Modern medicine is a wondrous practice, with revolutionary cures and treatments saving lives and improving health outcomes arriving nearly every day. Surgeons and physicians rely on the latest technology to provide expert-level diagnostics, treatment, and procedures.

PEI supports the medical profession with precision parts and components used in MRI machines, medical implants, and surgical tools.

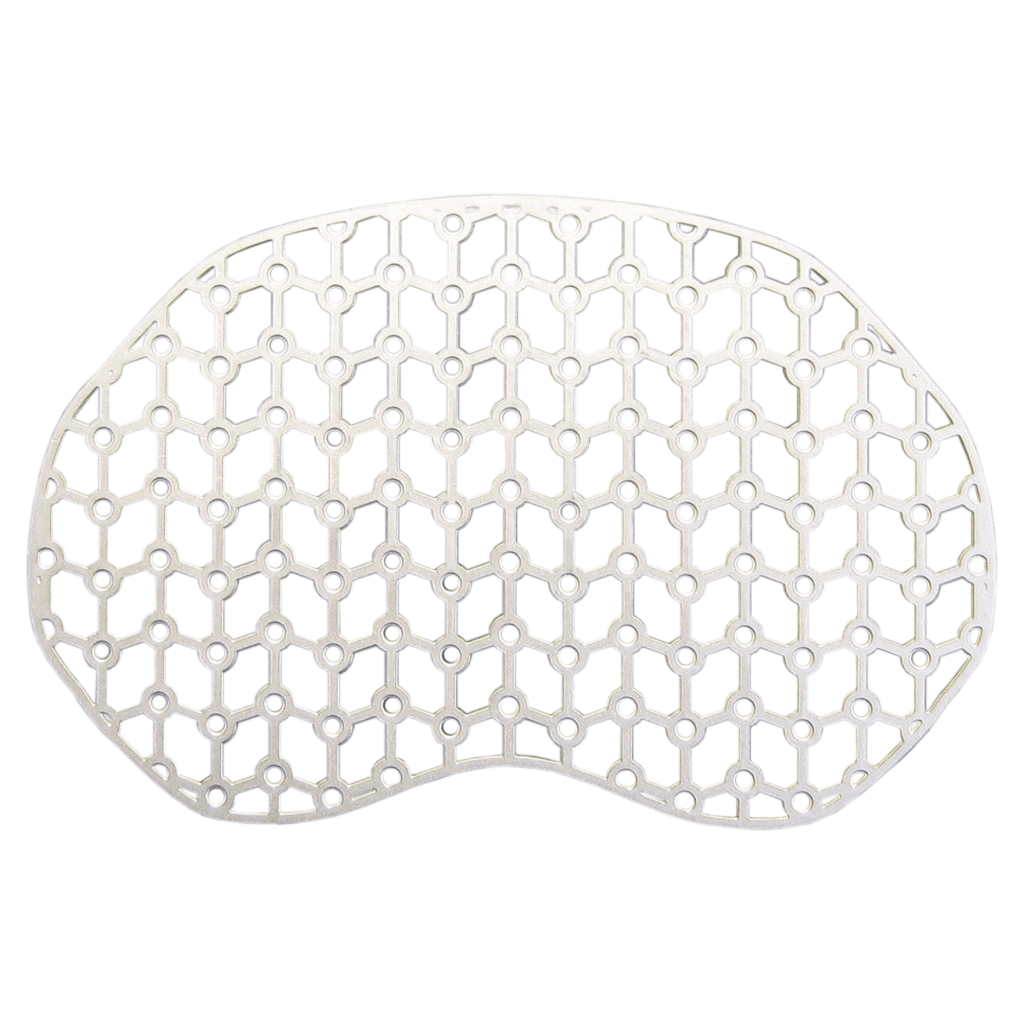

