As the world transitions toward renewable energy solutions, hydrogen fuel cells have emerged as a key technology offering a clean, efficient, and sustainable alternative to fossil fuels. With their ability to produce electricity with zero carbon emissions, these powerful cells are driving innovation across industries, from transportation to stationary power generation, and leading the global push toward decarbonization.

With new technologies and processes continually being developed, the fuel cell manufacturing process has become increasingly complex, making it more important than ever to partner with a trusted manufacturer with a history of producing accurate, durable, and dependable metal parts.

As demand continues to grow, PEI has positioned itself as a leader in precision component manufacturing for hydrogen fuel cell technology. With decades of expertise in precision chemical machining and advanced metal fabrication, we’ve developed a reputation for producing high-performance components critical for efficient energy conversion in fuel cells. Committed to sustainability and innovation, our innovative solutions empower industries to transition toward clean energy while maintaining exceptional quality and reliability.

This article explores the critical components of fuel cells, the importance of precision in fuel cell manufacturing, and the role of quality control and customization in reliable, efficient fuel cell production.

What is a Hydrogen Fuel Cell?

A hydrogen fuel cell is an electrochemical device that converts chemical energy into electricity and is critical in efforts to produce hydrogen as a clean energy source.

The parts of a fuel cell are:

- The fuel cell stack.

- Fuel cell electrodes.

- Fuel cell membranes.

- Fuel cell separators.

- Fuel cell control systems.

One of the most widely used types is the Proton Exchange Membrane (PEM) fuel cell, which generates electricity by facilitating a reaction between hydrogen and oxygen. The only byproduct? Water (H₂O), making it a truly zero-emission technology.

Fuel cells are highly versatile, powering applications such as:

- Fuel cell electric vehicles (FCEVs): These hydrogen fuel cell vehicles include buses, trucks, and passenger cars. For example, in 2025, New Flyer’s hydrogen fuel cell buses will be deployed across the U.S., including in California, Washington, Arizona, Nevada, and New York.

- Stationary power systems for buildings and industrial facilities.

- Hydrogen energy storage solutions that support renewable energy integration and grid stability.

The key advantage of using hydrogen lies in its abundance. Whether derived from natural gas or renewable resources, producing hydrogen for fuel cells provides an inexhaustible, green energy source capable of meeting the world’s energy needs without harming the environment.

PEI’s Specialized Capabilities in Hydrogen Fuel Cell Component Manufacturing

PEI’s advanced manufacturing capabilities address the unique challenges of hydrogen fuel cell technology, delivering precision components that meet the exacting standards of this highly regulated industry.

