Electromagnetic interference (EMI) and radio frequency interference (RFI) can wreak havoc on electronic devices and systems, causing malfunctions and disruptions to compliance issues.

As our world becomes increasingly interconnected, shielding against these interferences has become more critical than ever to ensure electronic device performance, reliability, and compliance across industries.

PEI is a leader in precision manufacturing for EMI/RFI shielding components, boasting decades of experience and a daily dedication to perfection. We stand shoulder to shoulder with our technology partners, delivering precision metal parts and components used by industry-leading computer, communications, and microelectronics manufacturers.

This article explores how EMI/RFI shielding works, the materials used, and its applications, giving businesses the information they need to make informed decisions about their shielding solutions.

What Is EMI/RFI Shielding?

EMI refers to any electromagnetic frequency within the electromagnetic spectrum that can cause interference in electronic devices. On the other hand, RFI refers to signals within the radio frequency range used for communications. Both forms of interference can cause malfunctions, disruptions, and even physical damage to sensitive electronic components.

Interference can be caused by internal (radiation from devices) and external sources, such as cell phones and power lines.

Electronic devices emit and are affected by electromagnetic radiation, which travels in the form of alternating electric and magnetic waves. Without proper shielding, this radiation can interfere with other devices as an interfering signal, leading to incomplete or disrupted signals.

EMI/RFI shielding acts as a protective barrier, preventing interference and ensuring the reliability and performance of electronic devices.

Shielding effectiveness (SE) is a measure of radiation loss.

The Importance of Shielding Against Electromagnetic Radiation

The technology sector is one of the most dynamic and innovative industries, driving advancements that shape our modern world. In this fast-evolving landscape, shielding against electromagnetic radiation is essential to ensure the integrity and reliability of electronic systems.

Effective shielding not only protects sensitive components from interference but also enhances overall performance and longevity, making it a critical consideration in precision metal manufacturing for high-tech applications.

Unchecked interference can:

- Disrupt electromagnetic signals between devices, leading to incomplete data transmission or operational failures.

- Cause malfunctions in critical systems, potentially compromising safety in industries like aerospace, healthcare, and automotive.

- Affect multifunctional devices such as infotainment systems, where multiple operations rely on seamless communication.

EMI/RFI shielding helps mitigate these risks and ensures devices perform as intended, even in challenging environments.