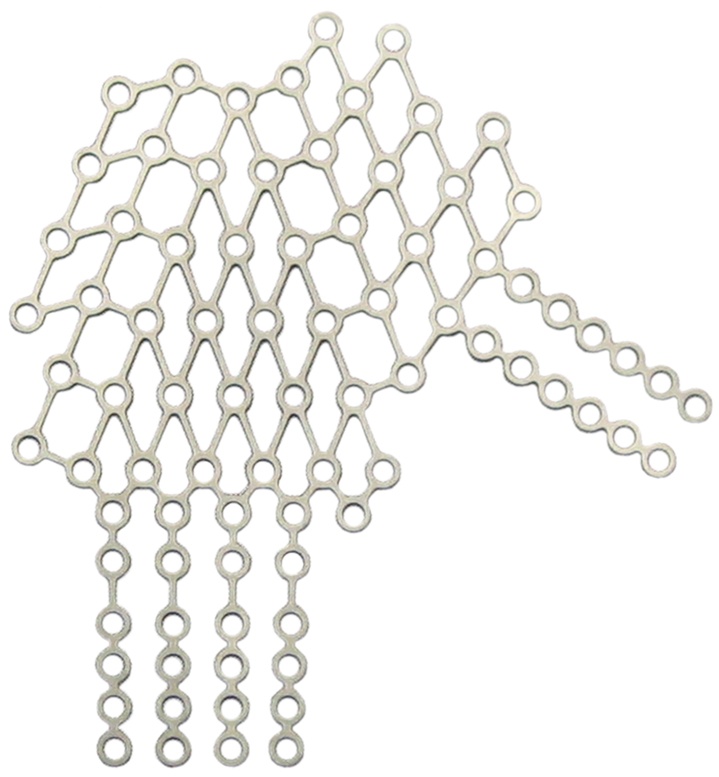

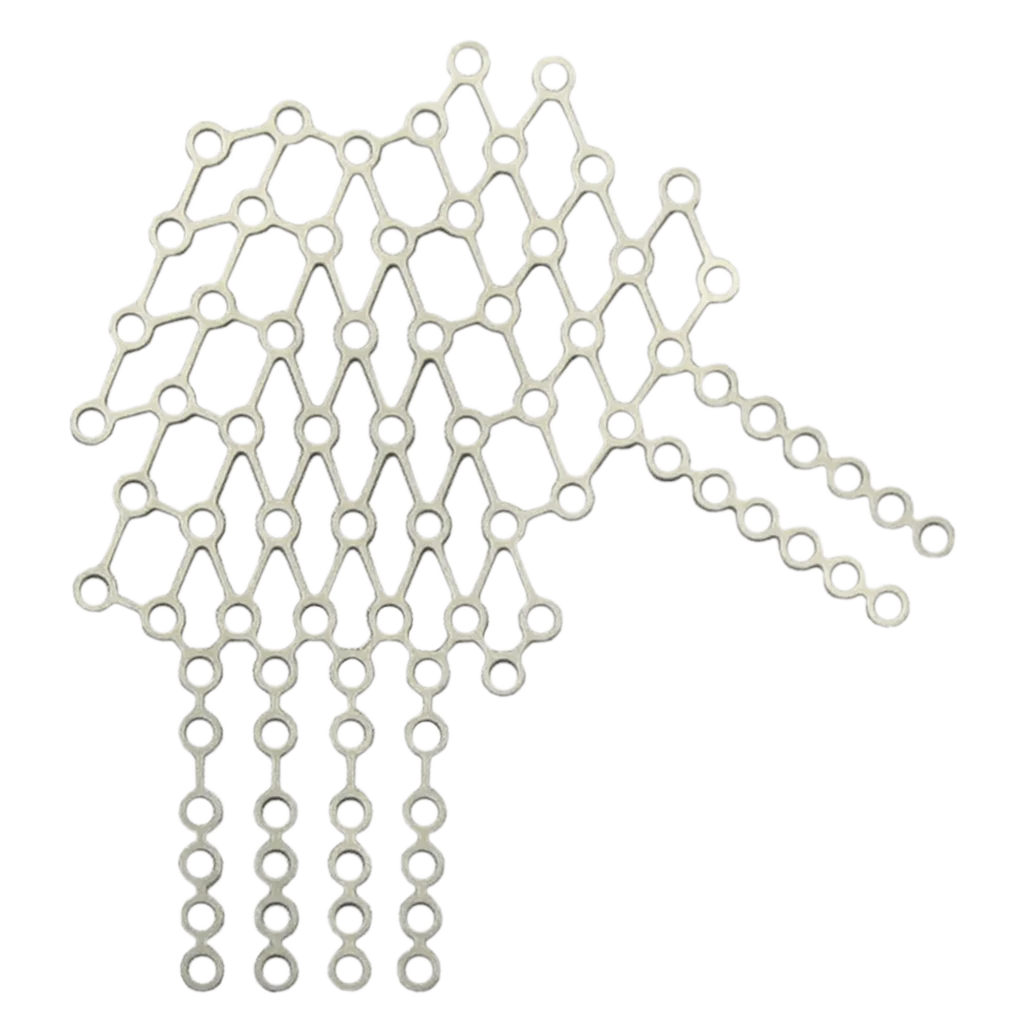

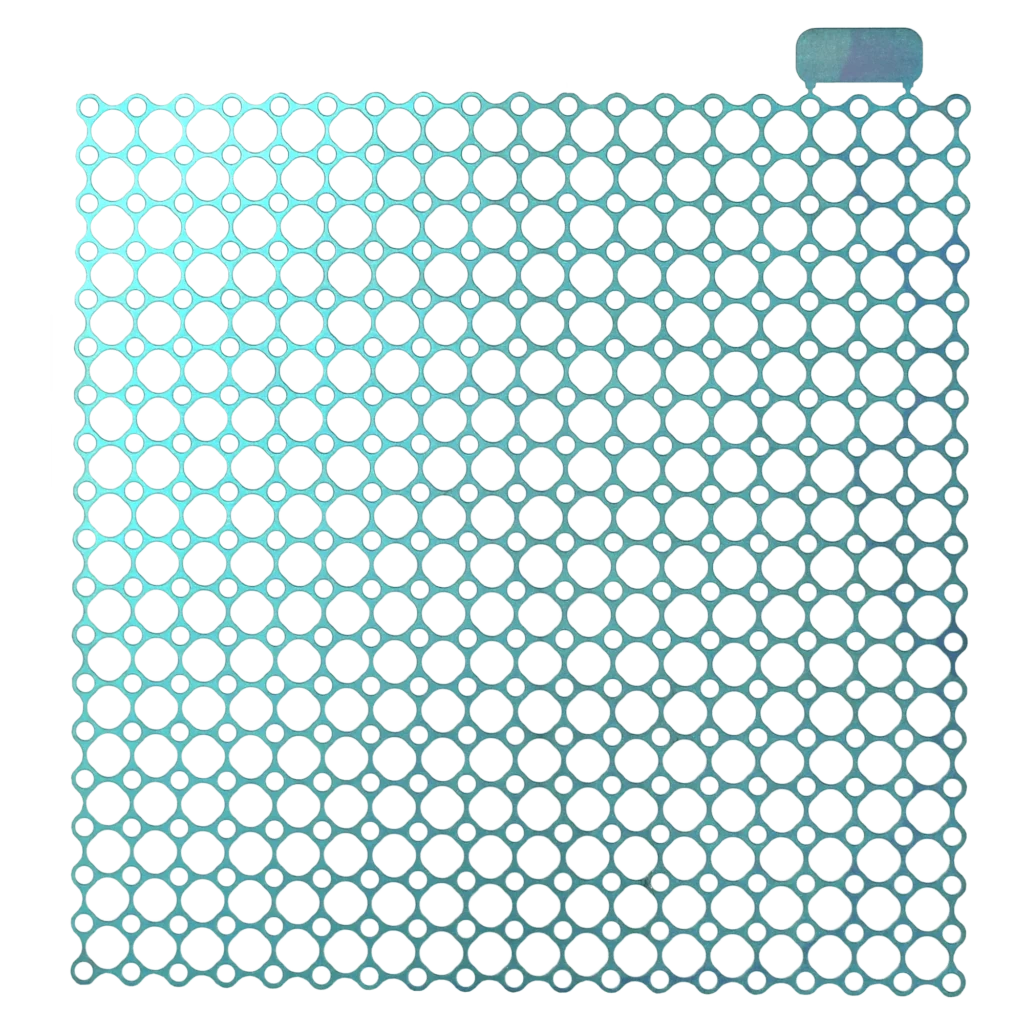

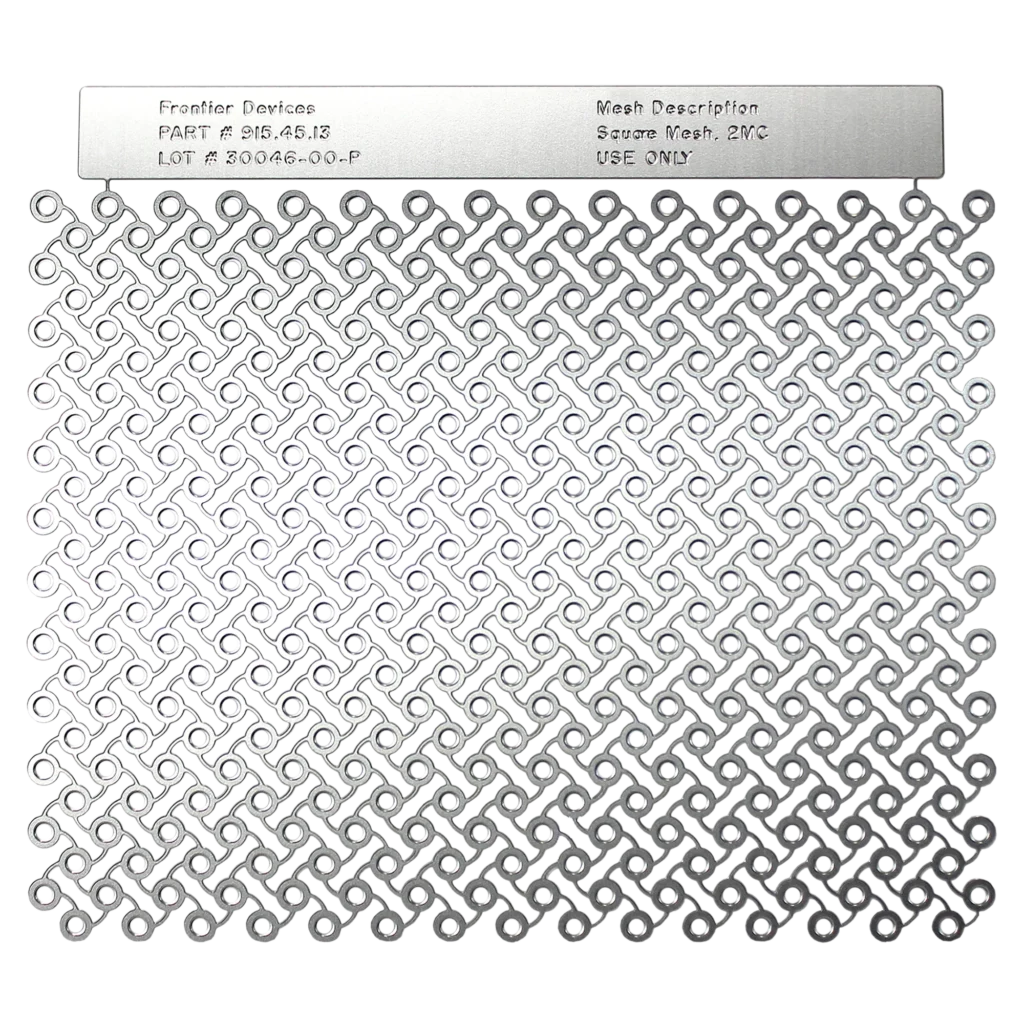

Titanium surgical mesh is a particular area of expertise at PEI. We supply medical companies with custom-fabricated mesh in a wide variety of sizes and shapes with integrated locations for mounting screws and more open space in the mesh for improved weight-to-strength factors.

