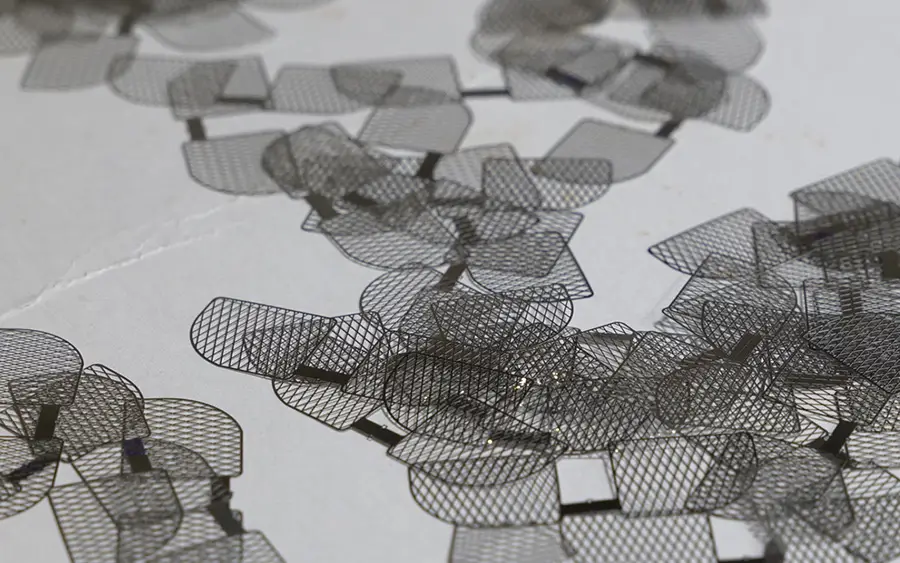

When the doors opened at the first Photofabrication Engineering, Inc. headquarters in Holliston, MA, in 1968, no one could have known that this family-run business would become the world’s leader in the photochemical etching of titanium. Yet, what started in a 4,000-square-foot facility has grown into a precision specialty manufacturing facility where the future of renewable energy, medical, electronics, and defense manufacturing is coming to life.

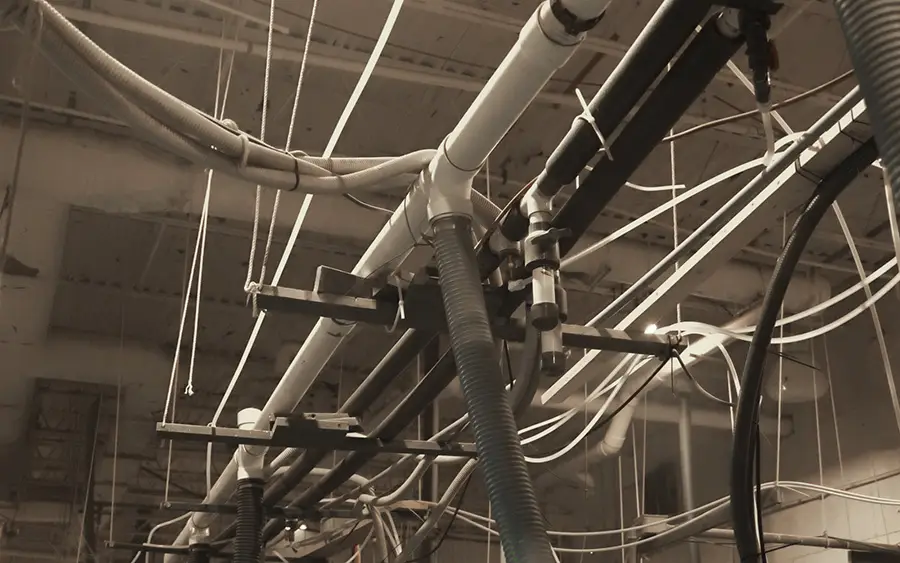

Today’s PEI, based in a 40,000-square-foot plant in Milford, Massachusetts, houses dozens of engineers, operators, quality assurance professionals, and management staff next to the latest technology and machines to support our efforts to provide unparalleled precision, reliability, service, and value.

