The PEI engineering team leverages years of manufacturing experience and technical knowledge to ensure that every part and component meets or exceeds customers’ stringent specifications. Our mechanical engineers examine a part’s design, objectives, and specifications while working with our customers to find the most efficient and cost-effective manufacturing method. Our intention is to optimize the process for the best results — becoming a true partner.

Our team features decades of mechanical engineering, materials, chemical, and process expertise that benefits our customers daily. We are well-versed in the latest technologies, manufacturing options, and materials and have experience working in renewable energy, aerospace, defense, medical, and technology sectors.

PEI’s engineers spend as much time on our production floor and with our quality assurance teams as they do looking over drawings and technical specifications. Their 360-degree approach to every project benefits our customers every step of the way.

The engineers who design a part, no matter its purpose, need to collaborate with engineers from the manufacturing facility to ensure it performs as needed. This collaboration offers feedback on design, performance, material and manufacturing options, and technical specifications.

When engineers work together, the benefits are clear throughout the process — better performance, more efficient manufacturing runs, cost savings. Plus, when smart people work together, it’s possible to uncover a new solution to an old challenge.

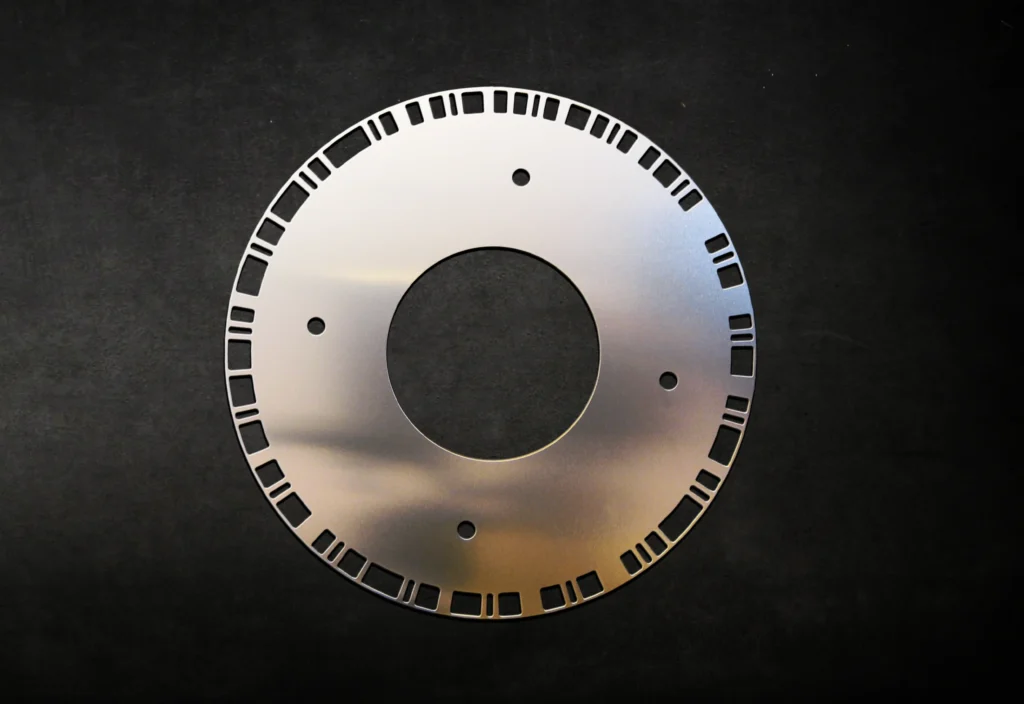

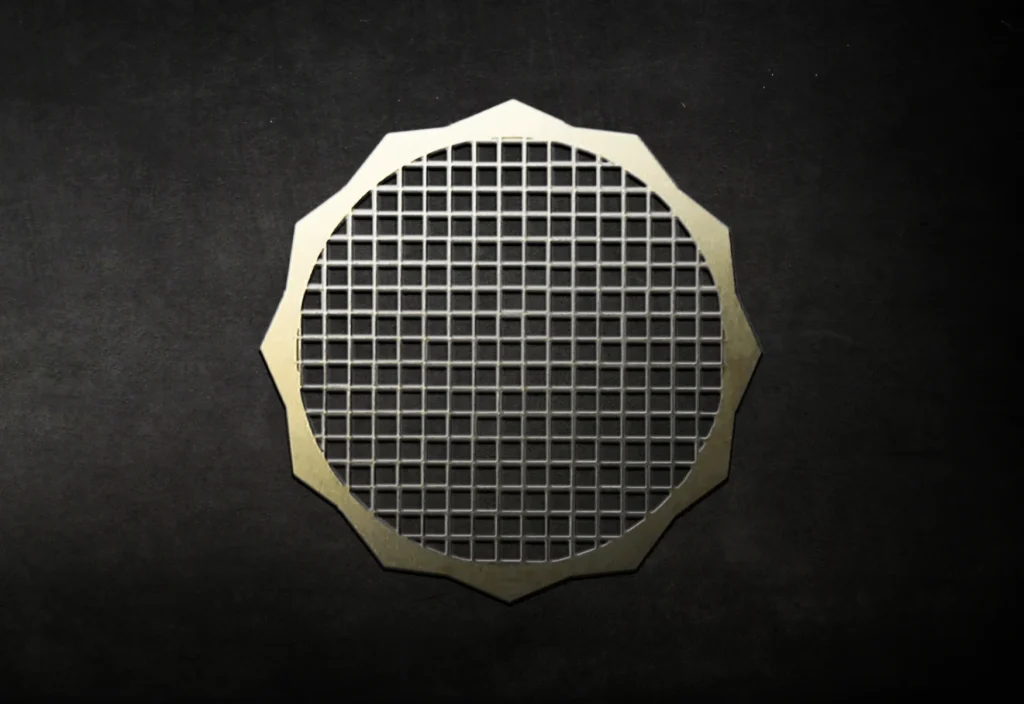

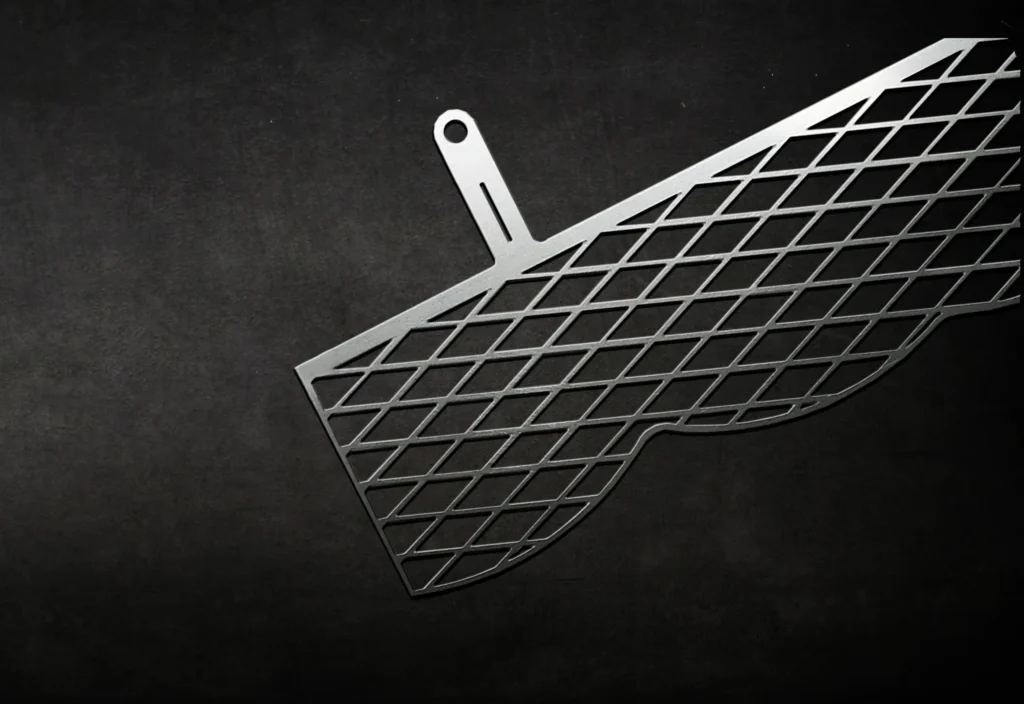

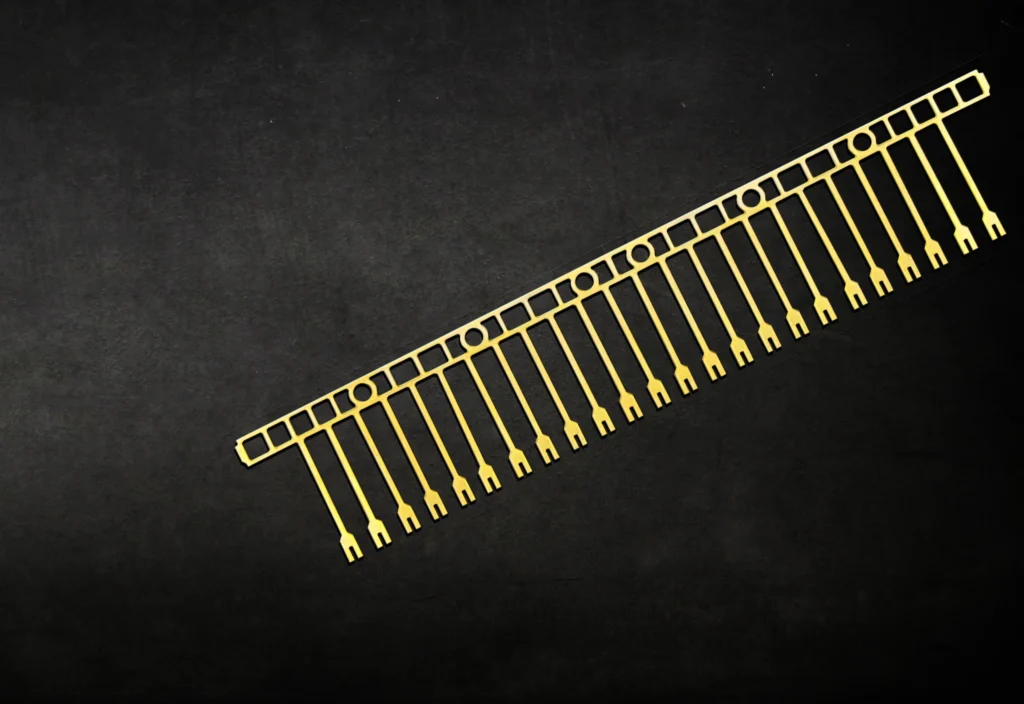

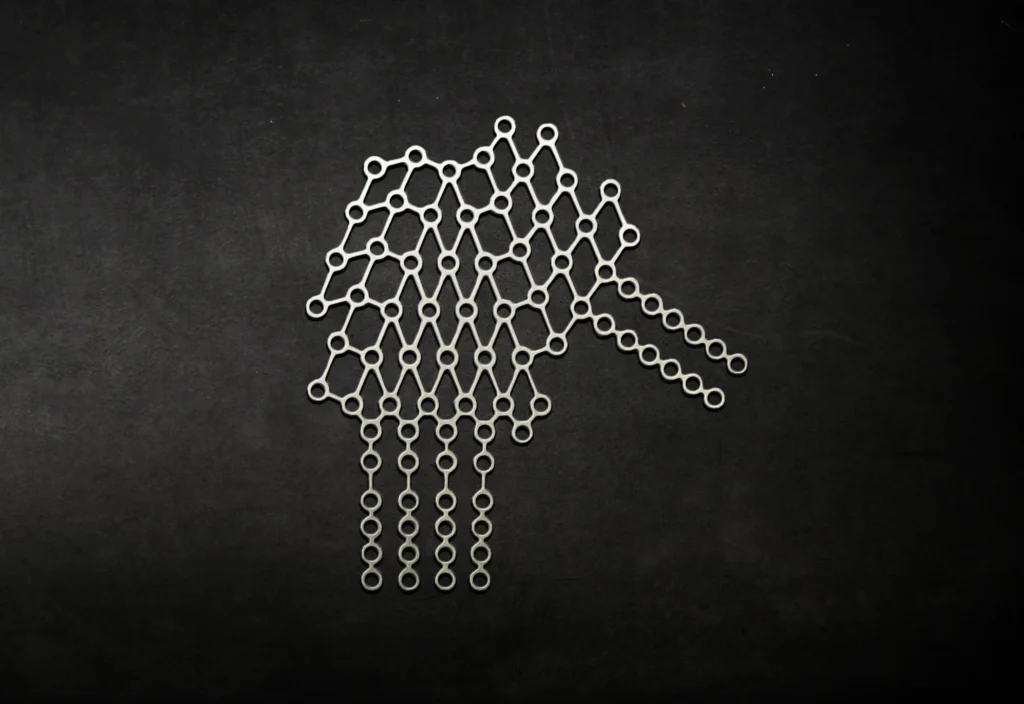

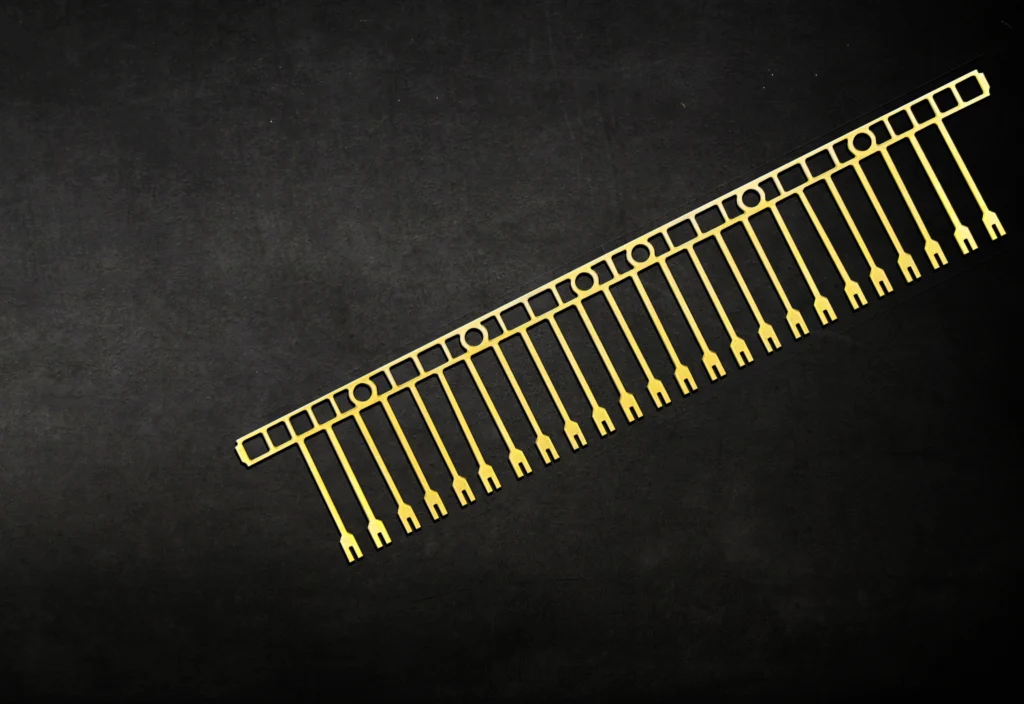

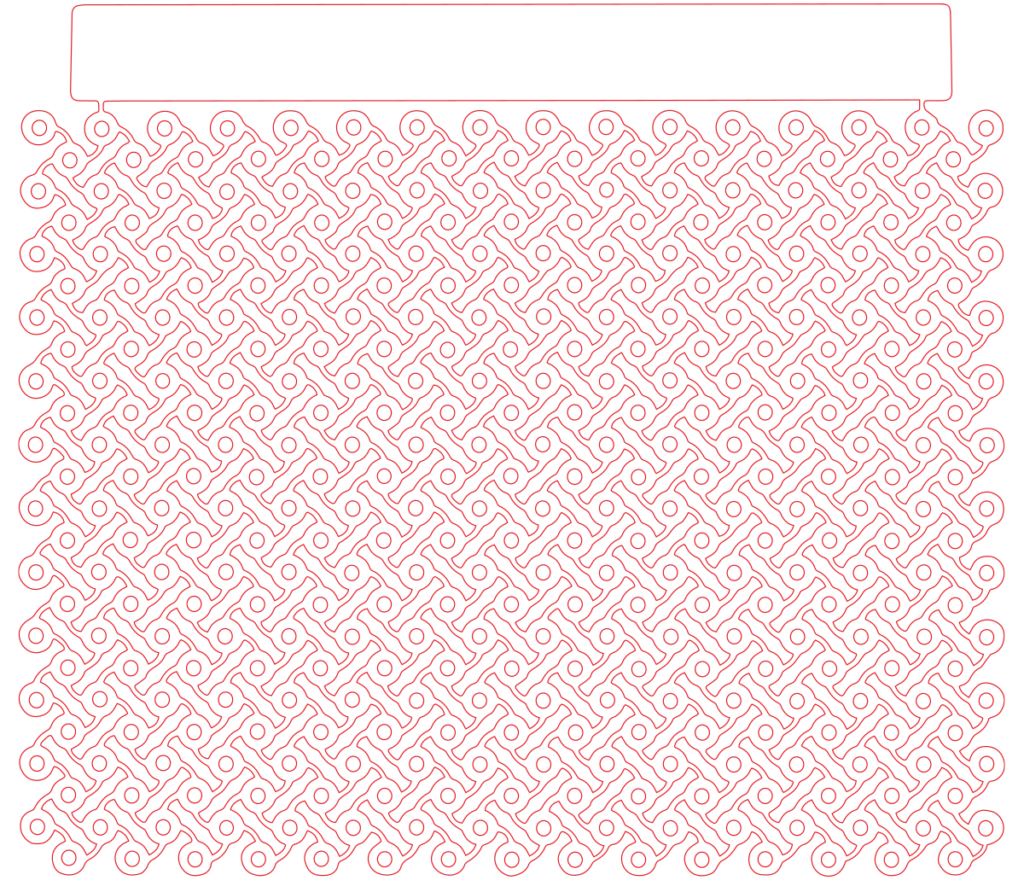

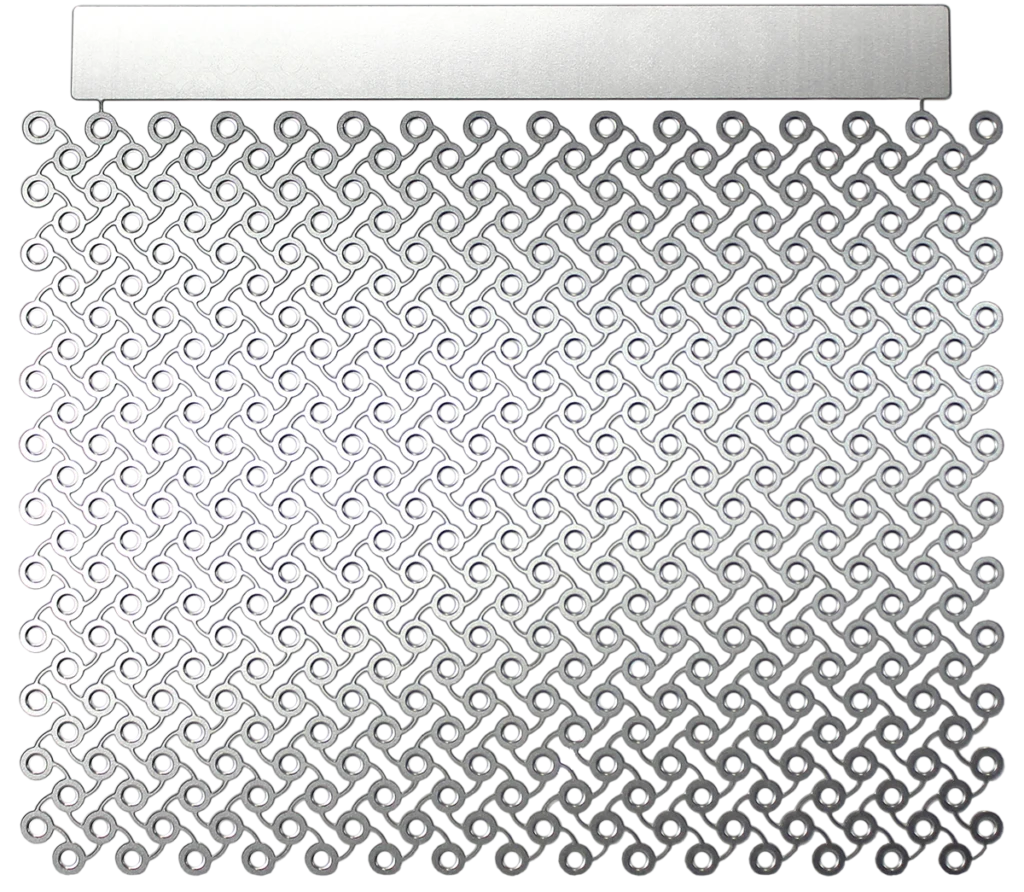

PEI’s commitment to delivering thin metal parts and components utilizing precision photochemical etching dates back