With ISO-certified processes and deep expertise in biocompatible metals, PEI is helping medical innovators produce safer, stronger devices.

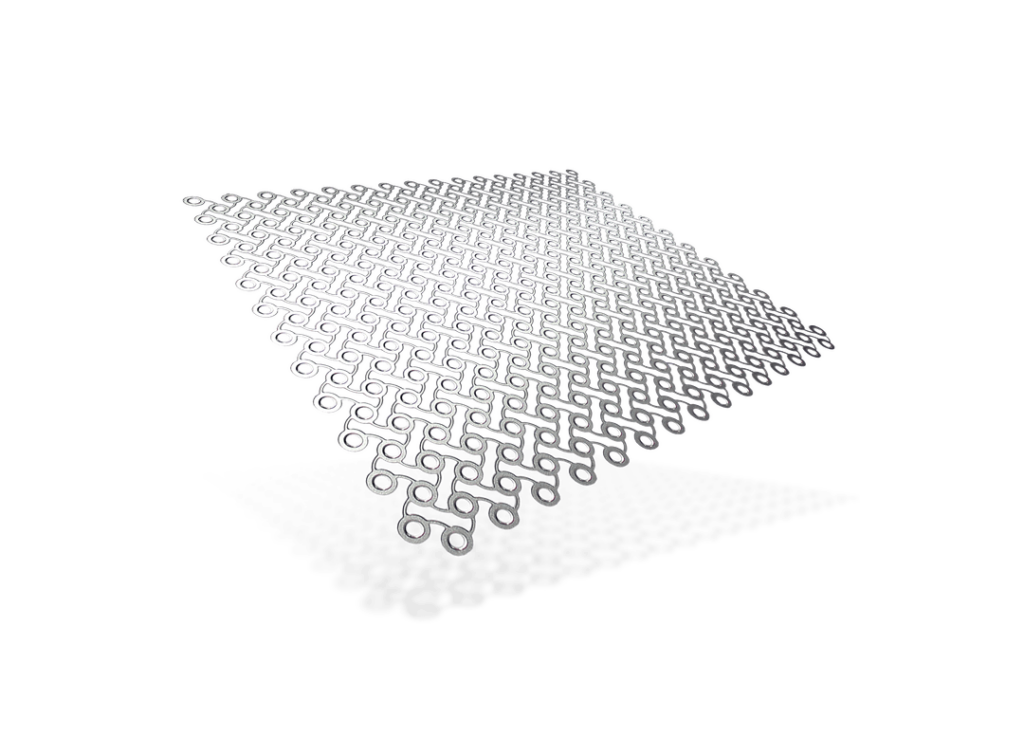

PEI produces custom-etched components for surgical and implantable devices using titanium and stainless steel 316, where precision and reliability can mean the difference between life and death.

Our advanced machining process safeguards the metal’s critical properties while delivering exacting tolerances, intricate geometries, and flawless edges, ensuring every part performs flawlessly in the most sensitive and demanding medical applications.

In the medical field, every component must perform with absolute consistency to support life-saving procedures and long-term patient health. That’s why healthcare professionals worldwide rely on PEI’s engineering, manufacturing, and quality assurance teams to deliver precision metal parts that meet the most rigorous standards. From surgical instruments to implantable devices, our solutions are trusted to function flawlessly when it matters most.

