The Automotive sector is one of the most interesting industries in the world today as innovations in engines, interiors, and drivetrains come to life at a rapid pace. PEI’s decades of experience and expertise across the sector make it a willing partner, ready to evolve with the latest changes while using photochemical etching to deliver precise metal parts and components.

Decades of expertise in precision manufacturing across our entire precision advanced manufacturing plant enables us to deliver metal parts and components used in mechanical and decorative applications.

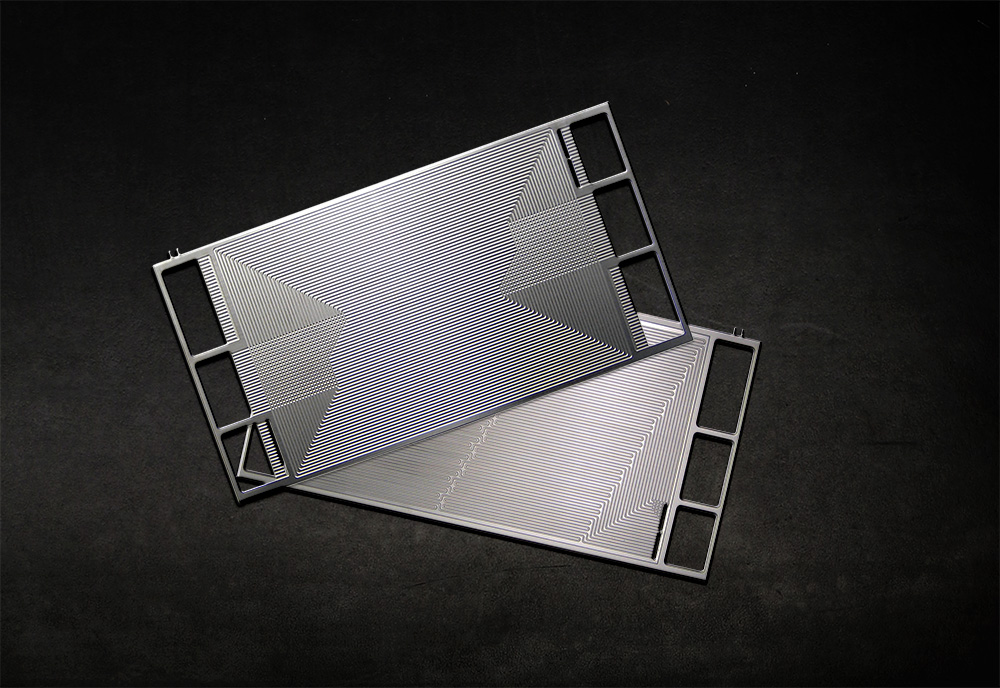

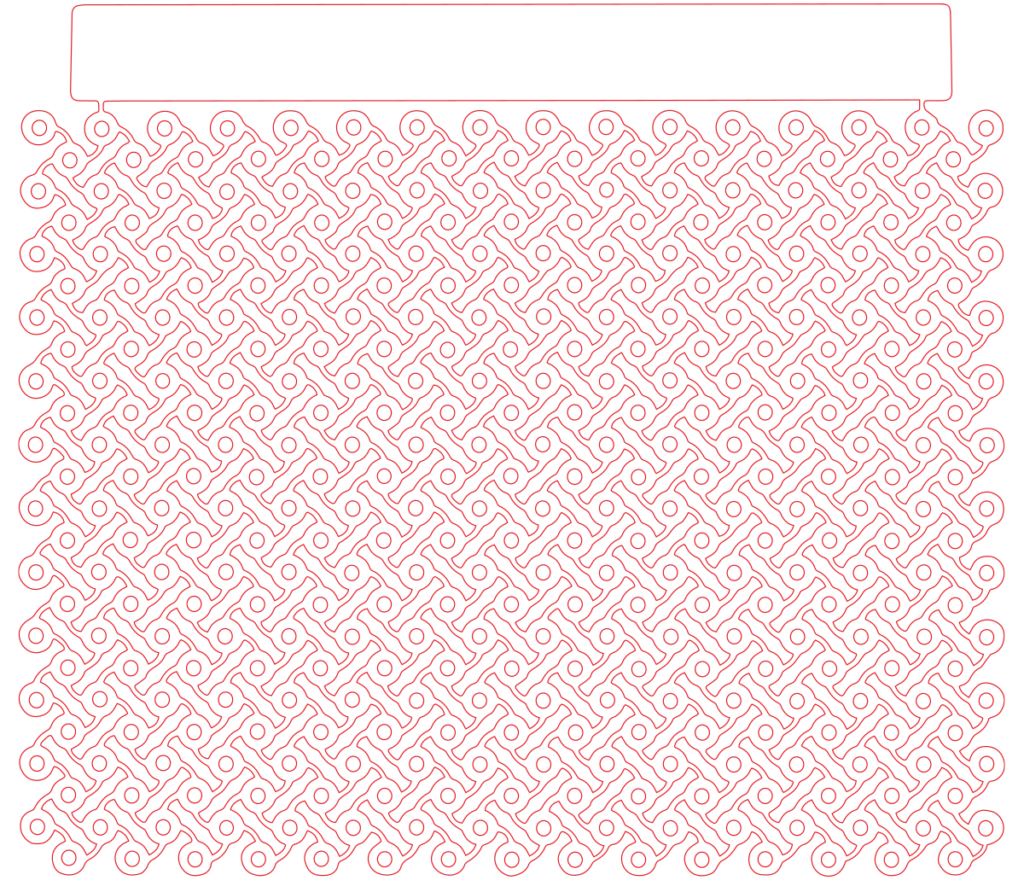

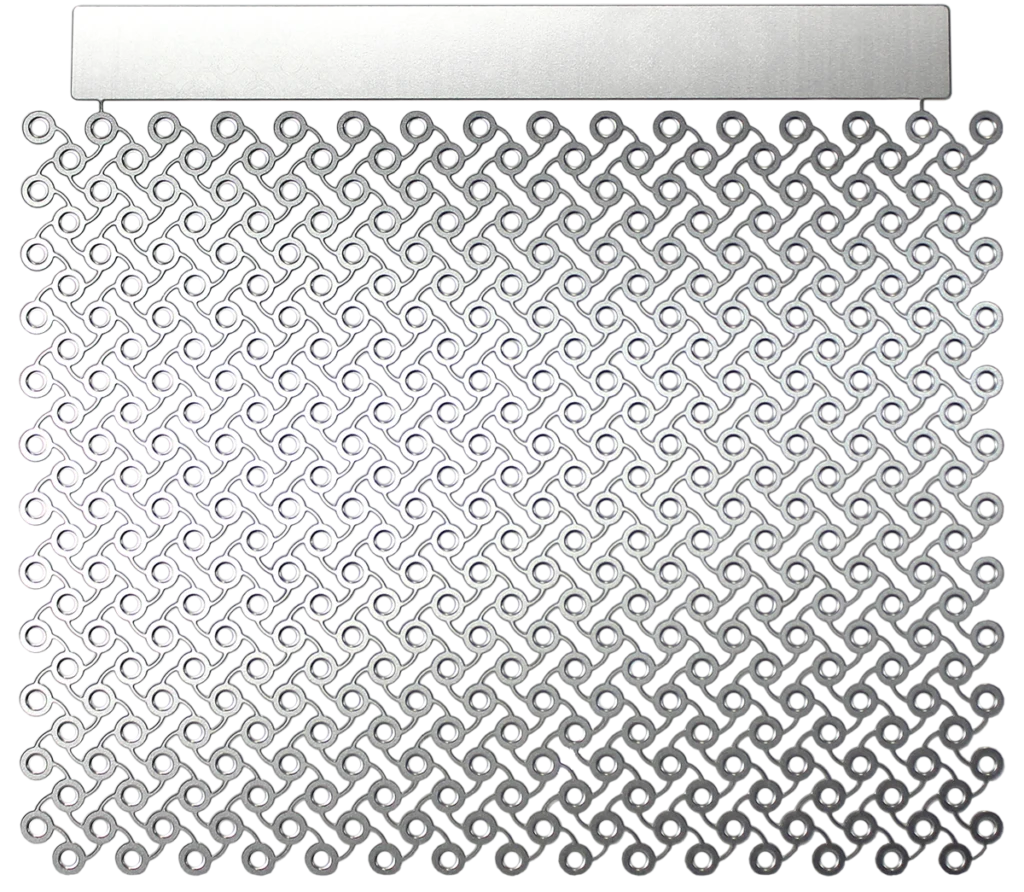

PEI fabricates parts and components using photochemical etching (also known as precision chemical machining, chemical blanking, and