When the mission is to save the world’s environment, precision is the only option. PEI brings decades of experience and industry-leading expertise to take on the challenge every day. Our team of engineering, production, and quality assurance technicians delivers precise, reliable, and durable solutions to our industry partners used in hydrogen production power plants, solar panels, wind turbines, and energy storage systems.

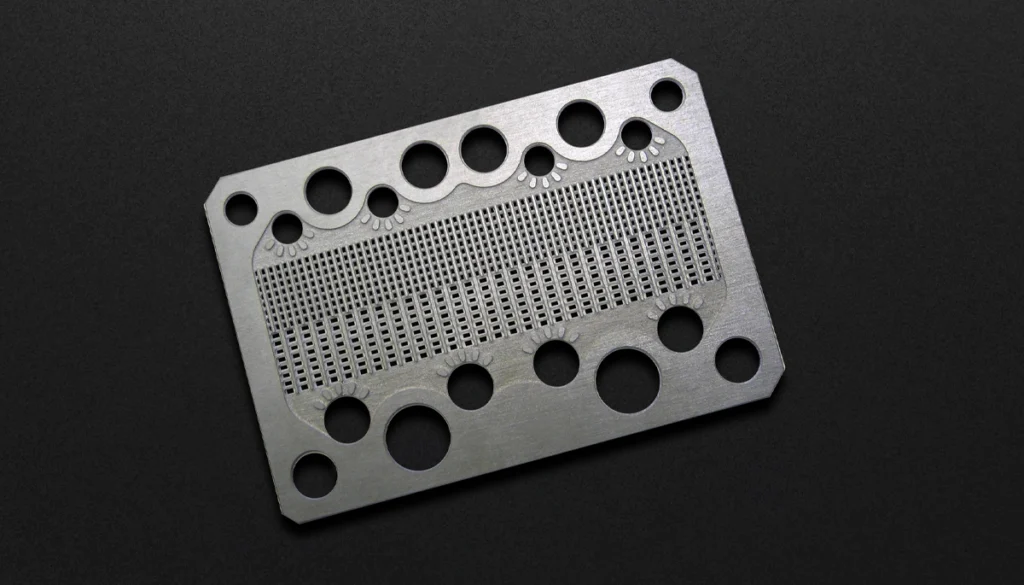

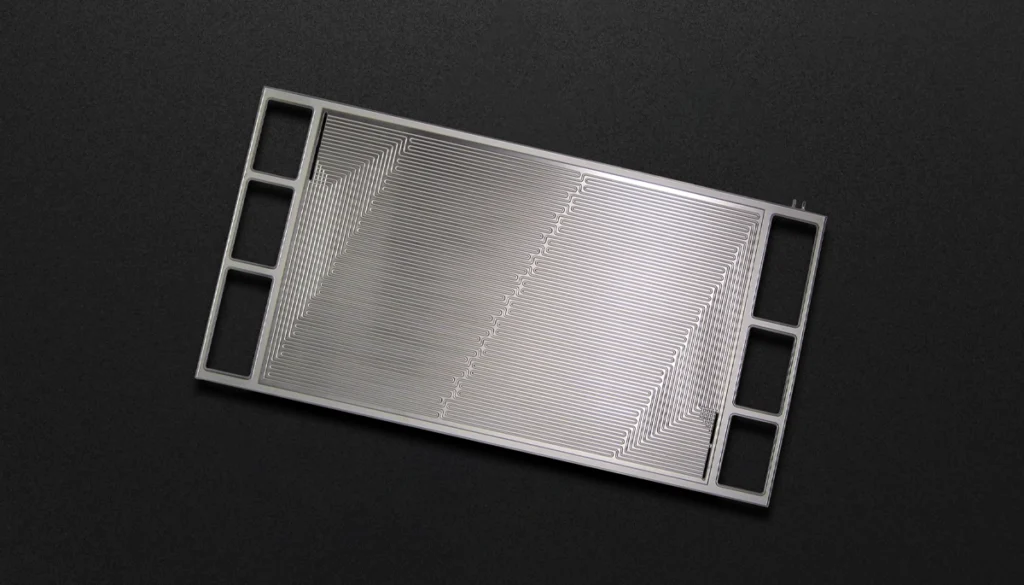

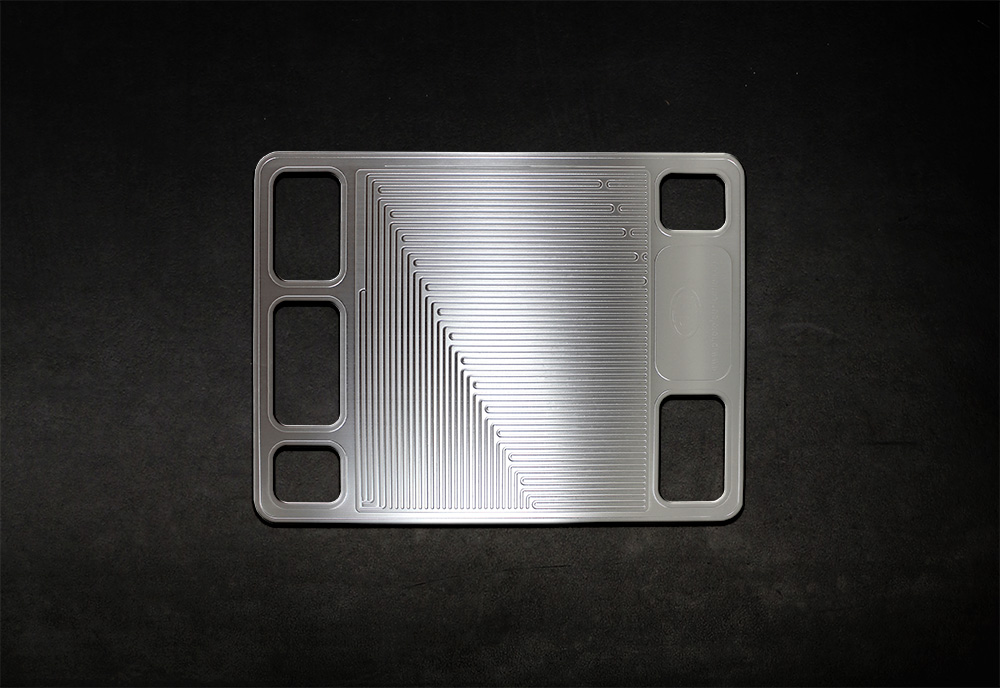

PEI is the world’s leading photochemical etcher of titanium, producing bipolar electrolyzer plates that are an integral part of electrolysis systems used in hydrogen production power plants. Our Engineering, Production, and Quality Assurance teams are experts in optimizing the design and precision manufacturing processes to boost the performance and longevity of every electrolyzer.