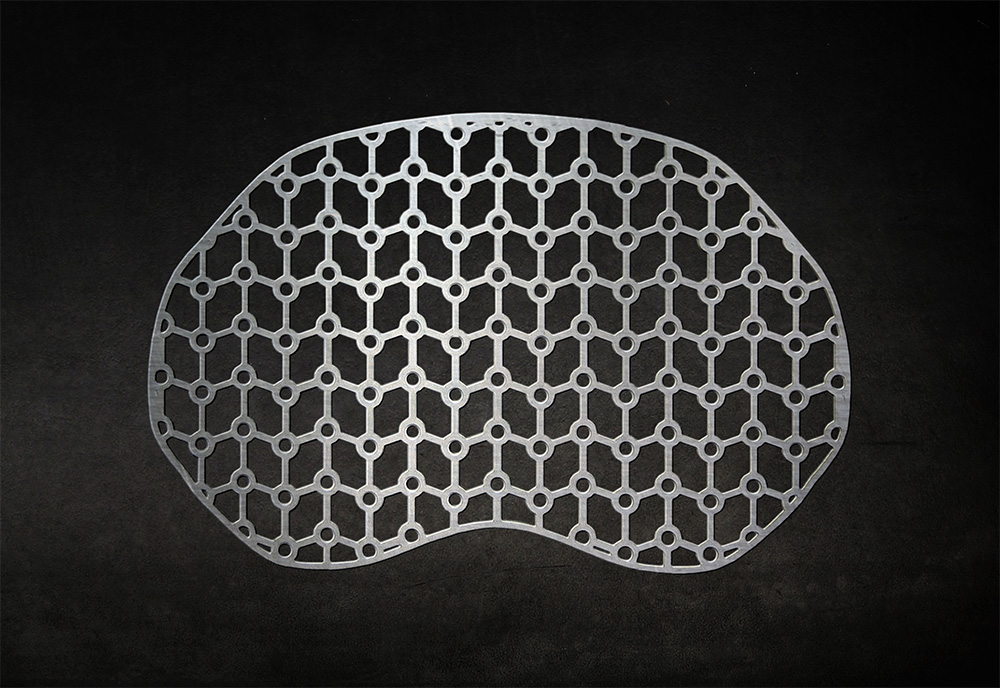

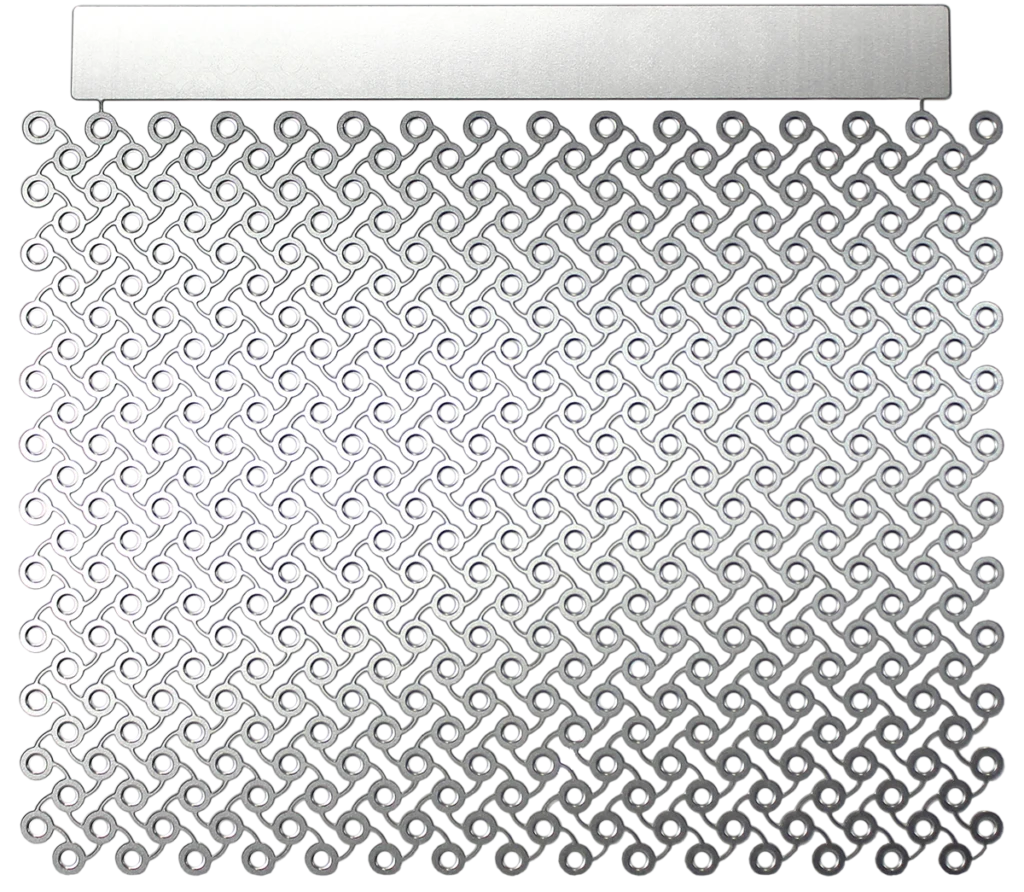

PEI is the world’s leading photochemical etcher of titanium, often called the wonder metal, producing cranial, surgical, and maxillofacial meshes, tools, implantables, and blades essential to modern medical procedures.