How EMI/RFI Shielding Works

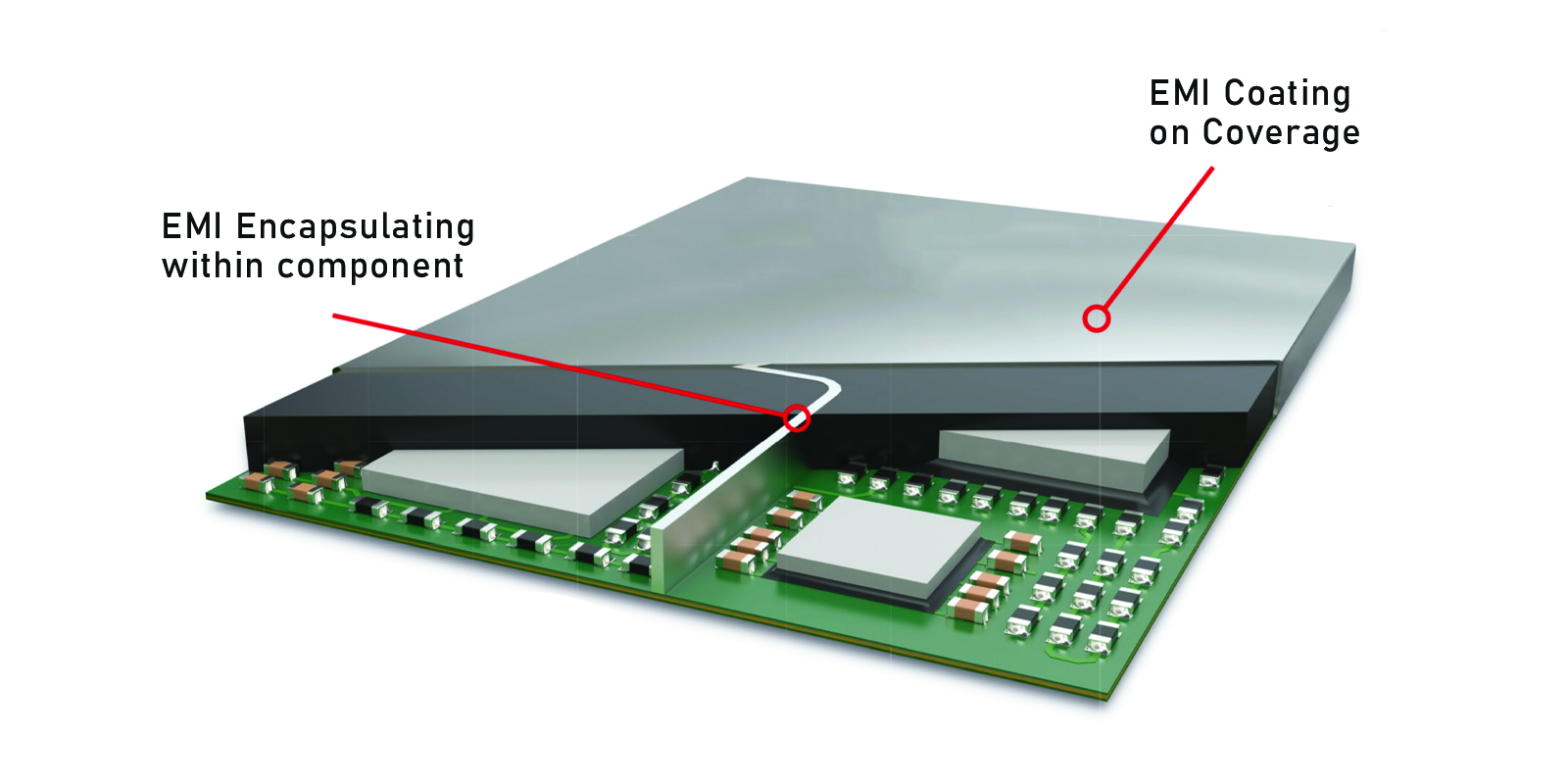

EMI/RFI shielding works by blocking or absorbing electromagnetic waves, preventing them from reaching sensitive components. This is achieved through various methods, including:

