As the global demand for renewable energy sources continues to grow, green hydrogen has emerged as a key fuel in the transition toward sustainable power. With the potential to decarbonize a range of leading industries, hydrogen, especially green hydrogen, has the versatility needed to drive the next wave of clean energy solutions.

PEM electrolyzers (Proton Exchange Membrane electrolyzers) are a critical part of this process, playing an essential role in hydrogen production by facilitating the hydrogen evolution reaction that separates hydrogen from water to form hydrogen gas. According to the International Renewable Energy Agency (IRENA), the demand for hydrogen is only set to grow, with the expanding hydrogen economy set to be instrumental in meeting the world’s clean energy targets. With hydrogen being the missing piece of the clean energy puzzle, the selection of reliable, efficient PEM electrolyzer manufacturers is crucial for a smooth and safe transition.

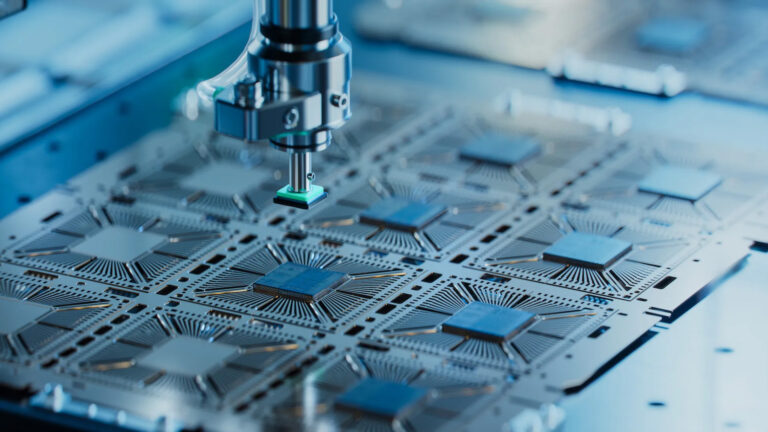

One company leading this charge is Photofabrication Engineering, Inc. (PEI). As a global leader in precision chemical machining, we’ve built a reputation for delivering precision-engineered components optimized for hydrogen-related applications. Our innovative machining processes produce precision components that are critical to high-performance PEM electrolyzers, providing the foundation for efficient and reliable hydrogen production systems.

In this article, we explore the importance of finding the right manufacturer, what to consider when selecting a manufacturer, and the critical role of precision engineering in PEM electrolyzer production.

The Importance of Selecting Reliable Manufacturers in the Growing Hydrogen Economy

In the rapidly evolving hydrogen economy, selecting a reliable manufacturer for PEM electrolyzers is vital for ensuring high-quality, compliant systems that can meet the rigorous demands of renewable energy production.

According to The Hydrogen Council, the global voice of clean hydrogen action, investments in hydrogen solutions must prioritize reliability and performance. A key callout from their 2024 Hydrogen Insights report is that collaborating with reputable manufacturers is essential to meeting regulatory standards, achieving high energy efficiency, and securing long-term project outcomes.

To ensure that PEM electrolyzers can support energy transition goals, it’s critical to evaluate manufacturers based on their technological strengths, customization options, and cost efficiency, among other factors. Each of these considerations will impact the longevity, maintenance, and overall return on investment (ROI) of a hydrogen project.

Key Considerations for Selecting a PEM Electrolyzer Manufacturer

1. Technological Expertise and Innovation

The technology behind PEM electrolyzers is complex, demanding cutting-edge innovation to achieve high efficiency and output. Choosing a manufacturer that prioritizes PEM water electrolysis technology is essential for obtaining the most advanced systems. Manufacturers who invest in advanced electrolysis technology—whether through high-efficiency catalysts, robust membrane designs, efficient gas separation mechanisms, or optimizing both the oxygen evolution reaction and electrical energy usage—deliver systems that meet production goals while minimizing energy consumption.

With our commitment to precision machining, PEI consistently produces components with the exact tolerances and precise material compositions required to optimize the operation of electrolyzers. Our engineers leverage the power of technology and decades of experience to ensure each design and plan will deliver the expected results, whether the application involves PEM electrolyzers or solid polymer electrolyte membrane systems.