Our expertise lies in preparing titanium and selectively removing material through advanced surface modification techniques, ensuring each titanium surface is optimized for performance. The result is titanium components and etched parts that meet stringent medical guidelines while maintaining the biocompatibility and durability critical for patient safety.

Titanium has long been the industry standard for implantable medical devices thanks to its unique combination of biocompatibility, lightweight strength, and excellent corrosion resistance. It is safe for long-term implantation, integrates naturally with the bone, and maintains its structural integrity within the body for decades.

PEI specializes in etching titanium and titanium alloys for critical medical applications, including:

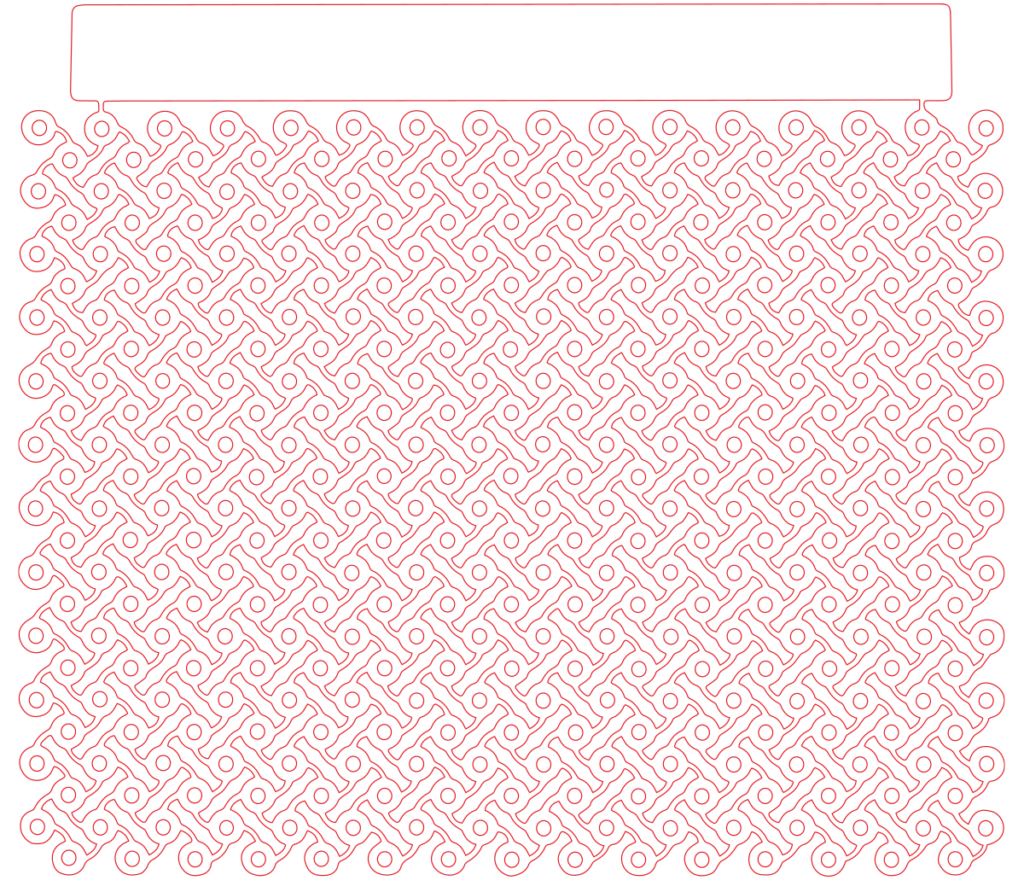

From pure titanium to advanced titanium components, our photochemical etching process delivers unmatched precision without compromising material integrity, which is critical for patient safety and long-term performance.

For certain surgical applications, stainless steel 316 offers a durable, corrosion-resistant, and cost-effective alternative to titanium. Its biocompatibility and mechanical strength make it ideal for:

Our photochemical etching process ensures consistent thickness, excellent surface finish, and repeatability, supporting both prototype development and high-volume production.