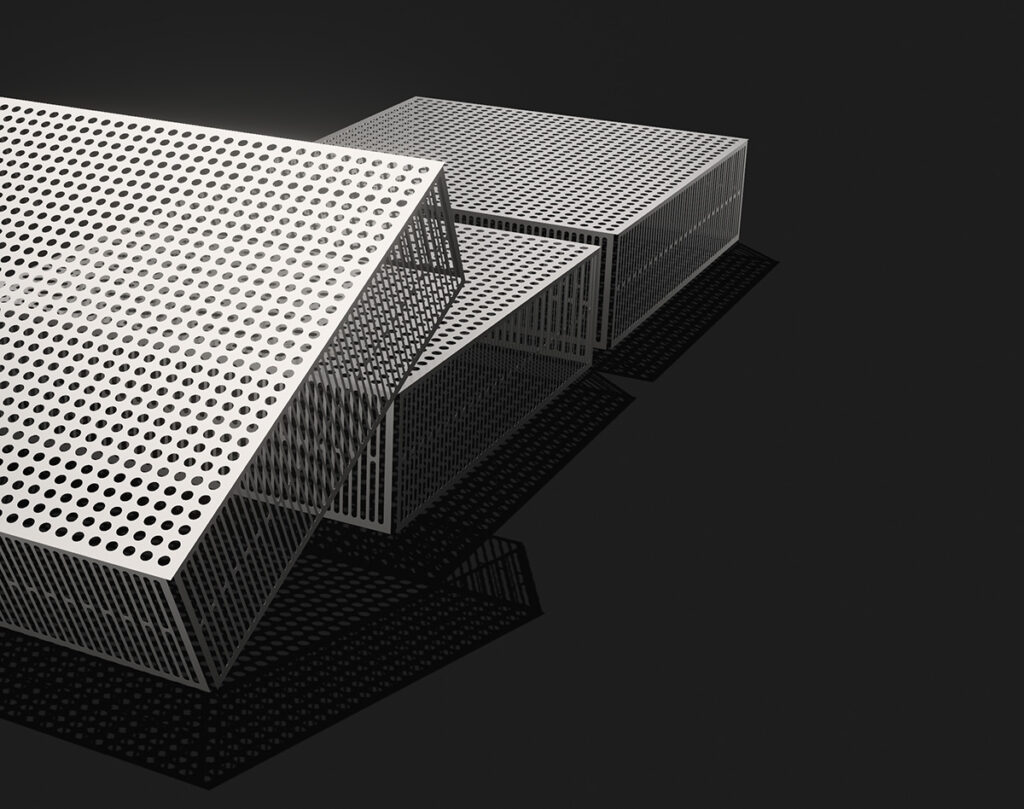

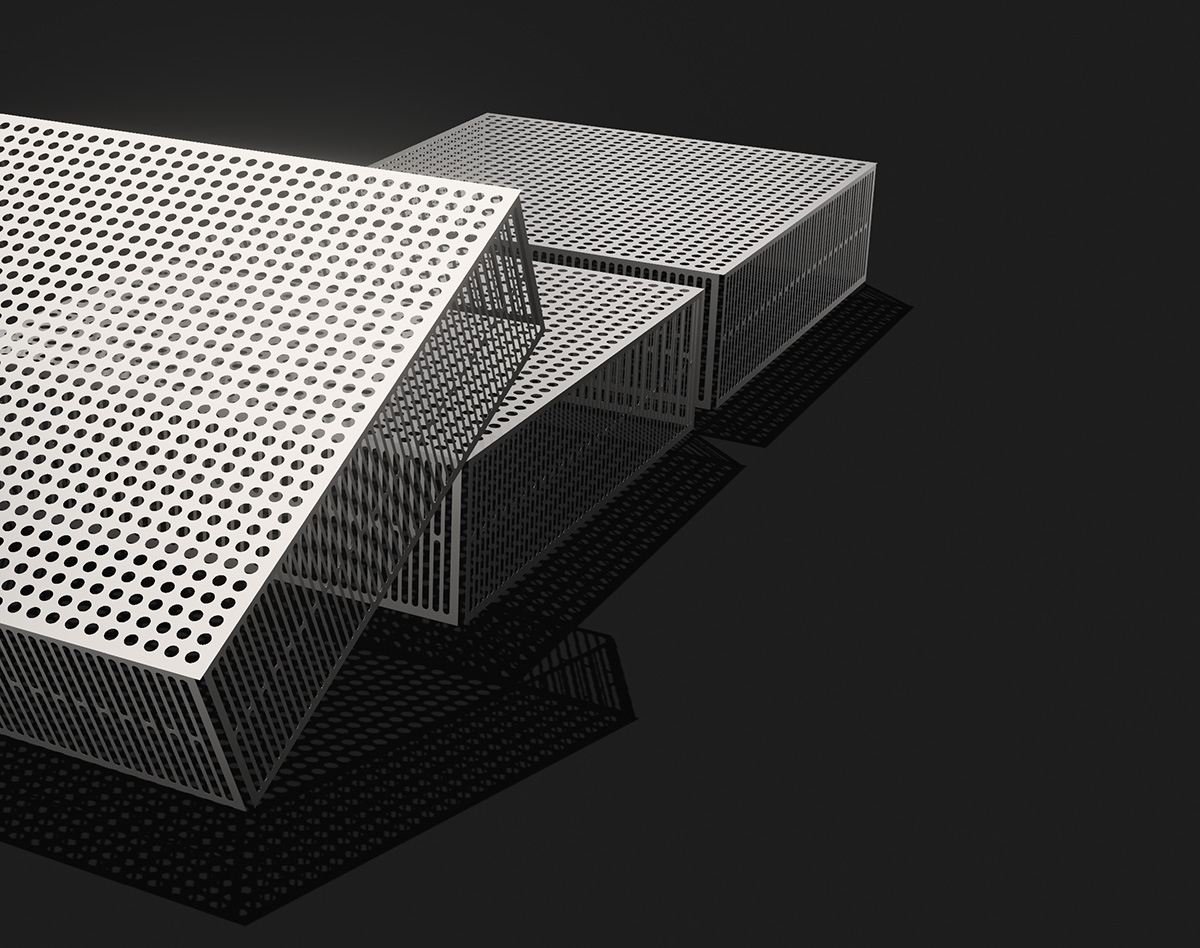

- Enclosures: Metal or composite casings that fully surround sensitive components, creating a conductive barrier against electromagnetic waves.