photochemical machining). PCE allows for the production of parts from 0.0005 in. (0,0127mm) to 0.1250 in. (3.175mm) thick, which is essential as automotive manufacturers look to reduce the weight of parts while maintaining strength and durability.

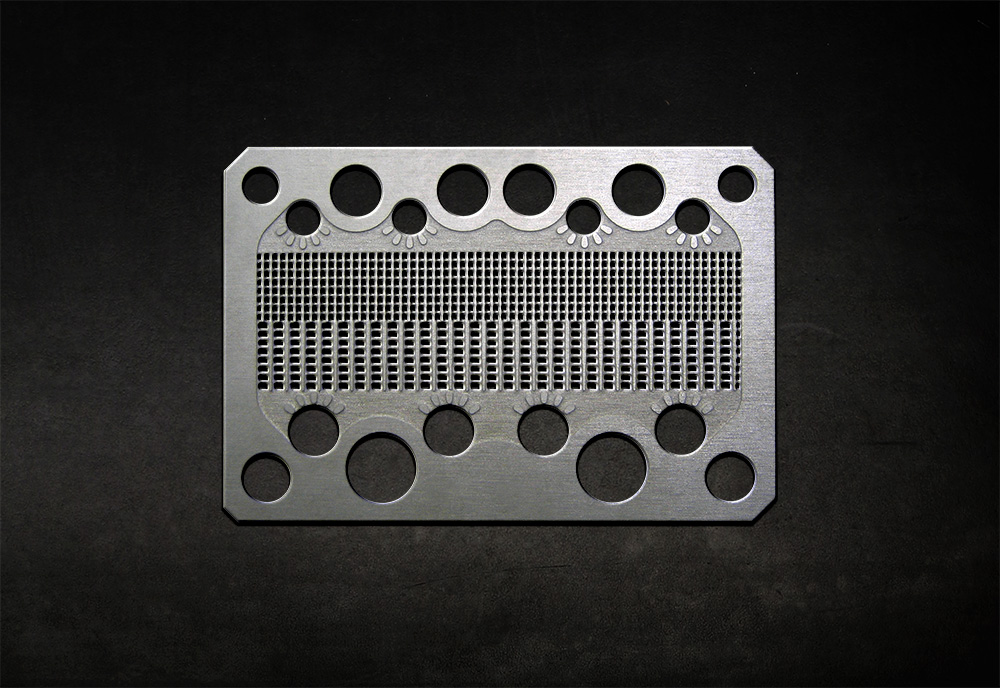

Leading automotive manufacturers tap us to deliver fuel injection screens, brackets, metal gaskets, logo plates, speaker grills, and engine subcomponents like stators, rotors, fuel cells, and more. We’re well-versed in working with various metals, including titanium, stainless steel, aluminum, brass, and more.

Post fabrication, PEI’s list of value-added services includes assembly and finishing to ensure our customers have the exact part ready to install. We strive to deliver excellence at every stage of the process to make your business shine.

Industries and technologies evolve when people work together to push boundaries and uncover new solutions. For over 50 years, we’ve stood shoulder to shoulder as leading companies across every market sector push forward with revolutionary changes that change the world. We are ready to share and leverage knowledge and expertise to collaborate with our customers for mutual success.

PEI’s long history of meeting and exceeding industry standards and customer expectations began in 1968. For over 50 years, we’ve kept quality assurance at the forefront of our work by training our manufacturing teams, maintaining our equipment, and establishing rigorous internal controls. PEI holds several certifications, including ISO9001:2015, AS9100:2016, and ITAR. We adhere to MIL-STD-45662, MIL-STD-105, and ANSI/ASQC Z1.4 quality standards.