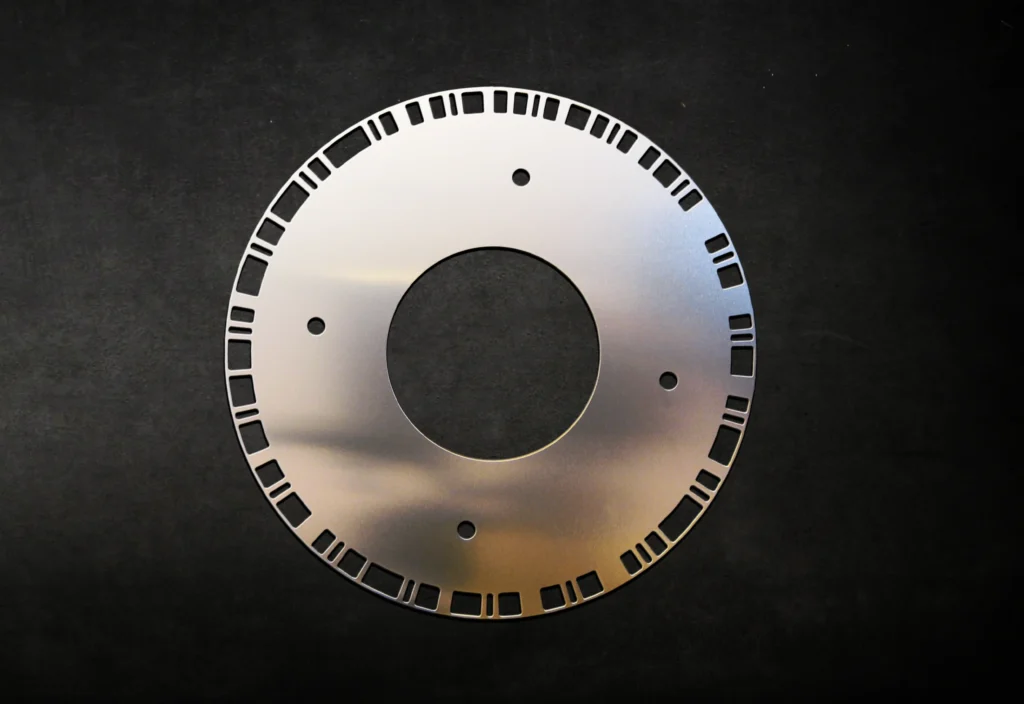

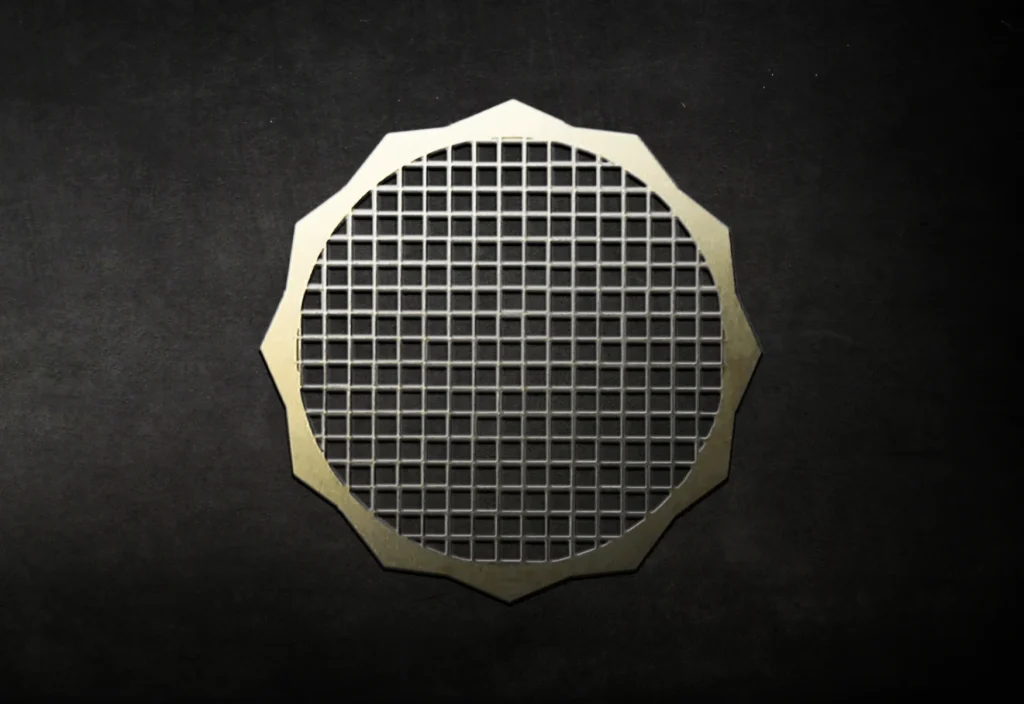

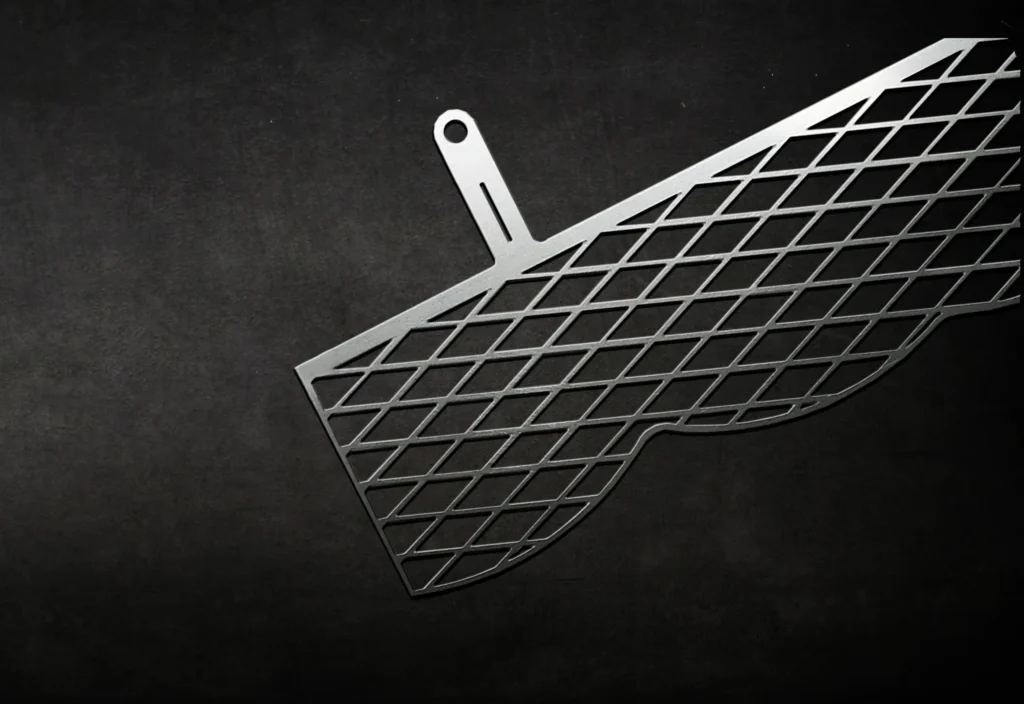

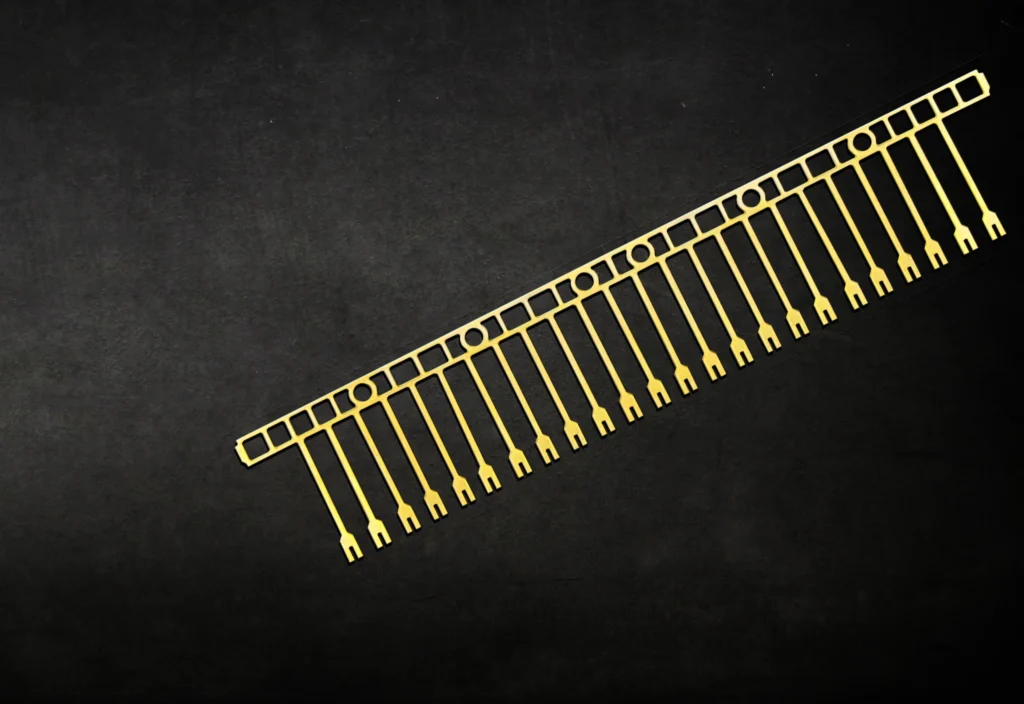

The photochemical machining (PCM) process consists of several important steps. Each step is a critical prerequisite to the next. Although companies that produce parts using the PCM process have unique and sometimes proprietary methods to achieve the final goal, the basic operations are similar.