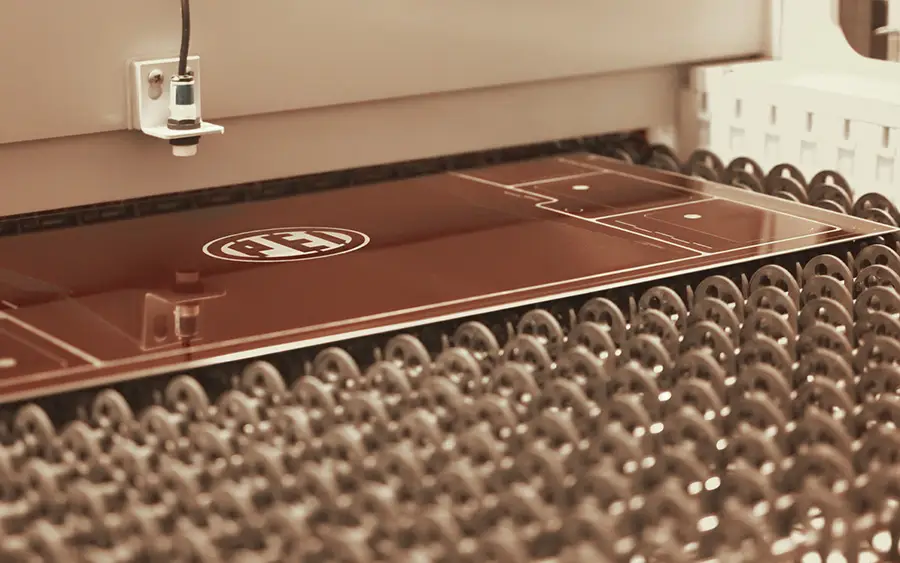

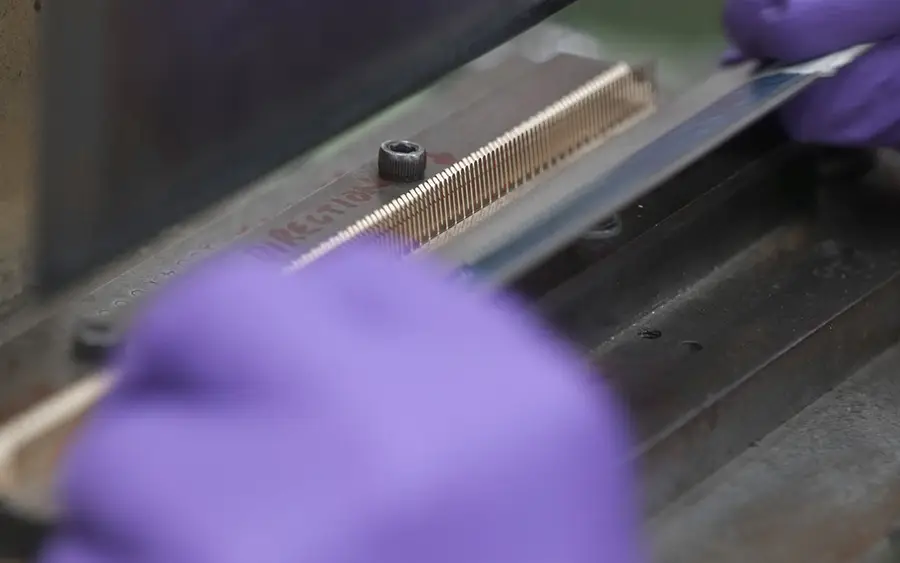

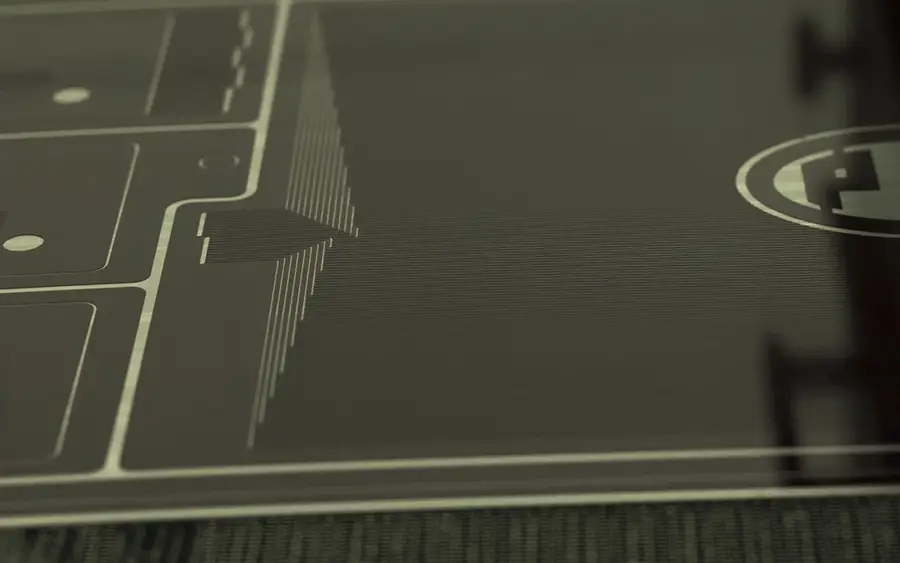

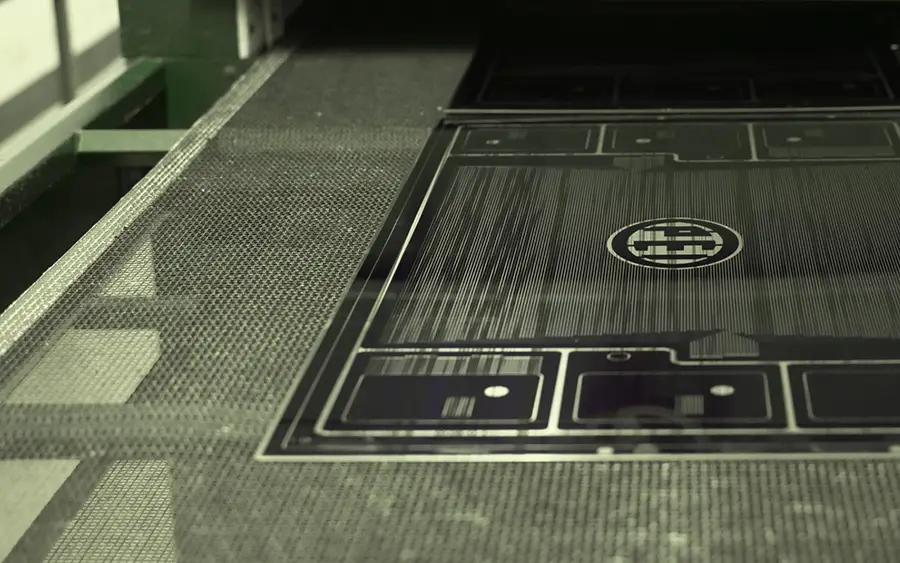

In 1968, photochemical etching was a relatively new manufacturing process that produced precise thin metal parts at the heart of components by booming semiconductor and computer manufacturers. PEI met the challenge and built a reputation as the go-to company on the East Coast. The company expanded its workforce, increased the number of machines at its plant, and brought in new senior management to help shepherd its growth.

By the 1980s, PEI had pushed the physical limitations of the Holliston facility and began looking for space to expand. Just seven miles down the road, an opportunity presented itself in Milford, offering PEI the space to grow its production footprint and house its business teams. PEI broke ground in 1983, picking 500 Fortune Boulevard as its address as an inspiration to become a Fortune 500 company.

William M. Lehrer, who joined PEI in 1977 as its president, capitalized on opportunities by introducing the company and photochemical etching to new industries, including decorative and adding capabilities to answer customers’ requests. Mr. Lehrer retired from PEI in 2009, turning the company over to his son Chip, who oversaw another expansion of the company’s business and capabilities.

The Partner Companies acquired PEI in 2021, setting the stage for a period of prolonged growth and opportunity. “PEI is a gem we’ve been pursuing for many years, and they’re a standard bearer in capability and customer service,” commented Dan Brumlik, Co-Chairman of The Partner Companies. “PEI’s expertise is a strong complement to TPC’s menu of capabilities, and their leadership team brings a robust knowledge of the manufacturing process.”

Today’s PEI features expertise throughout the facility, from engineering to manufacturing, quality assurance to program management. Plus, TPC’s support enables the company to add production capabilities to meet industry needs, including etching machinery, plant improvements, and supply chain management.