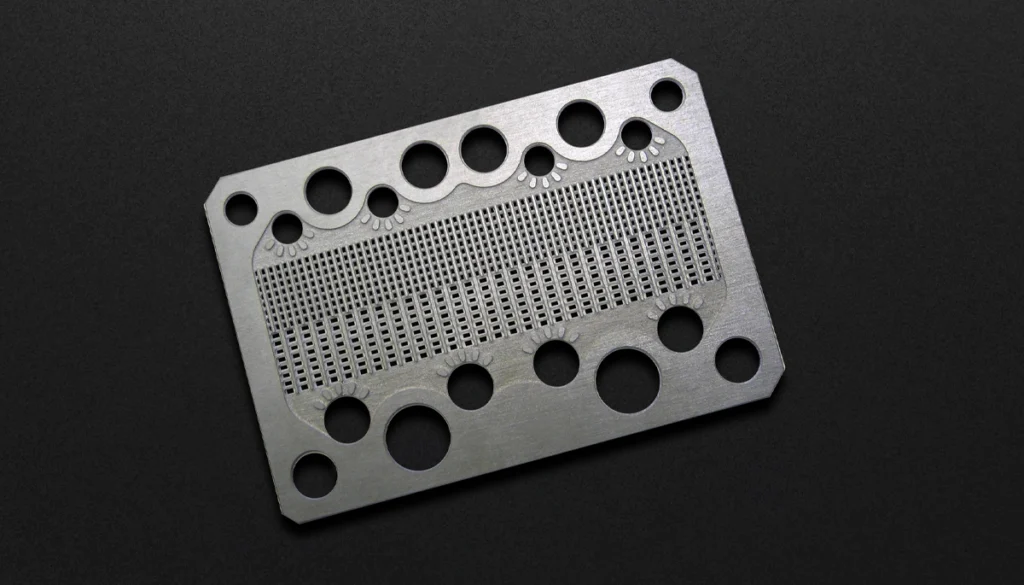

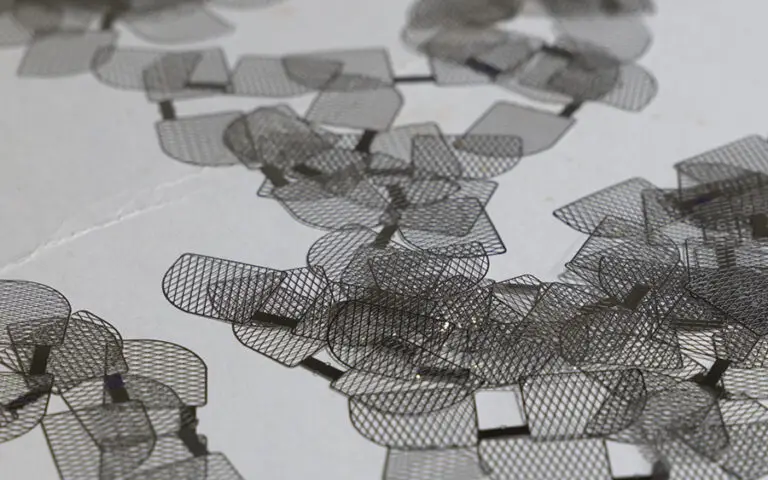

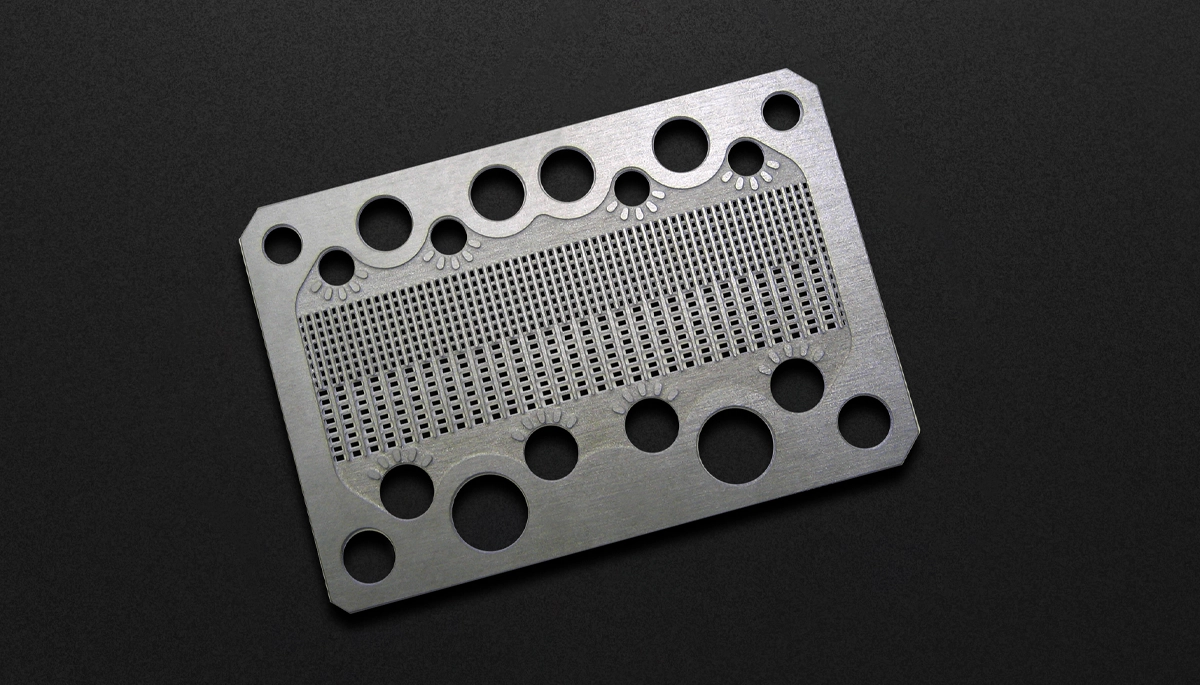

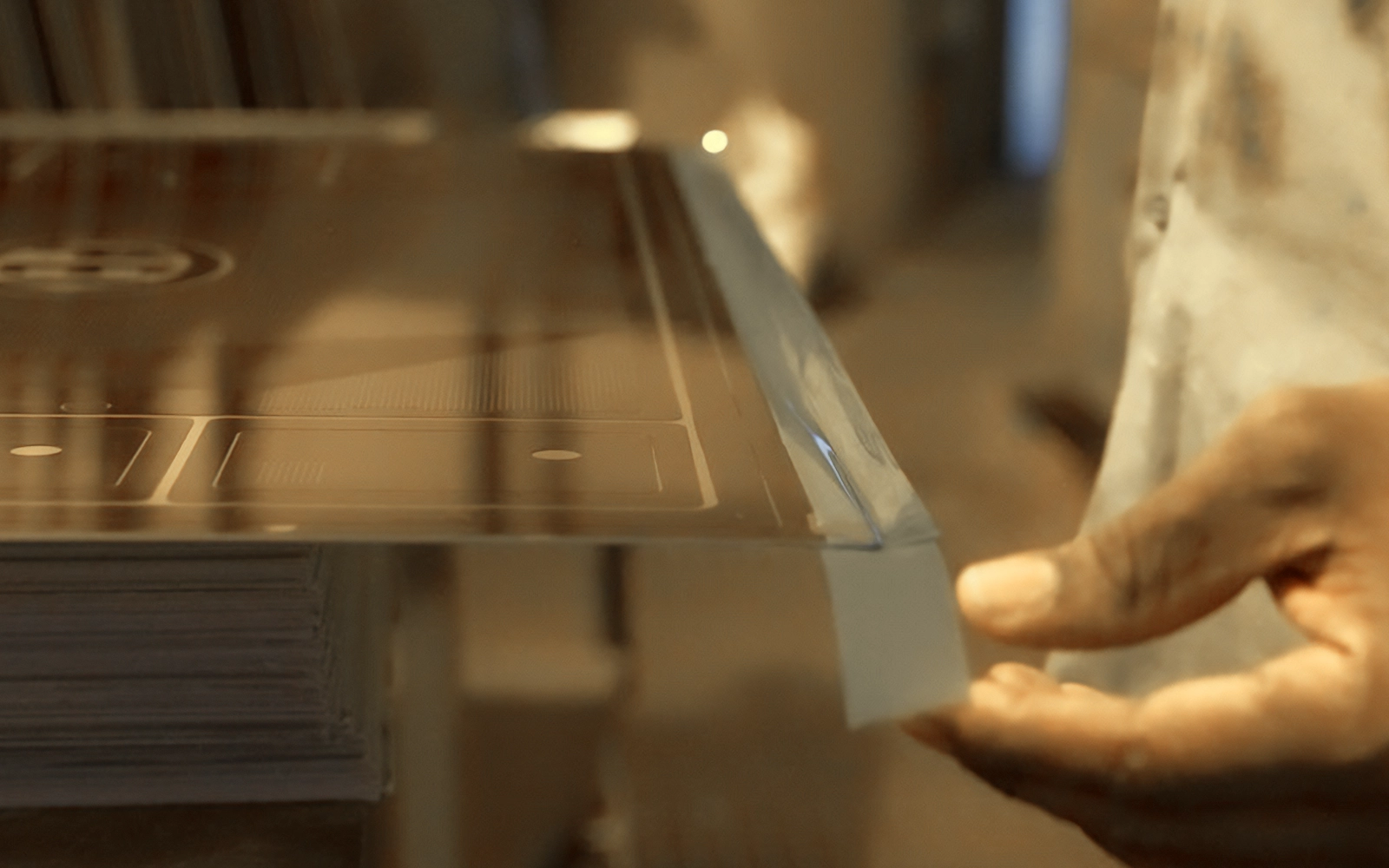

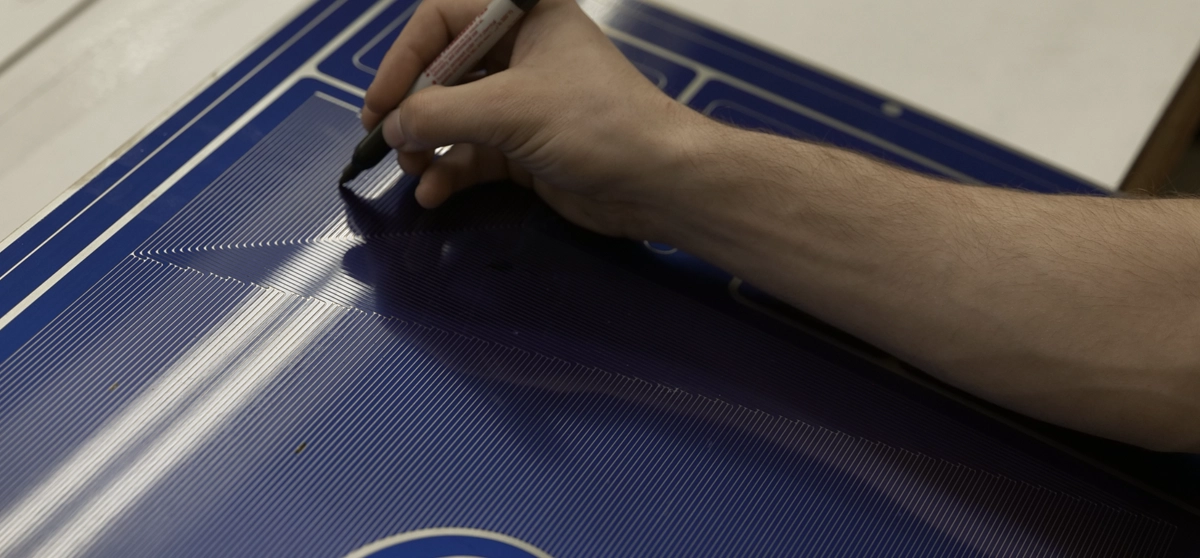

Using our proven photochemical etching process, we create a range of critical components for Hydrogen Fuel Cells with complex patterns and tight tolerances.

Some of the high-precision components we specialize in include:

