Titanium Parts Precision Chemically Machined

TITANIUM PARTS

PRECISION CHEMICALLY MACHINED

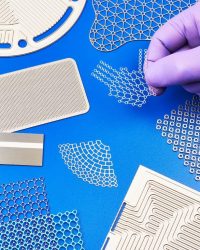

Custom chemically machined titanium parts for critical aerospace, battery, electronics, fuel cell, medical implantable, and related applications have been introduced by Photofabrication Engineering, Inc. (PEI) of Milford, MA.

PEI Precision Titanium Parts are chemically machined to exact OEM design requirements, including varying depths and intricate patterns, with exact part-to-part and batch-to-batch repeatability. Featuring burr-free and stress-free finishes, these precision photo etched titanium parts are not subjected to the potential deformation from stamping and provide greater design flexibility than laser cutting and water jet technologies.

Capable of chemically machining all sides of parts simultaneously, including channels and pockets, PEI Precision Titanium Parts can be produced in sizes from foil up to 28”W x 58”L and 0.005” to 0.090” thick with tolerance ±10% of material thickness. The photo etch process requires no hard tooling that can wear, permits rapid prototyping, and is equally well suited for nickel and stainless-steel parts. PEI is ISO 9001, AS 9100, and ITAR registered.

PEI Precision Titanium Parts are priced according to configuration and quantity. Price quotations are typically provided within 24 hours.

For more information contact:

Photofabrication Engineering, Inc.

Robert D. Ashman, National Sales Manager

500 Fortune Blvd.

Milford, MA 01757

(508) 478-2025 FAX (508) 478-3582

e-mail: rashman@photofabrication.com

www.photofabrication.com