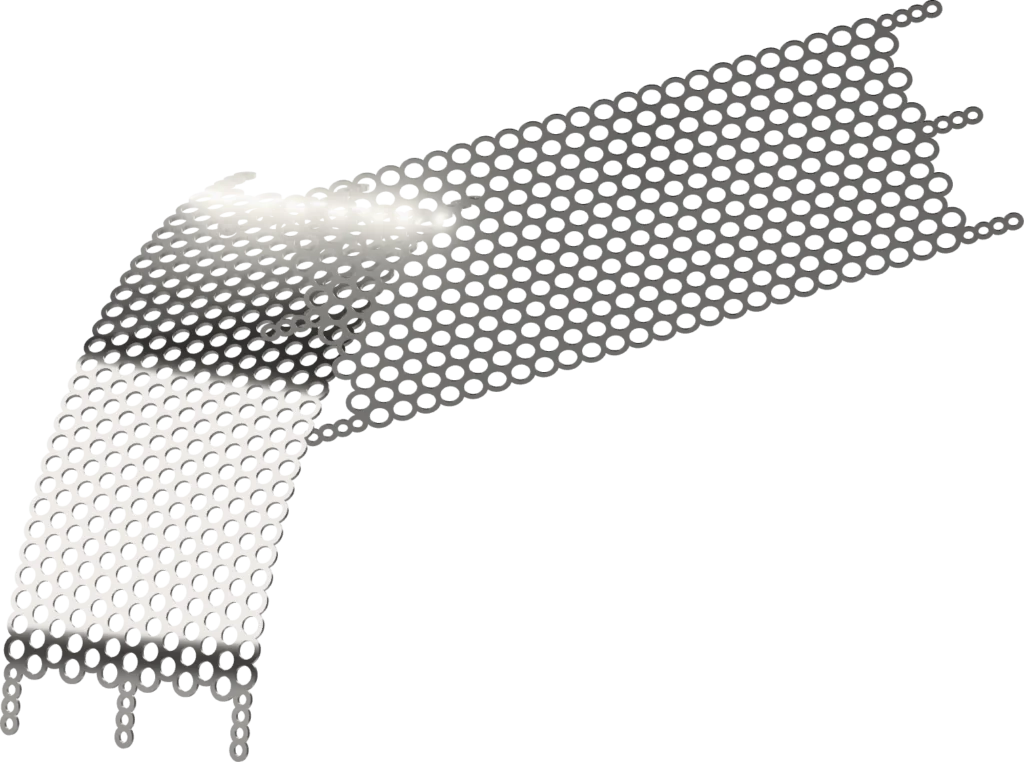

Our advanced etching process delivers precision results without introducing burrs, microcracks, or heat-affected zones—issues commonly associated with stamping, laser cutting, or machining. For delicate medical geometries, this means:

Our expertise ensures that every etched part meets the stringent quality requirements of the medical sector.

Our advanced machining and photochemical etching techniques are designed to preserve and enhance the natural corrosion resistance of titanium and stainless steel components. By using a carefully controlled etching solution that includes hydrofluoric acid, we precisely remove material without introducing stress, heat, or surface defects.

This meticulous approach ensures every medical component delivers superior corrosion resistance, even in the most demanding implant and surgical environments.

PEI leverages more than 50 years of photochemical etching (PCE) experience to deliver thousands of essential thin metal parts that save lives and improve health outcomes. PCE is an efficient and cost-effective manufacturing process that produces highly accurate parts with complex patterns and tight tolerances.

Our etchers work with a wide range of metals, including titanium, stainless steel, aluminum, tin-plated brass, copper, and more.

Our precision etching process enables the production of complex, burr-free medical components with unmatched accuracy and repeatability. By maintaining the base metal’s integrity and high corrosion resistance, our methods are ideal for manufacturing etched titanium parts and stainless 316 components that perform reliably in the demanding environments of the human body.

Our capabilities support a wide range of implantable and surgical-grade parts, including:

From rapid prototyping to full-scale production, we maintain stringent quality control and full material traceability, ensuring that every part meets or exceeds the standards of medical devices.

Industries and technologies evolve when people work together to push boundaries and uncover new solutions. For over 50 years, we’ve stood shoulder to shoulder as leading companies across every market sector push forward with revolutionary changes that change the world. We are ready to share and leverage knowledge and expertise to collaborate with our customers for mutual success.

PEI’s long history of meeting and exceeding industry standards and customer expectations began in 1968. For over 50 years, we’ve kept quality assurance at the forefront of our work by training our manufacturing teams, maintaining our equipment, and establishing rigorous internal controls. PEI holds several certifications, including ISO9001:2015, AS9100:2016, and ITAR. We adhere to MIL-STD-45662, MIL-STD-105, and ANSI/ASQC Z1.4 quality standards.

Partner with the world leader in etching titanium and stainless steel 316 for medical applications.