PEI is a legacy business that values and supports its people by fostering a safe and team-oriented culture while providing our customers dependable service, precision manufacturing, and exemplary quality.

We continually strive to improve our reputation for quality by driving toward zero-defect delivery by leveraging high standards, modern equipment, and exemplary people.

The well-being of our people and community is paramount to the success of our organization, so we promote and prioritize safety protocols in our culture.

We are committed to building relationships with our people and customers infused with respect, trust, and honesty. We foster this culture through attention, listening, and action.

Industries and technologies evolve when people work together to push boundaries and uncover new solutions. For over 50 years, we’ve stood shoulder to shoulder as leading companies across every market sector push forward with revolutionary changes that change the world. We are ready to share and leverage knowledge and expertise to collaborate with our customers for mutual success.

We bring decades of knowledge and experience to specialty manufacturing and are ready to uncover the next industry-changing solution.

General

Manager

Sales

Manager

HR

Manager

Director of Engineering

VP/Operations

PEI’s long history of meeting and exceeding industry standards and customer expectations began in 1968. For over 50 years, we’ve kept quality assurance at the forefront of our work by training our manufacturing teams, maintaining our equipment, and establishing rigorous internal controls. PEI holds several certifications, including ISO9001:2015, AS9100:2016, and ITAR. We adhere to MIL-STD-45662, MIL-STD-105, and ANSI/ASQC Z1.4 quality standards.

Photofabrication Engineering Inc. (PEI) is a proud member of The Partner Companies, a group of advanced specialty manufacturers who share a commitment to excellence, precision, and innovation.TPC companies operate as a consortium of capabilities, serving the defense, aerospace, medical, telecommunications, semiconductor, and renewable energy industries.

TPC supports each member entity with business growth, finance, human resources, and supply chain management expertise. The strength of TPC is the sharing of experience, materials, and resources that its members share.