- Gaskets: Flexible materials with conductive properties that seal gaps in enclosures, ensuring no electromagnetic leakage. Shielding gaskets can be used to seal gaps and prevent electromagnetic emissions.

- Shielding Components: Custom-designed parts that address specific areas of vulnerability, minimizing the entry or escape of electromagnetic interference.

- Conductive tapes: Conductive tapes play a vital role in EMI/RFI shielding by providing an effective barrier against electromagnetic and radio frequency interference.

By combining these elements, shielding solutions create a controlled environment for electronic devices free from disruptive electromagnetic radiation.

Did you know that cleanliness and packaging can affect the quality and performance of EMI shields?

Materials Used for EMI/RFI Shielding

The choice of materials for EMI/RFI shielding is critical to ensuring effectiveness and durability. Material selection depends on factors such as the specific frequency range, durability requirements, and environmental considerations, ensuring optimal performance for each application.

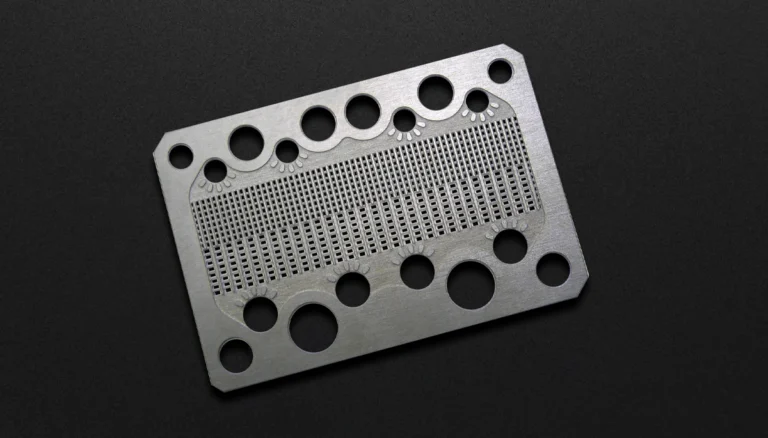

Shielding materials are generally made from conductive materials, such as copper, aluminum, and nickel.

Common materials include:

- Copper: Renowned for its excellent conductivity and ability to shield against a broad range of frequencies.

- Aluminum: Lightweight and cost-effective, aluminum provides good conductivity and corrosion resistance.

- Stainless Steel: Offers durability and strength, ideal for environments requiring mechanical resilience.

- Nickel Alloys: Combines high conductivity with superior corrosion resistance, suitable for harsh conditions.

PEI is the world’s leader in the etching of titanium and specializes in a handful of other metals, including stainless steel, copper, nickel silver, and molybdenum.

We’re also one of the few photochemical machining companies that can etch beryllium copper. Renowned for its exceptional hardness, strength, and thermal and electrical conductivity, this metal requires extra care because of the serious health hazards posed by beryllia dust.

Applications of EMI/RFI Shielding Across Industries

EMI/RFI shielding is widely used in the telecommunications, aerospace, automotive, medical, and consumer electronics industries to protect sensitive equipment from electromagnetic interference.

Its applications include shielding enclosures for electronic devices, cable assemblies, and critical components in medical devices and military systems to ensure reliable performance in demanding environments.

The key applications of EMI/RFI shielding include:

- Electronics: Shielding protects sensitive components in consumer devices, medical equipment, and industrial systems, ensuring accurate functionality and reducing interference.

- Aerospace & Defense: High-stakes environments demand reliable communication and system performance, making shielding essential for aircraft, satellites, and military equipment.

- Telecommunications: Shielding ensures signal integrity in both wireless and wired systems, supporting uninterrupted communication in an interconnected world.