- Flow Plates: Channels that guide the flow of hydrogen and oxygen within the cell.

- Separators: Essential for maintaining the integrity and performance of the fuel cell stack.

- Current Collectors: Components that efficiently transmit electricity generated within the cell.

Unparalleled Precision and Reliability

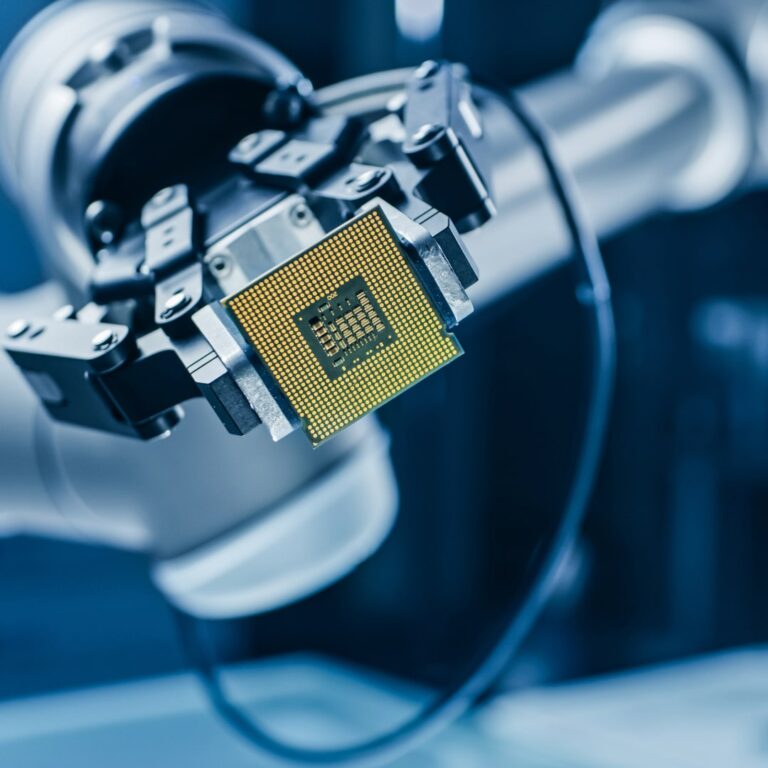

When it comes to hydrogen production, precision is everything, which is why PEI’s team of skilled engineers and technicians ensures every component meets the highest standards for accuracy, reliability, and durability. These parts are critical in applications like solid oxide fuel cells, supporting renewable electricity generation and sustainable hydrogen production.

By achieving complex designs and thin-walled components with exceptional accuracy, the team at PEI enables the production of high-performance fuel cell systems capable of meeting today’s growing energy demands.

