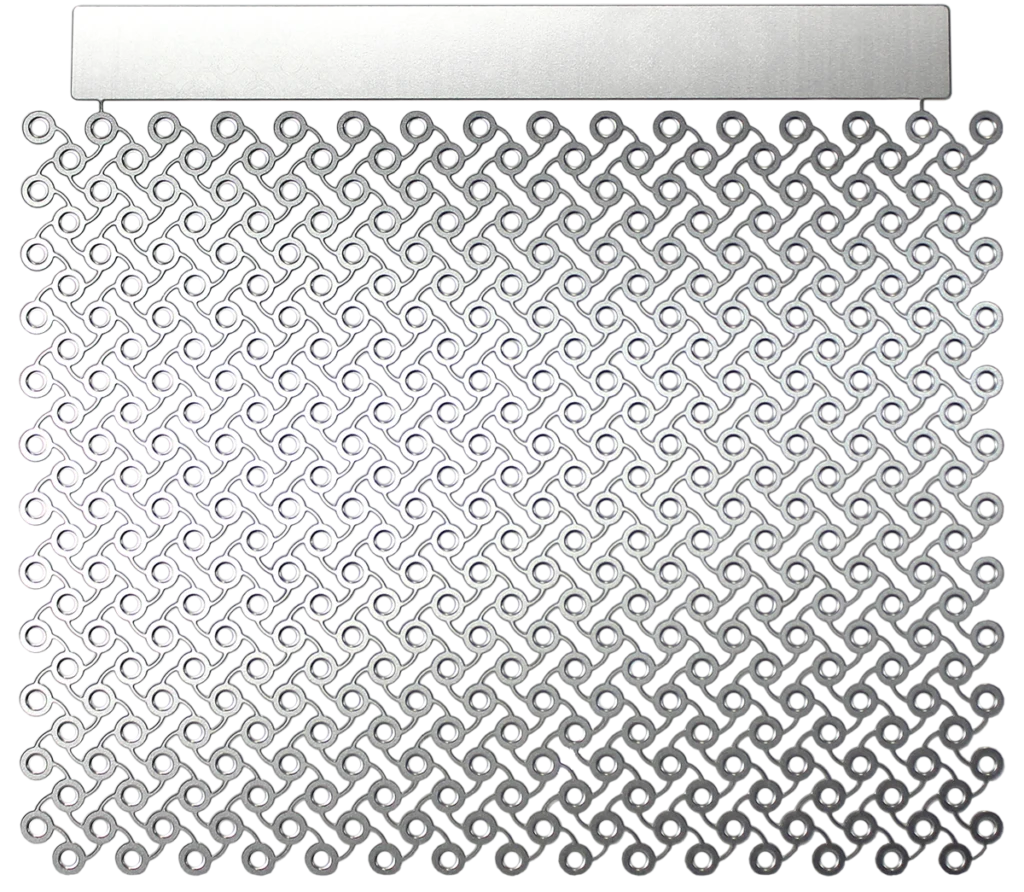

PEI is a leading supplier of mission-critical precision thin metal parts used in military and consumer microwave applications. We have a decades-long history of supplying the microwave industry with microwave circuits, electrical contacts, EMI shields, RF Shields, step lids, flat lids, gaskets, face plates, screens, and dozens of additional precision-etched metal components.

PEI specializes in precision chemically etched microwave circuits in various metals, including brass, copper, and beryllium copper. While other manufacturers refuse to work with beryllium copper, PEI’s development of a manufacturing process that safely mitigates the health hazards of beryllia dust makes it an industry leader, and our process is safer than stamping, machining, or cutting the metal.

We leverage the precision of photochemical etching to deliver greater tolerance control for elaborate parts, regardless of the material, and provide even the most intricately shaped products at a competitive price and with short delivery lead times.

PEI features a patented line of EMI/RF shielding cans and an easy-access removable cover designed to protect components from radio frequency/electromagnetic interference and environmental hazards, as well as to provide electrical grounding. Our unique design lets users quickly and easily replace or repair internal components without damaging the shield.

Our expert manufacturers produce custom-fabricated components used in vital consumer and military-grade communication devices. We work with engineers and designers to produce components that exceed stringent technical specifications.

Microelectronics Applications

PEI’s 55-year history includes innovations in microelectronics, delivering custom and standard metal parts such as lead frames, Kovar and molybdenum tabs, and chip carriers. We can etch virtually any metal, from basics like copper, brass, and stainless steel to precious metals (including silver) to exotic meals such as titanium, molybdenum, and beryllium copper.