- Automotive: Modern vehicles rely on shielding to protect critical systems, such as infotainment, navigation, and advanced driver assistance systems (ADAS), from electromagnetic interference.

- Medical: Medical devices require special consideration for EMI/RFI shielding due to their critical nature.

At PEI, we’re a leading supplier of mission-critical precision thin metal parts used in military and consumer microwave applications. We have a decades-long history of supplying the microwave industry with microwave circuits, electrical contacts, EMI shields, RF Shields, step lids, flat lids, gaskets, face plates, screens, and dozens of additional precision-etched metal components.

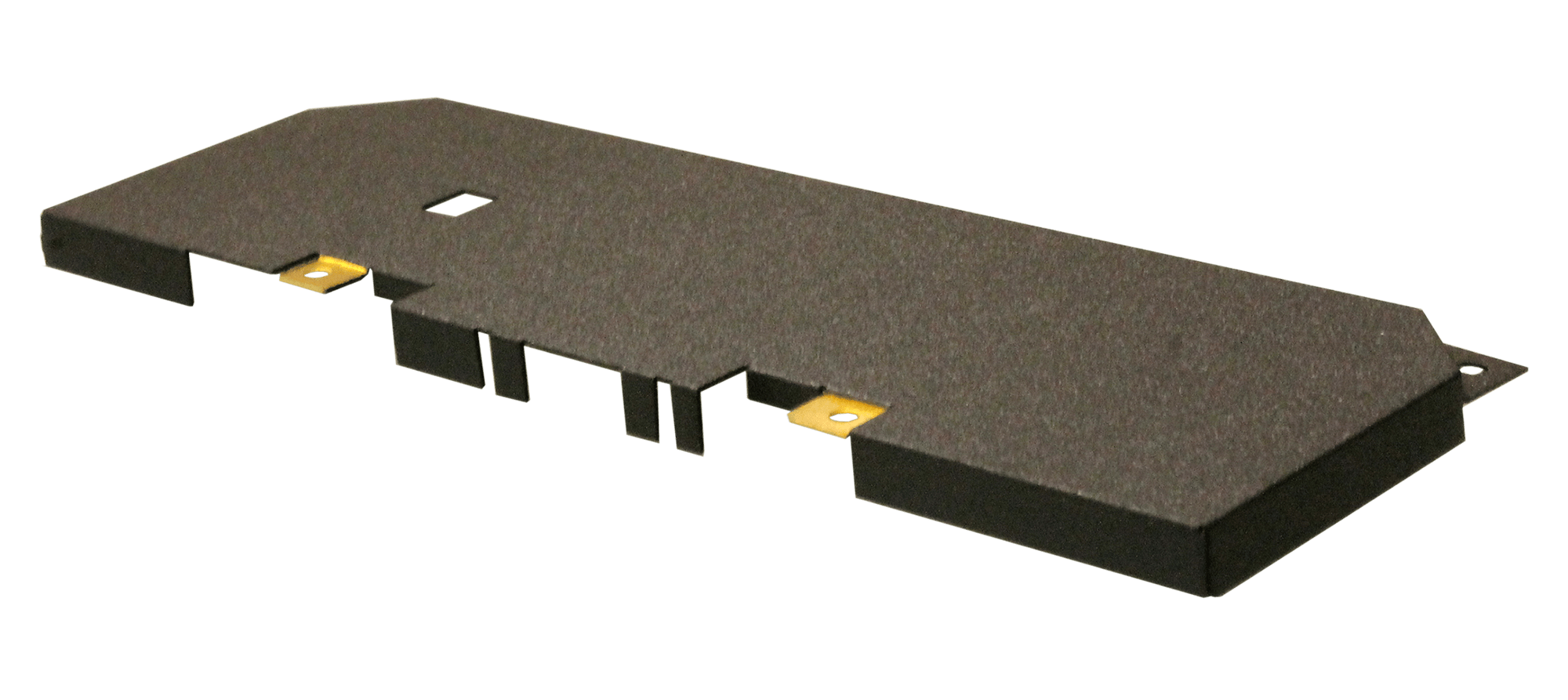

We feature a patented line of EMI/RF shielding cans and an easy-access removable cover designed to protect components from radio frequency/electromagnetic interference and environmental hazards, as well as to provide electrical grounding. Our unique design lets users quickly and easily replace or repair internal components without damaging the shield.