2. Material Selection and Durability

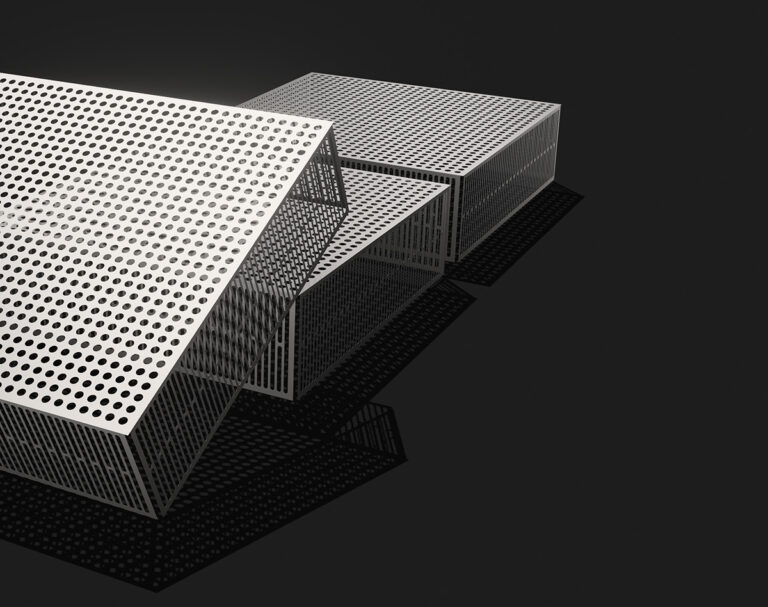

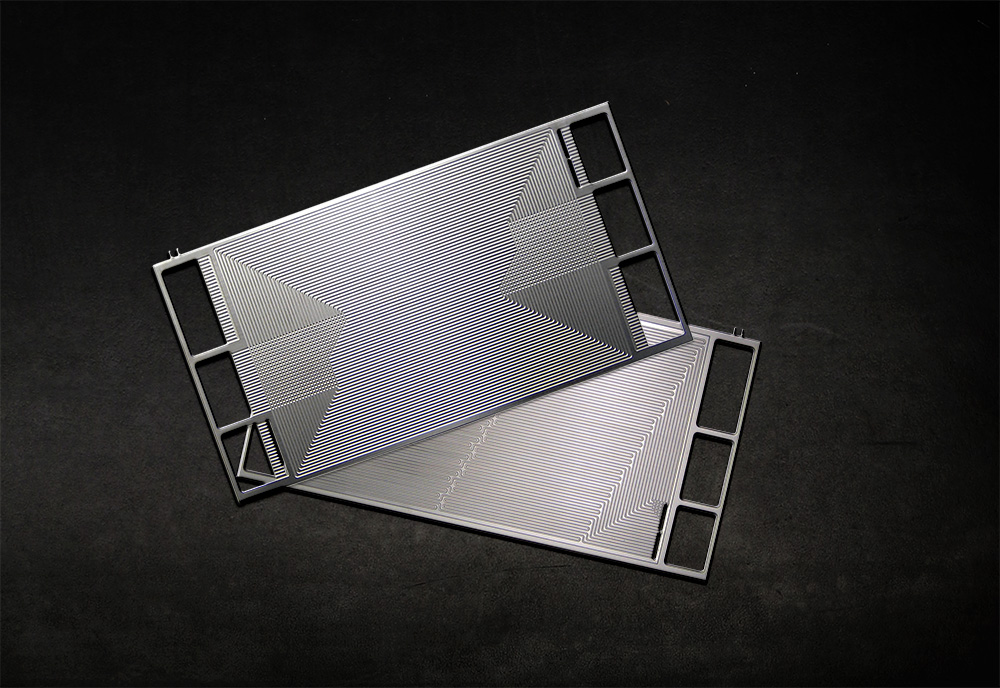

The performance of a PEM electrolyzer depends on the durability and quality of its components. Choosing a manufacturer that prioritizes high-quality materials for critical parts, such as catalysts, membranes, and metal separators, ensures long-term system stability and efficiency. Corrosion resistance, electrical conductivity, and durability are all material characteristics that play a significant role in electrolyzer performance.