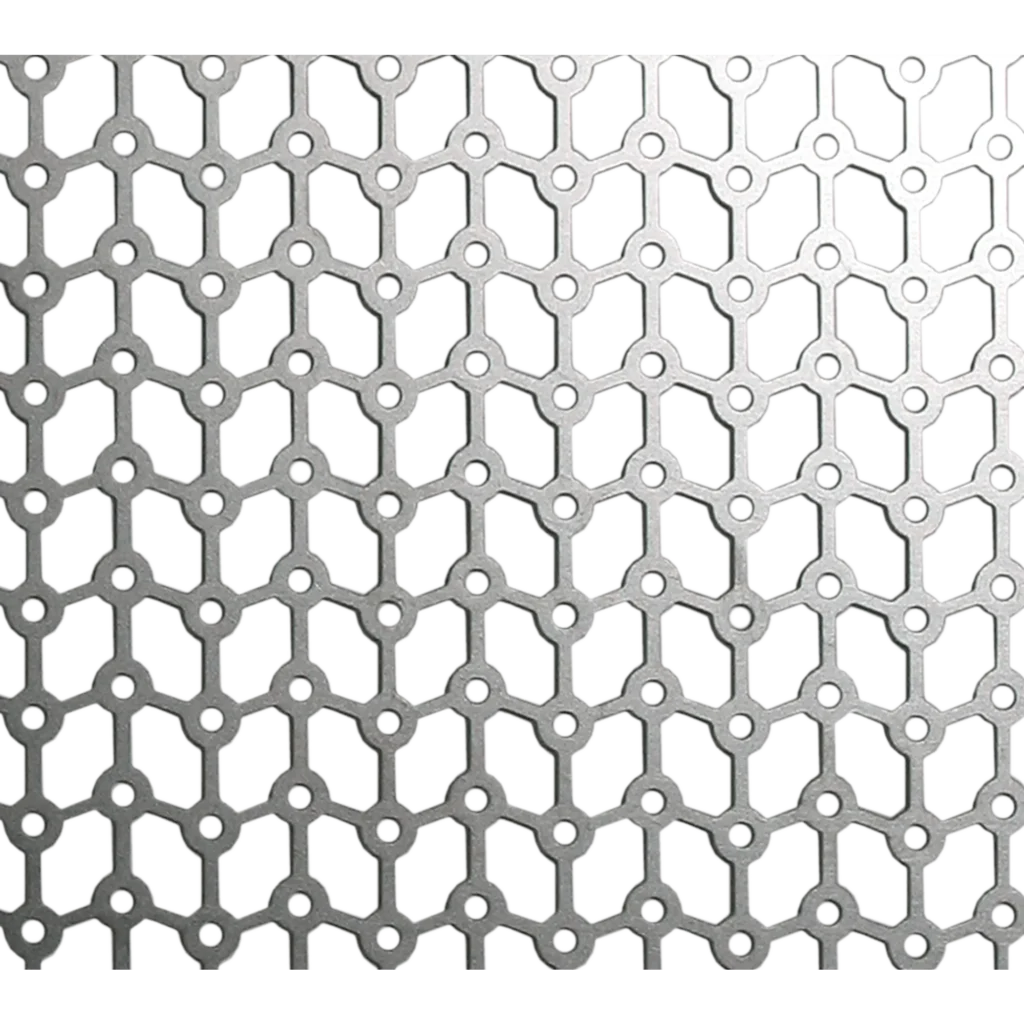

PEI’s expert engineers and operators craft surgical mesh meticulously using precision chemical machining (PCM) to support tissue regeneration and promote optimal patient outcomes. The PCM manufacturing process produces burr-free parts in intricate geometries, which are essential in precisely fabricating surgical meshes.

A surgical mesh is a medical implant that a surgeon uses to support weakened or damaged tissue or bones. Medical practitioners use surgical mesh in many procedures, including hernia repair, cranial, oral, orthopedic, and more.