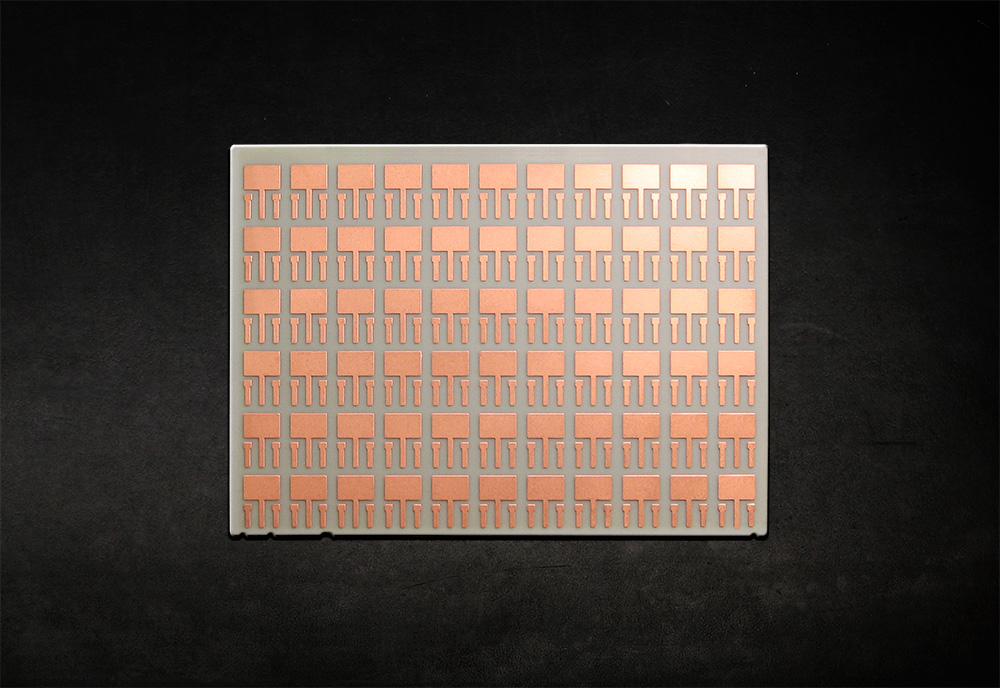

Leading microelectronics manufacturers call on us to produce surface-mount and insert-mount photochemically etched lead frames to meet exacting electrical, thermal conductivity, and strength requirements for companies providing integrated circuits. Engineers use these lead frames in semiconductors, glass-to-metal seals, and relays.

PEI can plate lead frames entirely or selectively after fabrication using a base material like Kovar, nickel-iron alloys, copper alloys, and pure nickel. Depending on the customer’s specific electrical and thermal conductivity requirements, lead-free plating materials include silver, nickel, gold, or tin. Since the lead frame is the main conduit by which heat flows from the chip to the printed circuit board, PEI tailors the manufacturing material to maximize the device’s operating life for any given application or environment.

PEI manufactures high-density lead frames with acute profiles and ultra-fine pitches, allowing for high pin counts. Single- or double-sided lead frames can be etched without incurring the stresses associated with typical machining methods. More importantly, PEI’s process can be used for lead frames that are too complicated for stamping. Dimensions can be held to extremely tight tolerances, with no burrs or other surface irregularities.

PEI’s lead frames range in thickness from 0.5 mil [0.0127 mm] to 40 mil [1.575 mm], with features as small as 4 mil [0.10 mm] on 0.010 in. [0.254 mm) centers, creating lead frames that are strong enough to be handled yet flexible enough to allow bending when necessary.

Industries and technologies evolve when people work together to push boundaries and uncover new solutions. For over 50 years, we’ve stood shoulder to shoulder as leading companies across every market sector push forward with revolutionary changes that change the world. We are ready to share and leverage knowledge and expertise to collaborate with our customers for mutual success.

PEI’s long history of meeting and exceeding industry standards and customer expectations began in 1968. For over 50 years, we’ve kept quality assurance at the forefront of our work by training our manufacturing teams, maintaining our equipment, and establishing rigorous internal controls. PEI holds several certifications, including ISO9001:2015, AS9100:2016, and ITAR. We adhere to MIL-STD-45662, MIL-STD-105, and ANSI/ASQC Z1.4 quality standards.