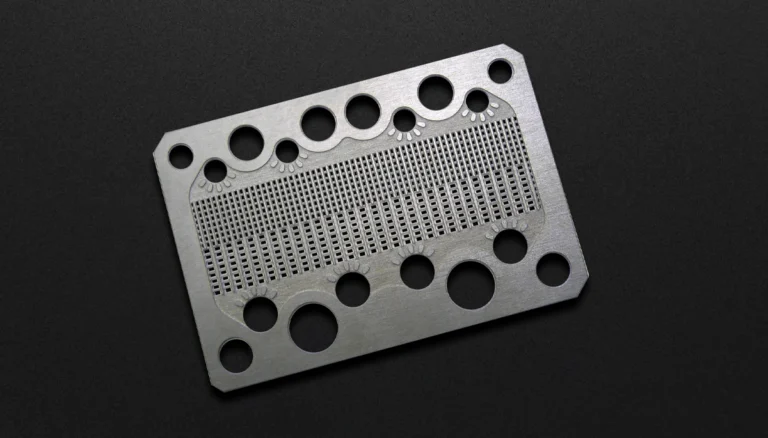

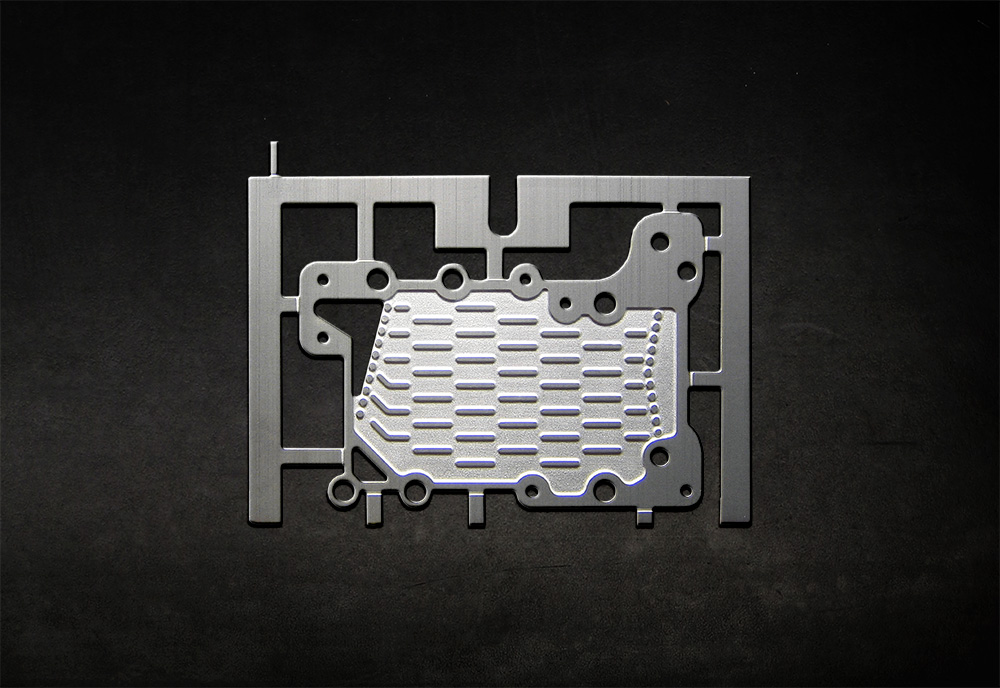

PEI’s expertise in precision metal fabrication is what enables us to deliver components with the exact specifications needed to perform in even the harshest operating conditions for longer. Our etchers work with a wide range of metals, including titanium, stainless steel, copper, aluminum, and more, producing precision electrolyzers that require minimal maintenance and ensure consistent hydrogen production.

3. Customization and Scalability

Hydrogen projects come in all sizes and complexities, and a one-size-fits-all approach rarely meets unique operational needs. Manufacturers offering customization and scalable production options allow clients to tailor PEM electrolyzers to fit specific project requirements, whether they’re small pilot programs or large-scale industrial installations.