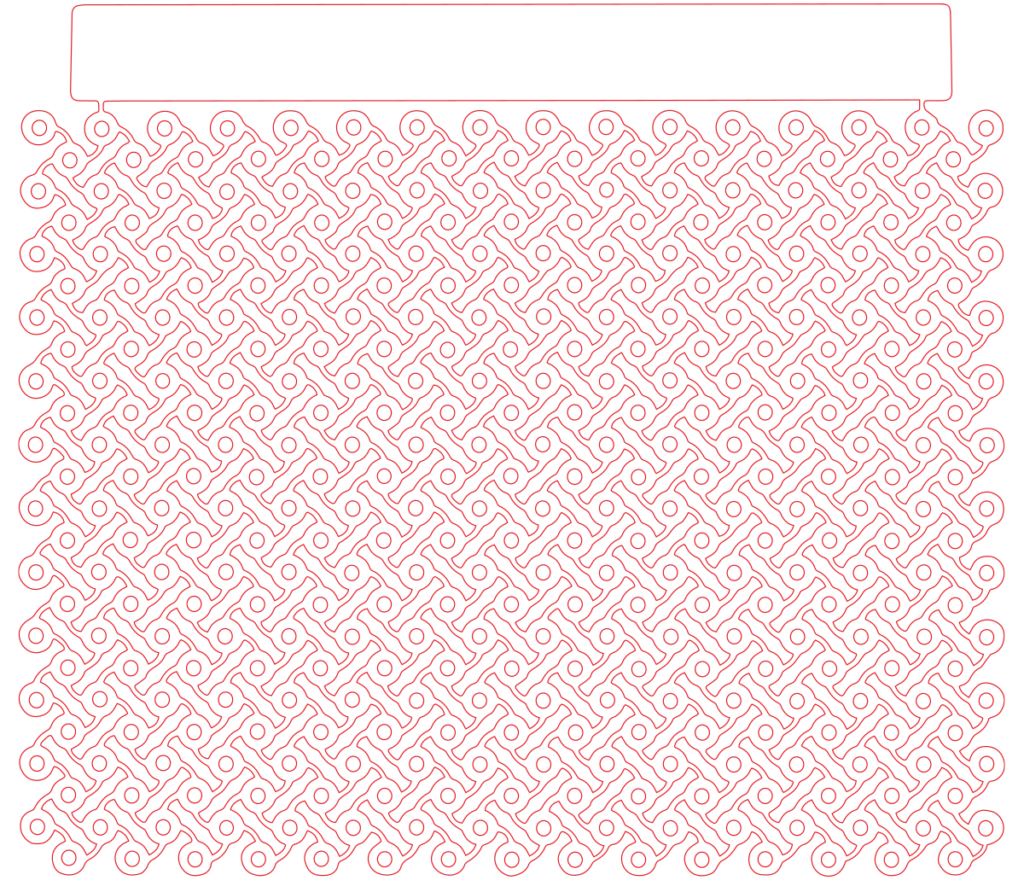

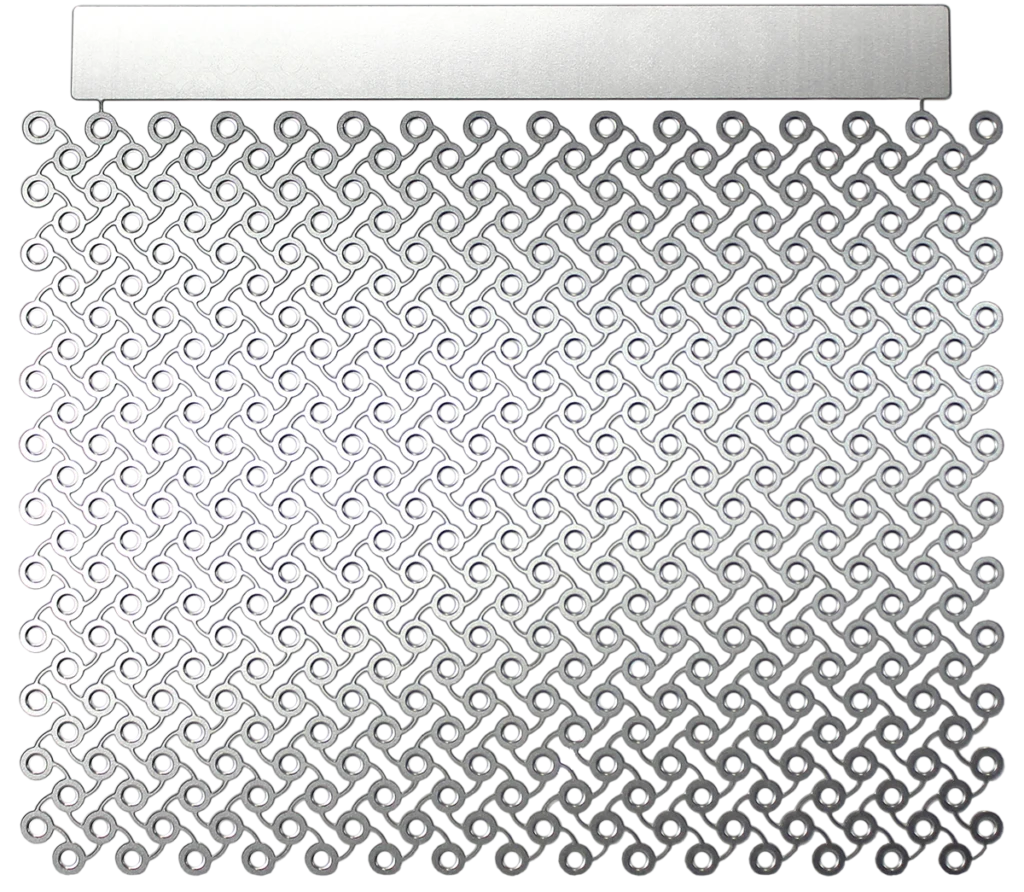

PEI uses photochemical etching to produce the hundreds of essential thin metal parts and components in solar panels, wind turbines, and energy storage systems. PCE is an efficient, cost-effective manufacturing process that creates highly accurate parts with complex patterns and tight tolerances. Our etchers work with a wide range of metals, including titanium, stainless steel, copper, aluminum, and more.

Industries and technologies evolve when people work together to push boundaries and uncover new solutions. For over 50 years, we’ve stood shoulder to shoulder as leading companies across every market sector push forward with revolutionary changes that change the world. We are ready to share and leverage knowledge and expertise to collaborate with our customers for mutual success.

PEI’s long history of meeting and exceeding industry standards and customer expectations began in 1968. For over 50 years, we’ve kept quality assurance at the forefront of our work by training our manufacturing teams, maintaining our equipment, and establishing rigorous internal controls. PEI holds several certifications, including ISO9001:2015, AS9100:2016, and ITAR. We adhere to MIL-STD-45662, MIL-STD-105, and ANSI/ASQC Z1.4 quality standards.