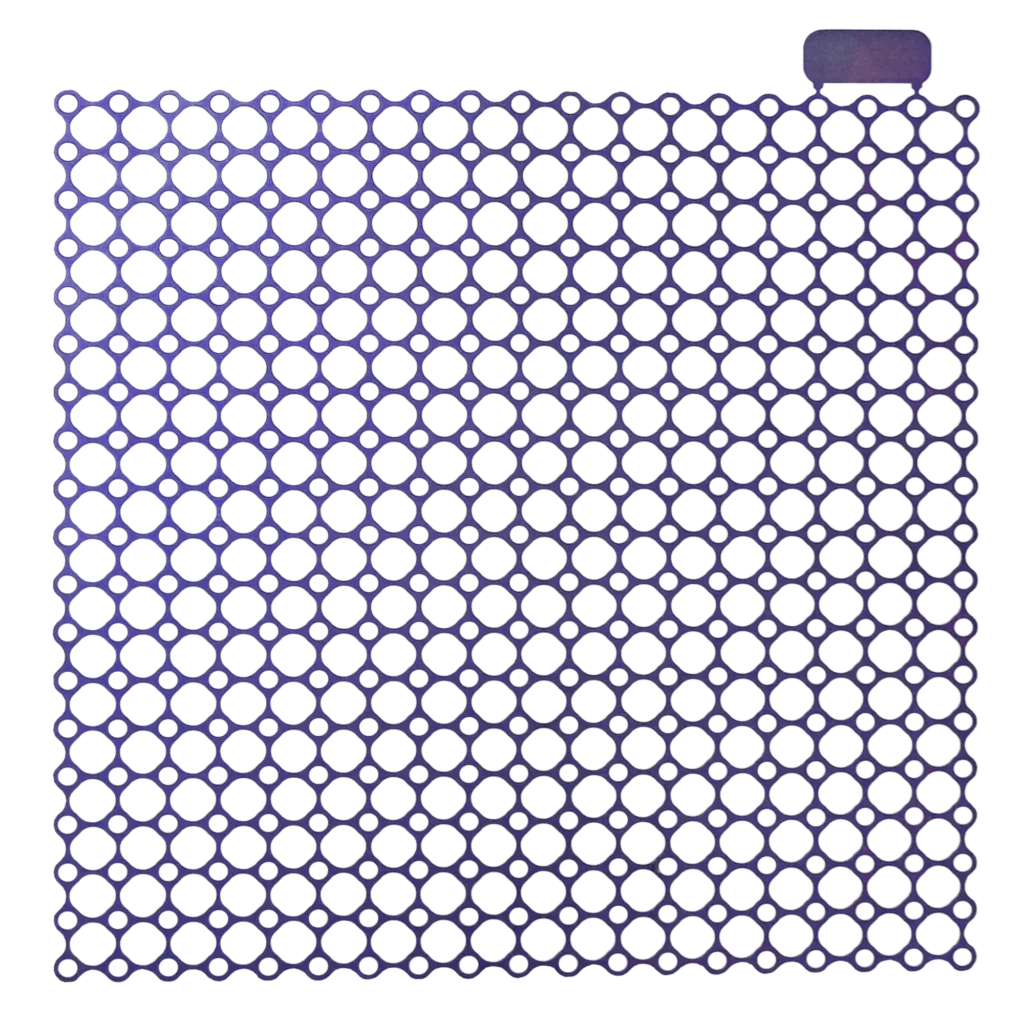

Manufacturers produce surgical meshes from synthetic materials and metals, like titanium. These materials must be strong, flexible, biocompatible, and can withstand corrosion.

PEI supplies titanium surgical mesh to leading medical providers. Titanium is exceptionally strong, lightweight, biocompatible, and resistant to corrosion. Our experts, who have decades of experience in the engineering and manufacturing surgical meshes, can help you understand the benefits of each material.

PEI fabricates titanium surgical mesh in custom shapes and sizes with integrated locations for mounting screws. Our meshes feature more open space in the mesh for improved weight-to-strength factors.

Key applications include:

By providing a strong, supportive structure, surgical mesh significantly reduces the risk of hernia recurrence. It reinforces the tissue to prevent the underlying contents from bulging through.

Surgical mesh provides essential support to facilitate healing, strengthen the tissue and restore its function, and prevent complications by reinforcing weakened or damaged tissue.

By supporting muscles and ligaments, surgical mesh helps restore organ position and reduce discomfort. This application has significantly improved the quality of life for countless patients affected by organ prolapse.

Photochemical etching, also known as precision chemical machining, chemical blanking, or acid etching, is an exact subtractive manufacturing process where chemical etchants selectively remove metal from a thin sheet to create intricate shapes, patterns, and features. Unlike traditional methods, photochemical machining does not involve mechanical force or direct contact with the sheet of metal, minimizing the risk of distortion, burrs, or stress-induced deformation.

The benefits of photochemically etching surgical mesh include fabricating precise parts with intricate geometries and accurate patterns.

Here are additional benefits of titanium photochemical etching:

With a history of engineering excellence, PEI is among the top companies providing photochemically-etched metal parts and components for a variety of critical industries.

With ISO-9001:2008 and AS9100 certifications, PEI was also granted certification under the International Traffic in Arms Regulation (ITAR) in 2010, enabling it to provide weapon system components and accessories in compliance with the Code of Federal Regulations implemented by the U.S. Department of State.

Our rigorous inspection processes and testing procedures ensure that every product we produce meets stringent accuracy, reliability, and performance standards.