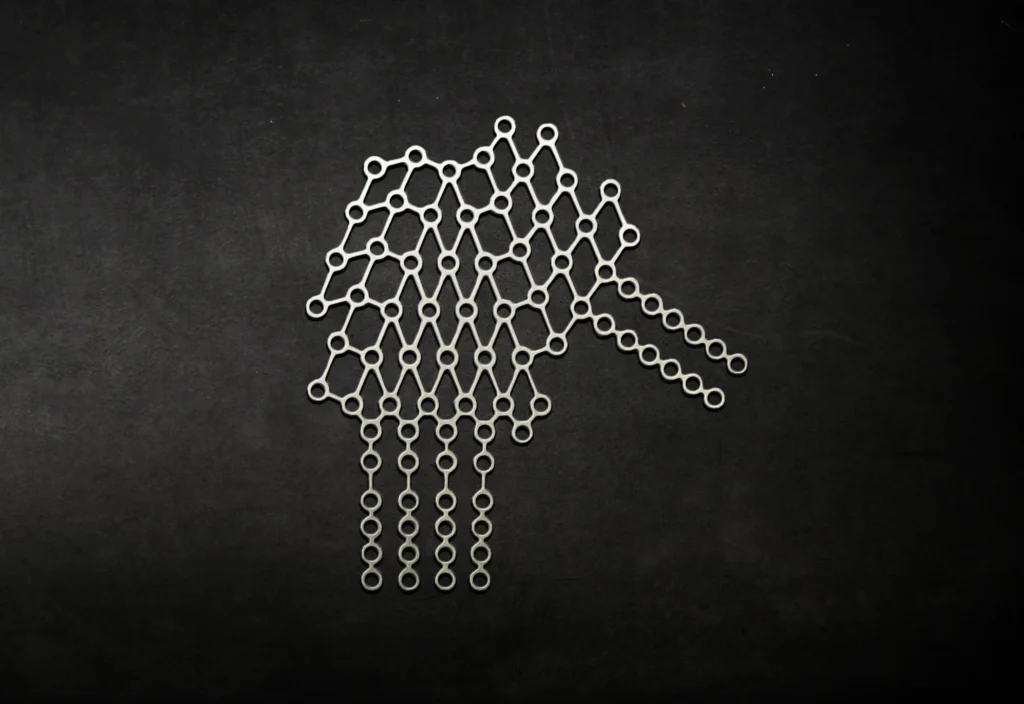

PEI leverages the latest technology and tried and true processes to produce precise, thin metal parts, depending on the size, volume, complexity, and level of definition required for each new part. PEI’s engineering team works with CAD drawings supplied by our customers, modifying the dimensions to compensate for the unique characteristics of the PCM etching process. An engineer must consider a part’s features, compensating for surface and lateral etching, which happen simultaneously during the etching process.

Depending on the part, each CAD drawing goes from our engineering team to either a Mylar tool printing machine or an LED printer that directly exports the part’s image on the metal plate. An engineer arrays that image over an area specified by the tooling engineer to maximize the number of units per metal sheet. Then, the image is sent to a laser photo-plotter, created on a piece of Mylar film, and developed. If all features on both sides of the part are identical, we create a duplicate film. The manufacturing team punches holes in the two pieces of film, aligning each top to bottom. We punch registration holes in both pieces of film, which is critical to prevent misalignment of the film during subsequent processing.

Once the material has been cut to the specified sheet size, it’s either mechanically or chemically cleaned to remove all foreign debris, dust, grease, oil, and other contaminants from the surface so that the photoresist can adhere to the metal. Many years ago, the common cleaning method for metal sheets in the PCM industry was solvent degreasing with solvents such as trichloroethylene. The environmental hazards of using these solvents became quite apparent, and in the late 1980s, PEI became the first PCM manufacturer to have a solvent-free facility. Coming up with alternative degreasing procedures was a huge undertaking, but it put PEI on the path to becoming the first company in the photo chemical machining industry to “go green.”