PEI’s Innovative Manufacturing Processes

At the heart of PEI’s success lies a commitment to leveraging cutting-edge manufacturing techniques tailored to the unique requirements of hydrogen fuel cell technology.

With decades of experience and a daily dedication to perfection, we can deliver precise, durable, and reliable quality parts you won’t find anywhere else.

The secret lies in our advanced precision chemical machining process. This innovative process enables us to create intricate designs and precise geometries without introducing mechanical stress or material distortion. Unlike traditional methods like stamping or laser cutting, chemical machining ensures:

- Material Integrity: No heat or mechanical stress is applied, preserving the material’s properties.

- Superior Precision: Achieves tight tolerances and complex geometries for high-performance components.

Our meticulous engineers and operators, as well as our dedicated quality assurance professionals, ensure that each component is manufactured to the exact specifications. From flow plates to separators, these processes deliver the precision and consistency required for efficient and reliable hydrogen production systems.

When you partner with the PEI, your fuel cell components come with the advantages of:

- Improved Durability: Enhanced resistance to wear and tear.

- Increased Efficiency: Components designed for optimal energy conversion.

- Fast Adaptation: Digital tooling minimizes lead times, allowing for quick design modifications.

Quality Control and Customization

As a trusted partner to hydrogen fuel cell manufacturers, our commitment to quality assurance and customization is what sets it apart.

Rigorous Quality Assurance

Our Quality Assurance team leverages decades of experience and the latest inspection tools to ensure everything from our advanced manufacturing facility meets stringent regulatory and safety standards.

We take a multi-phase approach to quality assurance that starts with our engineers, continues on the production floor, and finishes at our Quality Assurance department. Every component undergoes thorough real-time inspections and testing, and only the highest quality components leave the floor.

We’re ISO9001:2015 and AS9100:2016 certified and ITAR compliant, ensuring that every component meets or exceeds client expectations.

Endless Customization Options

We understand that technology is continually advancing, so we offer extensive customization options to meet the specific requirements of each project. From prototype development to high-volume production, PEI tailors its solutions to deliver:

- Stack Configurations: Customized layouts for optimal fuel cell performance.

- Material Specifications: Precision components made from materials suited to hydrogen applications.

- Scalable Production: Capacity to meet the growing demands of renewable energy projects.

By providing bespoke components, we ensure seamless system integration and enhance the flexibility of hydrogen production systems.

Building a Future of Clean Energy

As the transition to clean energy solutions continues to gather pace, hydrogen fuel cell technology is playing a key role in shaping a sustainable future. With these powerful cells finding more and more applications across industries, the demand for precision fuel cell components is growing and growing fast.

As the world leader in precision chemical machining, PEI has become a trusted manufacturing partner for specialized components for hydrogen fuel cells. With our ability to deliver intricate, stress-free designs, combined with our commitment to quality and innovation, we consistently deliver reliable, high-performance components that meet the complex demands of renewable energy systems.

Boasting decades of industry experience, advanced manufacturing processes, and stringent quality control systems, we take on the challenge of saving the world’s environment every day.

Together, let’s build the future of clean energy.

Contact us to discuss our innovative solutions or request a quote.

Fueling the Transition to a Sustainable Future

With its potential to replace fossil fuels in various sectors, particularly in industries and applications that are challenging to electrify directly, hydrogen is fuelling the world’s transition to a more sustainable future.

Directly impacting the success and longevity of hydrogen production projects, the selection of a PEM electrolyzer manufacturer has quickly become an incredibly important decision. By evaluating manufacturers on factors like technological innovation, material quality, customization capabilities, regulatory compliance, and cost-effectiveness, you can ensure you’re investing in systems that deliver high performance and efficiency over the long term.

When the mission is to save the world’s environment, precision is the only option. PEI brings decades of experience and industry-leading expertise to take on the challenge every day. With our proven expertise in precision machining and commitment to quality, you get access to reliable, high-performance components that support the complex demands of hydrogen production.

Our precision parts are crucial in applications such as solid oxide fuel cells and solid oxide electrolyzers, supporting advanced solutions in renewable electricity and sustainable hydrogen production.

If you’re looking for expert advice or specialized precision components for hydrogen-related applications, PEI is the trusted partner for achieving optimized performance in PEM electrolyzers. Reach out to our team today to learn more about how we can support your project needs and drive success in your hydrogen production initiatives.