Customization can extend to anything from stack configurations and material specifications to output capacities, while scalability ensures that manufacturers can meet increasing demands of hydrogen produced as projects expand. With custom fabrication services like those at PEI, companies gain access to components that match their precise specifications, enhancing system integration and project flexibility.

4. Regulatory Compliance and Certifications

In an industry focused on sustainability and safety, regulatory compliance and certifications are paramount. PEM electrolyzer manufacturers must adhere to stringent safety, environmental, and quality standards, including ISO certifications and green energy certifications. Compliance not only ensures safe operation but also confirms that the electrolyzers contribute to sustainable energy practices. A manufacturer’s commitment to regulatory standards is a strong indicator of product quality and reliability.

By partnering with companies that are committed to quality, clients can confidently deploy electrolyzers that meet both operational needs and regulatory requirements. Dedicated to delivering the highest levels of quality and safety, PEI is ISO9001:2015 and AS9100:2016 certified and ITAR compliant, showcasing our standing as one of the leading precision metal manufacturers.

5. Cost and ROI

When evaluating PEM electrolyzer manufacturers, it’s essential to assess both initial investment costs and total cost of ownership (TCO), which includes maintenance, efficiency, and durability considerations.

Higher-quality systems may involve greater upfront costs but often lead to reduced operational expenses over time. An effective PEM electrolyzer minimizes energy consumption, reduces downtime, and requires fewer repairs—all of which contribute to a higher return on investment. Partnering with a reputable manufacturer ensures that clients receive systems with optimal cost structures that support long-term financial sustainability.

When you work with PEI, you’re working with a team that prioritizes efficiency and reliability in our precision parts. Our proven approach significantly influences the overall economic viability of hydrogen projects, delivering stronger ROI and a better bottom line.

The Role of Precision Engineering in PEM Electrolyzer Manufacturing

Precision engineering is critical in the production of PEM electrolyzers, where even the smallest inconsistencies can affect system efficiency and durability. Electrolyzers require components with exact specifications to function at peak performance, making precision machining essential to reliable hydrogen production.

PEI’s dedication to precision engineering ensures that each electrolyzer component, from electrolyzer stacks to the balance of plant (BoP), meets stringent accuracy requirements. High-quality, precisely fabricated components contribute to the electrolyzer’s stability, enabling it to produce hydrogen consistently and at scale.

At PEI, we apply specialized precision machining techniques to create electrolyzer parts that withstand high pressures, temperatures, and corrosive conditions. By delivering components manufactured with accuracy and durability in mind, we enable clients to achieve efficient hydrogen production while reducing the risk of system failures. With precision-engineered components, PEM electrolyzers can operate reliably over extended periods, providing the performance consistency essential for large-scale hydrogen applications.

Fuelling the Transition to a Sustainable Future

With its potential to replace fossil fuels in various sectors, particularly in industries and applications that are challenging to electrify directly, hydrogen is fuelling the world’s transition to a more sustainable future.

Directly impacting the success and longevity of hydrogen production projects, the selection of a PEM electrolyzer manufacturer has quickly become an incredibly important decision. By evaluating manufacturers on factors like technological innovation, material quality, customization capabilities, regulatory compliance, and cost-effectiveness, you can ensure you’re investing in systems that deliver high performance and efficiency over the long term.

When the mission is to save the world’s environment, precision is the only option. PEI brings decades of experience and industry-leading expertise to take on the challenge every day. With our proven expertise in precision machining and commitment to quality, you get access to reliable, high-performance components that support the complex demands of hydrogen production.

Our precision parts are crucial in applications such as solid oxide fuel cells and solid oxide electrolyzers, supporting advanced solutions in renewable electricity and sustainable hydrogen production.

If you’re looking for expert advice or specialized precision components for hydrogen-related applications, PEI is the trusted partner for achieving optimized performance in PEM electrolyzers. Reach out to our team today to learn more about how we can support your project needs and drive success in your hydrogen production initiatives.