decades. We are the world’s leading etcher of titanium and can handle aluminum, beryllium copper, molybdenum, and many other metals. PCE is an ideal manufacturing process for rapid prototyping and high-production runs.

Our precision operators turn thin metal parts into reliable components with meticulous machine and manual forming techniques to meet our customers exact design specifications.

Protecting precision metal parts from corrosion, wear, and environmental hazards is job number one when applying coatings, finishes, plating, or paint. PEI’s finishing capabilities will meet or exceed industry standards and requirements.

PEI delivers durable and reliable assembled components found in power-generating, life-saving, and high-technology applications worldwide. Our expert team of engineers and operators team to ensure our partners receive ready-to-implement solutions that will last.

The PEI Quality Assurance team analyzes every thin metal part and component to ensure its precision, accuracy, and durability. Our team uses a combination of technological and manual inspection techniques to ensure part perfection before any part or component leaves our facility.

Industries and technologies evolve when people work together to push boundaries and uncover new solutions. For over 50 years, we’ve stood shoulder to shoulder as leading companies across every market sector push forward with revolutionary innovations that change the world. We are ready to share and leverage knowledge and expertise to collaborate with our customers for mutual success.

PEI’s long history of meeting and exceeding industry standards and customer expectations began in 1968. For over 50 years, we’ve kept quality assurance at the forefront of our work by training our manufacturing teams, maintaining our equipment, and establishing rigorous internal controls. PEI holds several certifications, including ISO9001:2015, AS9100:2016, and ITAR. We adhere to MIL-STD-45662, MIL-STD-105, and ANSI/ASQC Z1.4 quality standards.