PEI’s Expertise in EMI/RFI Shielding Components

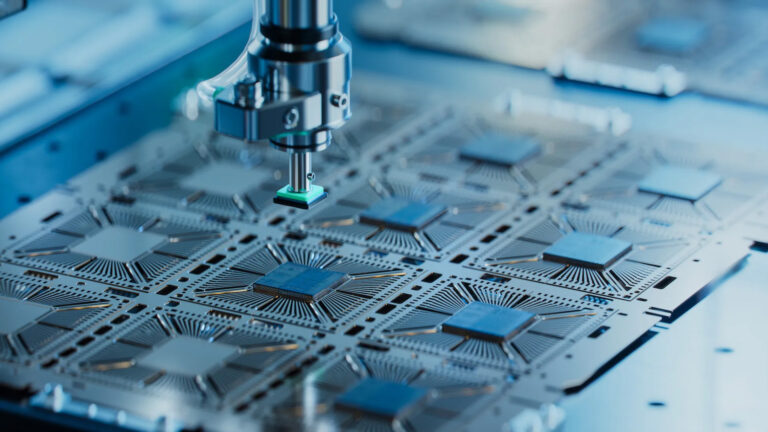

The PEI legacy of precision, dependability, and on-time delivery is essential when serving the technology sector, especially as the demand for faster, safer, and more reliable solutions. We are experts in photochemical machining, which creates highly precise thin metal parts.

Our innovative PCM process allows for the production of parts from 0.0005 in. (0,0127mm) to 0.1250 in. (3.175mm) thick, which is essential as technology manufacturers look to reduce the weight of parts while maintaining strength and durability.

Our EMI and RF shield cans feature a patented, easy-access removable cover. This unique design allows users to quickly and easily replace or repair internal components without damaging the surrounding shield.

Here’s what sets PEI apart:

Precision Through Precision Chemical Machining: We specialize in photochemical etching, a cutting-edge manufacturing process that produces intricate, high-precision shielding components with tight tolerances. This process ensures superior performance for EMI/RFI applications, enabling even the most complex designs to meet exacting standards.

Customization to Your Needs: We deliver fully customized shielding solutions tailored to the unique requirements of each application. Whether it’s unique dimensions, complex geometries, or specific material needs, our experienced team ensures every product aligns with client specifications.

Experience Across Industries: With decades of expertise, we’ve served industries such as aerospace, medical, telecommunications, and electronics. This extensive experience equips our team with a deep understanding of each sector’s unique challenges and demands.

High-Quality Materials and Manufacturing: We’re material selection specialists experienced in premium materials like copper, aluminum, and nickel alloys to ensure optimal conductivity, durability, and performance. Our stringent quality controls guarantee that every component meets the highest standards.

Rapid Prototyping and Scalability: From prototypes to large-scale production, our efficient processes ensure quick turnarounds without compromising quality. This enables clients to stay on schedule while maintaining superior results.

Regulatory Compliance: Our shielding solutions comply with stringent industry standards, ensuring reliable performance and adherence to regulatory requirements. This commitment to compliance makes PEI a trusted partner for high-stakes applications.

Work with the Masters of Microelectronics

As technology advances at an unprecedented rate, EMI/RFI shielding is becoming an even more critical component of device design to prevent electromagnetic interference and ensure the proper functioning of electronic devices.

From consumer electronics to aerospace systems, reliable shielding solutions are critical to reliable performance and regulatory compliance across various leading industries.

As industry leaders in precision chemical machining, the team at PEI boasts a 50-plus-year history of producing accurate, durable, and dependable metal parts used by the world’s leading industries.

With our proven machining process, we can deliver high-quality, accurate EMI/RFI shielding components with unmatched performance and reliability. Our EMI and RF shield cans feature a patented, easy-access removable cover. This unique design allows users to quickly and easily replace or repair internal components without damaging the surrounding shield.

If you’re looking for proven shielding solutions used by industry-leading computer, communications, and microelectronics manufacturers, we can help. Our expert team of engineers, manufacturers, and quality assurance professionals are ready to answer any challenge.