Today, most metals are cleaned using mild soaps or alternative cleaning methods. Often, but not always, sheets of metal are fed through a large four-chamber/stage conveyor spray machine, with each chamber containing a different concentration of cleaning agents, as well as three stages of rinsing after the cleaning. Using high pressure, and rinsing the sheets with two chambers of city water before a final rinse of deionized (DI) water, insures that the sheets are truly clean and ready for the next step in the PCM process. Some materials require a different chemical preparation.

The next step in the process is the application of photoresist. Because PEI uses an aqueous dry-film photoresist, we refer to it as “the coating operation.” The coating operation is exactly what it sounds like – dry-film photoresist is rolled onto the cleaned metal sheets using a hot-roll lamination system. At this point in the process, the sheets of metal are processed in a safe-light environment.

PEI only uses dry film photoresists (rather than liquid types) because dry film makes more sense for volume applications, tends to be more controllable, and in most cases, can be easily removed. Dry film can also be used to mask for selective plating or other types of finishing operations.

While PEI typically coats both sides of a metal sheet previously cut to size, in some cases, metals in thinner gauges can bypass the prep process, and the resist can be applied to the entire coil. This is because thinner gauge material is generally clean of contamination and will not be exposed to harsh chemistry long enough for the photoresist to fail. Once the sheet or coil is coated with photoresist all edges are trimmed of the excess. At this point, the material is ready for exposure.

We also perform some manner of prep work on many of our materials that are coated by coil.

PEI leverages the precision of two ALTIX LED printers for printing, enabling us to push innovation to a new level. The LED direct imaging capability offers exceptional tool alignment accuracy and repeatability. The LED light within the printers exposes only the sections of the photoresist as specified by the digital artwork. Areas on the photoresist that are not exposed to light will not harden or cure, so an image is formed in the photoresist.

PEI also utilizes several contact-style printers depending on the part’s design requirements. Two pieces of film (the phototool) sandwich the metal sheet within the contact printing equipment. The operator creates a vacuum to prevent air bubbles and ensure no gaps between the phototool and the metal exist before UV light hits the panel. The design of a phototool allows only the appropriate areas of the design to be exposed to UV light, creating an image in the photoresist.

PEI’s coat and print equipment now resides in an updated state-of-the-art clean room to ensure the cleanest environment possible and to prevent FOD acquisition.

Once the image has been printed onto the metal sheet, it is ready for development in the wet process area.

All sheets that have been coated and exposed must go through a conveyorized developing system. The unexposed areas of the photoresist are rinsed off in a high-pressure alkaline solution, exposing the bare metal and leaving resist on those areas that have to be protected from the etchant. The developing process forms an adherent, durable image on both sides of the metal, which is now ready for the etching process.

PEI invested in a new double-wide developing machine in 2024, enabling our manufacturing teams to produce twice the yield on each run.

PEI uses several types of etchants, depending on the base metal being etched. Each etchant has attributes that are measured to ensure they remain robust and at proper concentrations. These include titration, monitoring of free acid levels, and testing the ORP (oxidation-reduction potential) of a specific etchant, among others. Some etchants are regenerated in the process, while others are refreshed through the addition of new chemistry to the etching equipment.

The metal sheets are placed in a large conveyorized spray system that sprays them from both sides with the appropriate etchant chemistry, dissolving the bare metal. The speed of the conveyor is carefully calibrated so that when the sheets approach the final rinse chamber, they are completely etched through, and all dimensions are held within specified tolerances.

We have the ability to etch in sheets or as individual parts.

After etching and rinsing, the sheets are ready to remove the photoresist.

PEI continues to invest in its etching capacity and chemical management technologies, spending more than $3M on new etching equipment to drive increased capacity and systems to optimize chemical supply to each machine.

The etched metal sheets still have the photoresist on the un-etched portions. Depending on the specific resist applied, they are either tank-stripped or stripped on PEI’s 30-foot conveyorized spray stripper using a solution, often a sodium hydroxide-based solution. Once stripped, the sheets are cleaned in city water, then rinsed in deionized water and dried.

After the photoresist has been removed, the parts or sheets go on to be inspected and packed for shipment to the customer or prepared for secondary operations such as plating, forming, lapping, welding, soldering, etc.

PEI prides itself on providing the highest level of Quality for all products we produce. Every new part that is etched requires a First Article Inspection (FAI) before Production is released. Every dimension is verified and once FAI approval has been achieved, the process variables utilized are locked for repeatability going forward.

We inspect to industry standards (Military/Aero, Medical or other) but will gladly establish a custom inspection plan designed specifically to satisfy all our customer expectations.

PEI ensures no detail is overlooked, especially how your parts will get from us to you. Packaging is critical to guarantee the products ordered aren’t damaged in transit. We support this important objective through the creation of custom packaging containers such as…

Be sure to let us know of any specific areas of concerns and we’ll address accordingly!